Construction method of deep water pile foundation without steel pile casings

A construction method and technology for steel casings, which are applied in basic structure engineering, construction and other directions, can solve the problems of complex construction process, consumption of steel and high cost, and achieve the effect of simple construction process and steel saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

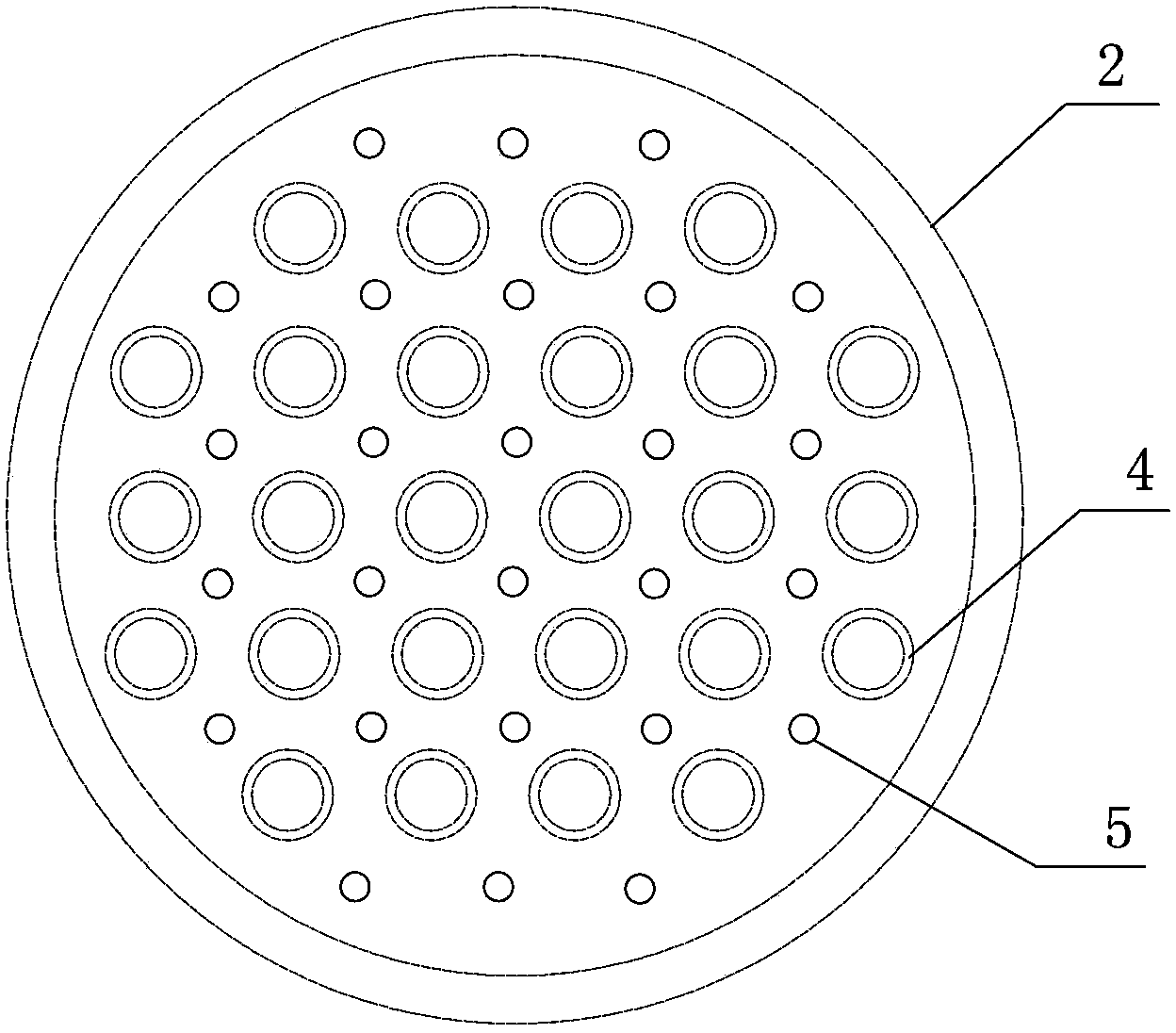

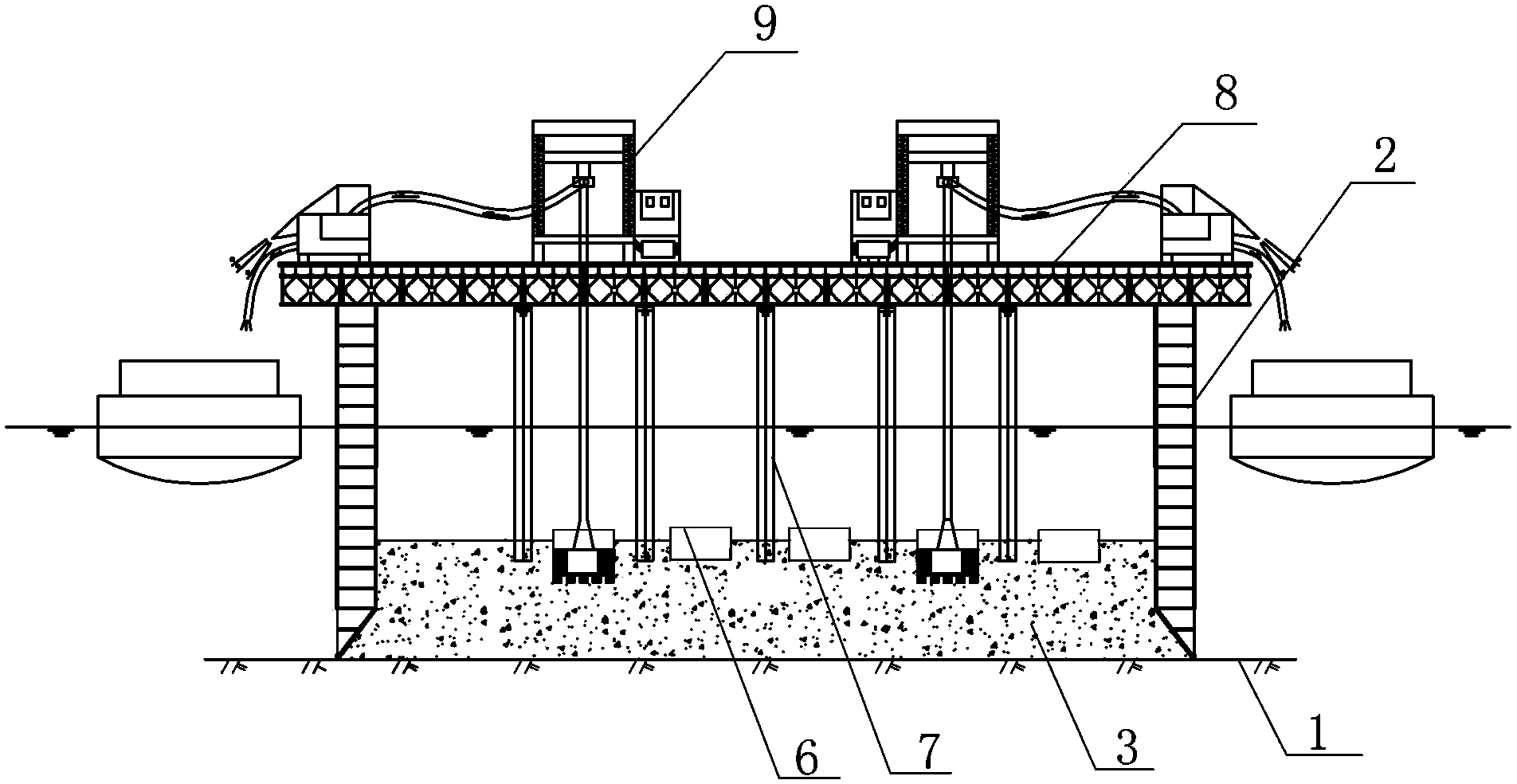

[0017] The following combination figure 1 and figure 2 , the method of the present invention is described in detail. Concrete implementation steps of the present invention are as follows:

[0018] (1), at first the overburden and the silt on the pier position on the river bed 1 are cleaned, so that the river bed 1 at the pier position is completely exposed to rock. Cleaning up the covering layer and silt can ensure that the concrete is not mixed with the soil when the cofferdam is sealed, thereby improving the quality of the bottom concrete; it can ensure that there is no soil layer on the pile hole wall when drilling, thereby ensuring the stability of the hole wall.

[0019] (2), lower the steel cofferdam 2 at the pier position. The steel cofferdam can be lowered according to the natural conditions of the site and the existing ships and machinery.

[0020] (3), pouring underwater bottom-sealing concrete 3 in the steel cofferdam 2, when the bottom-sealing concrete 3 is po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com