A method for realizing efficient real-time interaction between application layer system and basic automation

A basic automation and application system technology, applied in the field of metallurgical automatic control, can solve problems such as inability to guarantee production efficiency and inconvenient operators, and achieve improved reliability and service availability, reduced implementation difficulty, and low CPU occupied by the program Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

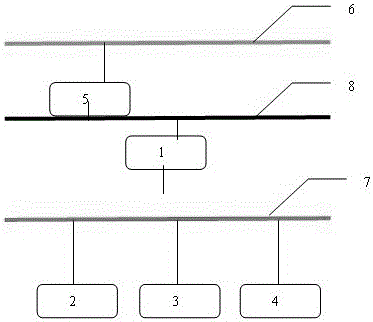

[0015] In terms of network configuration: place the interactive device and the rolling parameter model system, manufacturing execution system MES, and energy management and control system on the Ethernet, and set them in the same network segment to ensure normal interaction between the systems. Take the PING upper-layer application system to ensure the network is smooth; the interactive device uses two Gigabit network cards, and the port of the access layer switch connected to it is also a Gigabit network port. The programmable controller PLC5 is in two networks, of which One gigabit network card is connected to the ProfibusDP network 6, and the other network card is connected to the Ethernet, and is set in the same network segment as the device; in the accompanying drawing, the interactive device 1 and the programmable controller PLC5 are in the same Ethernet Among the 28 network segments, they can communicate with each other; the interactive device 1, the rolling parameter mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com