Semi-automatic backing welding method for consumable electrode of stainless steel gasket of aluminum alloy plate

A technology of aluminum alloy plate and welding method, which is applied in the direction of welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of stainless steel liner breakdown or damage, unstable root welding quality, etc., and solve the problem of internal quality Instability problems, shortening the production cycle, and avoiding the effects of breakdown or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

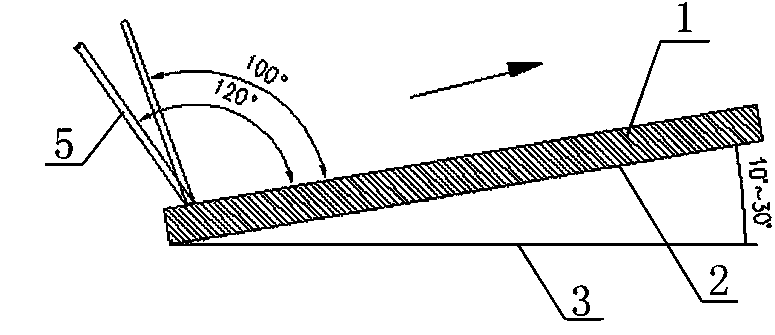

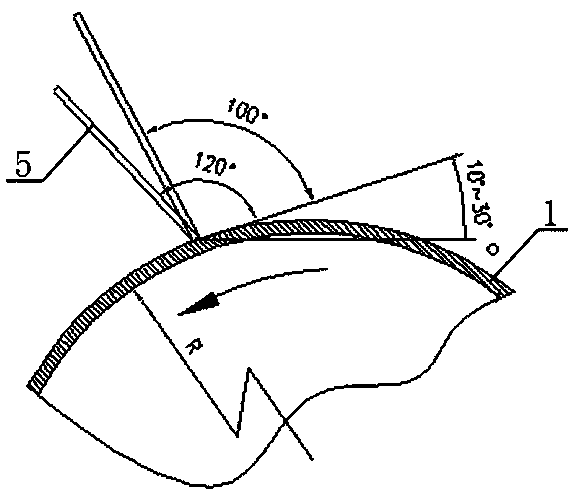

[0024] Industrial CO with serial drawing numbers such as RS803 designed by the Petrochemical Department of Hangyang Co., Ltd. 2 In the evaporator, the thickness of the cylinder and the head is 30-35mm, and the volume is small, and the internal space is narrow. In order to facilitate the welding of the cylinder, the two sides of the head and the cylinder are connected by a stainless steel gasket single-sided welding process. The application of the welding technology of the present invention can ensure the welding quality and greatly shorten the manufacturing cycle.

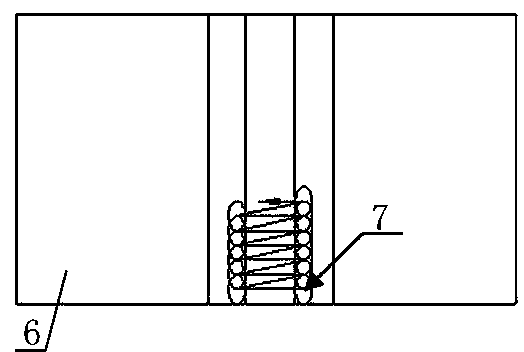

[0025] After many tests, the back stainless steel liner was peeled off, and no breakdown was found. The back of the weld is beautifully formed. After X-ray inspection, it was qualified once and there was no repair case.

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com