Flexible and automatic cam-extruded metal mesh belt pressing device

A technology of metal mesh belt and pressure net device, which is applied in auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve problems such as difficulty in completing order tasks on time, difficulty in recruiting and management, and large influence of human factors, so as to ease recruitment and management difficulties, increased utilization, and reduced workforce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

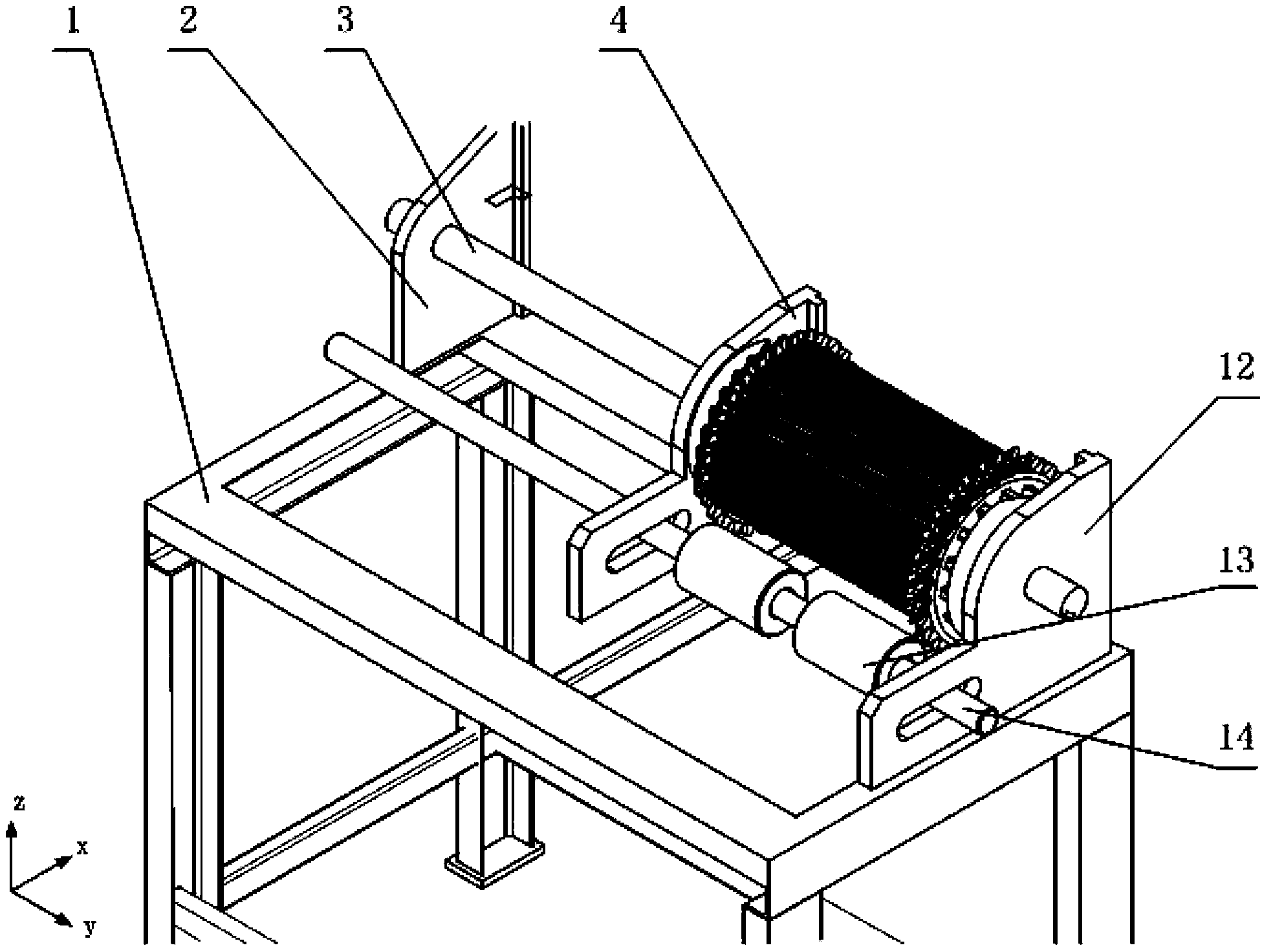

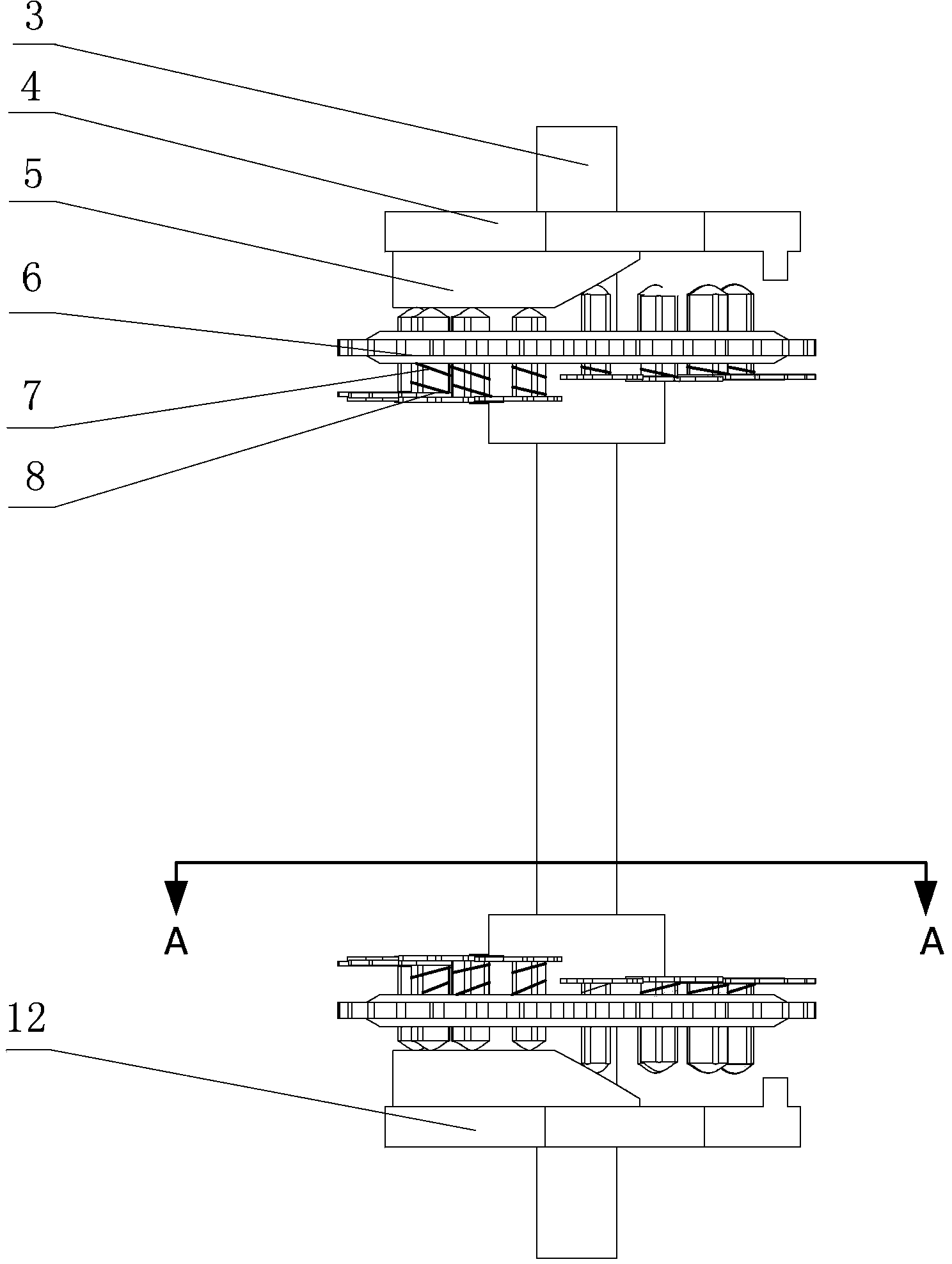

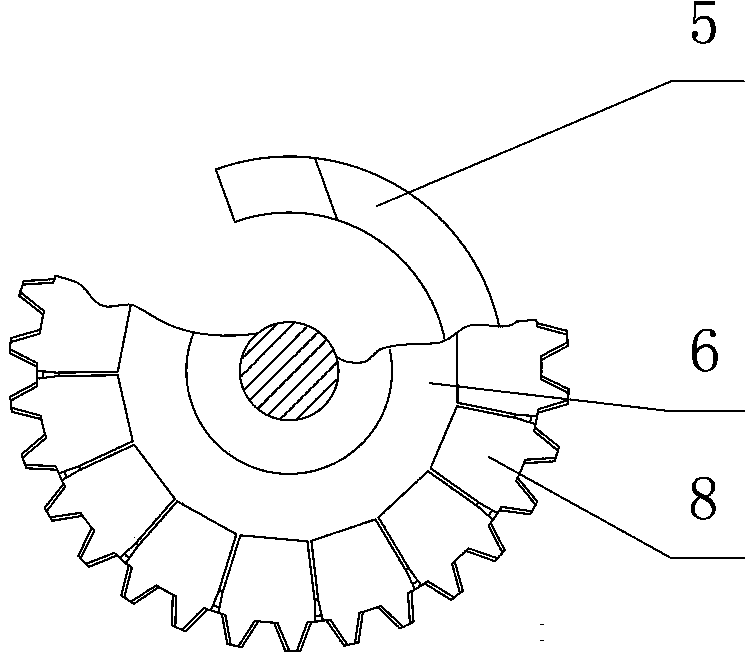

[0031] as attached figure 1 , attached figure 2 , attached image 3 , and attached Figure 4 As shown, the present invention includes a frame 1, a left side wall 2, a drive shaft 3, an adjustable wall 4, two cams 5, two large sprockets 6, several springs 7, and several sprockets Compression teeth 8, a right side wall 12, two pressing wheels 13, a pressing shaft 14; On the moving guide rail of the frame 1, it is located between the left side wall 2 and the right side wall 12, parallel to the left side wall 2 and the right side wall 12; the drive shaft 3 is installed on the adjustable wall 4 and the left side wall along the y-axis direction 2 and the right side wall 12; two large sprockets 6 are installed on the drive shaft 3 in the middle of the adjustable wall 4 and the right side wall 12, and are respectively close to the adjustable wall 4 and the right side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com