Production Process of Titanium Dioxide Special Color Masterbatch for Automotive Plastics

A production process and color masterbatch technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effects of low processing torque, excellent anti-yellowing ability, and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The invention provides a production process of titanium dioxide special-purpose color masterbatch for automobile plastics, which includes the following steps: ore dressing, crushing, acid hydrolysis, sedimentation, pressure filtration, concentration of titanium liquid, hydrolysis, water washing, bleaching, rinsing, salt treatment, diaphragm pressing Filtration, calcination, crushing, control the content of arsenic in the beneficiation step to less than 5ppm, and add 0.5% K in the salt treatment step 2 CO 3 , 0.15% H 3 PO 4 , all with TiO 2 To ensure that the specific surface area of the obtained titanium dioxide is 8-15m 2 / g. In the beneficiation step, the heavy metal content is lower than 1000ppm, in the washing step, the iron content is controlled to be lower than 50ppm, and the temperature control range in the calcination process is 10°C.

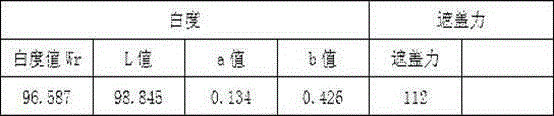

[0011] The main parameters of the special color masterbatch titanium dioxide for automotive plastics obtained by the abo...

Embodiment 2

[0014] The invention provides a production process of titanium dioxide special-purpose color masterbatch for automobile plastics, which includes the following steps: ore dressing, crushing, acid hydrolysis, sedimentation, pressure filtration, concentration of titanium liquid, hydrolysis, water washing, bleaching, rinsing, salt treatment, diaphragm pressing Filtration, calcination, crushing, control the content of arsenic in the beneficiation step to less than 5ppm, and add 0.5% K in the salt treatment step 2 CO 3 , 0.15% H 3 PO 4 , all with TiO 2 To ensure that the specific surface area of the obtained titanium dioxide is 8m 2 / g. In the beneficiation step, the heavy metal content is lower than 1000ppm, in the washing step, the iron content is controlled to be lower than 50ppm, and the temperature control range in the calcination process is 10°C.

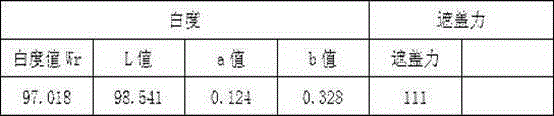

[0015] The main parameters of the special color masterbatch titanium dioxide for automotive plastics obtained by the above ...

Embodiment 3

[0018] The invention provides a production process of titanium dioxide special-purpose color masterbatch for automobile plastics, which includes the following steps: ore dressing, crushing, acid hydrolysis, sedimentation, pressure filtration, concentration of titanium liquid, hydrolysis, water washing, bleaching, rinsing, salt treatment, diaphragm pressing Filtration, calcination, crushing, control the content of arsenic in the beneficiation step to less than 5ppm, and add 0.5% K in the salt treatment step 2 CO 3 , 0.15% H 3 PO 4 , all with TiO 2 To ensure that the specific surface area of the obtained titanium dioxide is 15m 2 / g. The heavy metal content in the beneficiation step is lower than 1000ppm, the iron content in the washing step is controlled to be lower than 40ppm, and the temperature control range in the calcination process is 10°C.

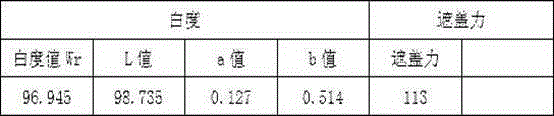

[0019] The main parameters of the special color masterbatch titanium dioxide for automotive plastics obtained by the above p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com