Composite rebar corrosion inhibitor and preparation method thereof

A technology of composite steel bars and rust inhibitors, applied in the field of building materials, can solve the problems of concrete strength reduction, affecting concrete performance, and incompatibility, and achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

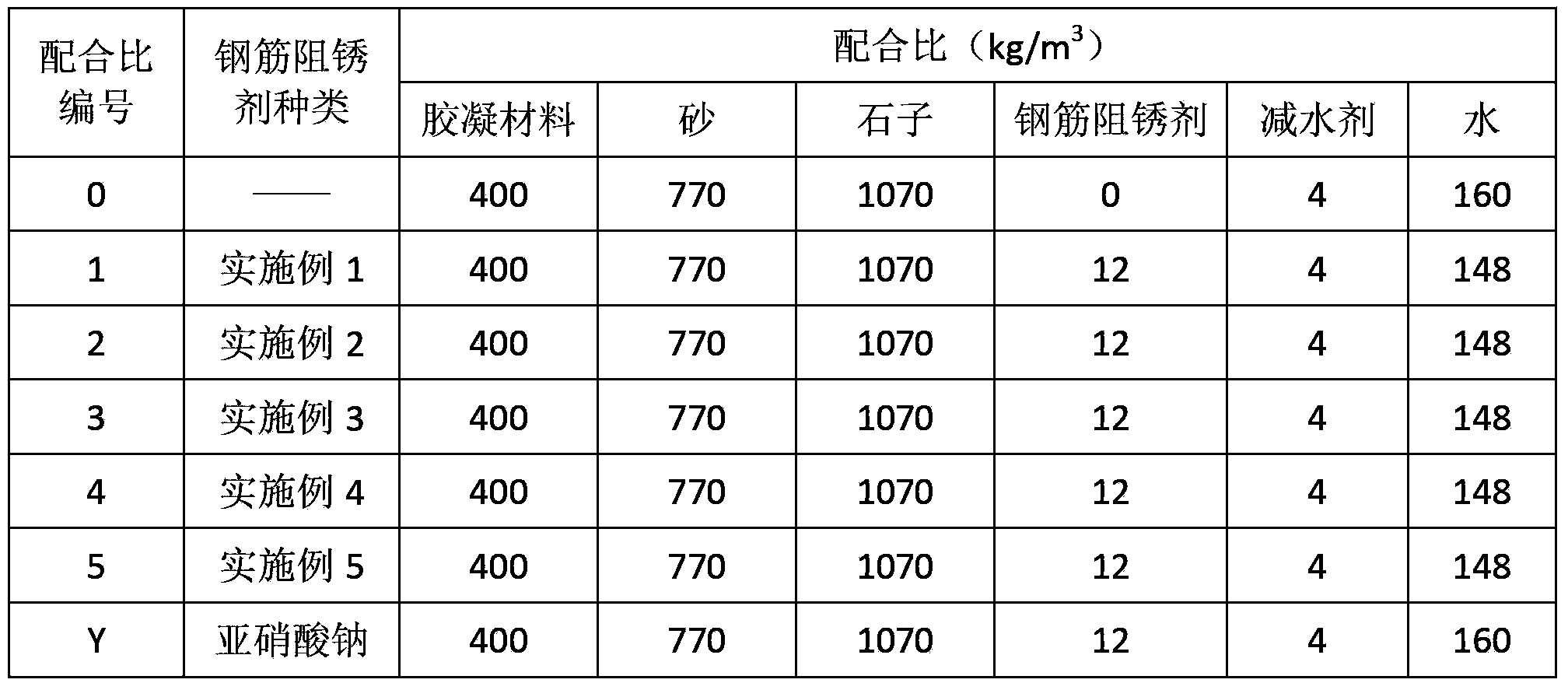

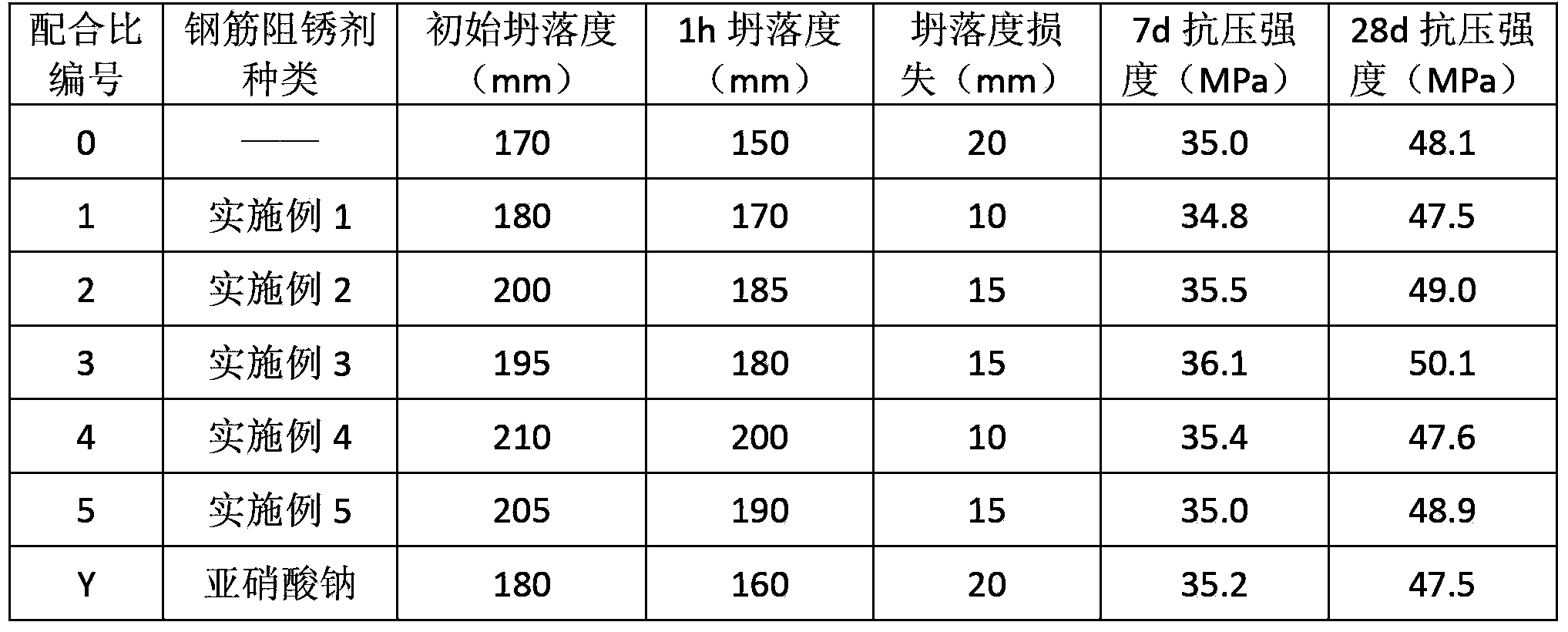

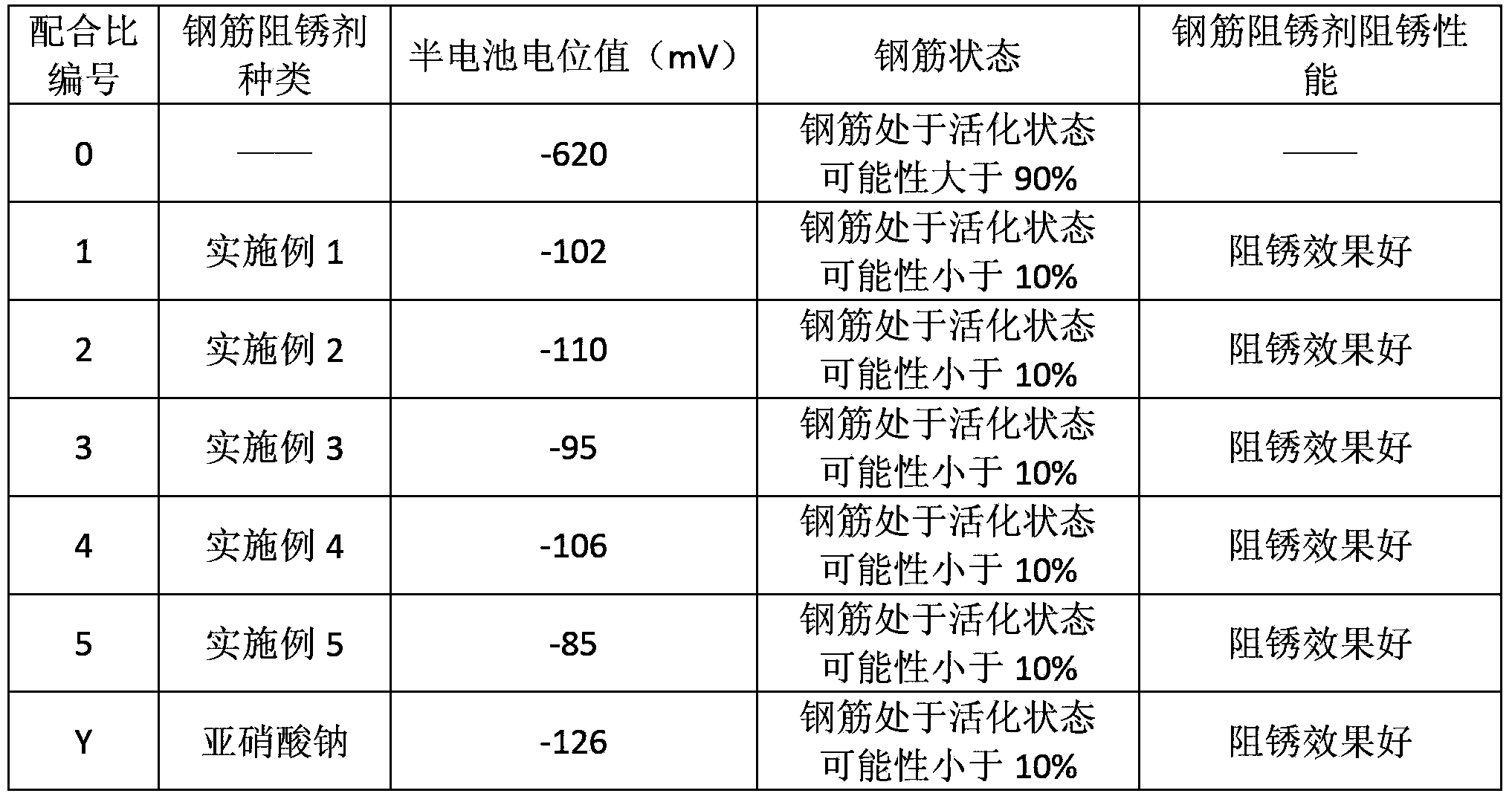

Examples

Embodiment 1

[0022] Weigh 10kg of ethanolamine, 10kg of dicyclohexylamine, and 10kg of sodium benzoate, and add the above-mentioned raw materials into 70kg of water in turn, and stir evenly.

Embodiment 2

[0024] Weigh 20kg of N-methylethanolamine, 5kg of ethylenediamine, and 1kg of sodium benzoate, and add the above raw materials into 74kg of water in sequence, and stir evenly.

Embodiment 3

[0026] Weigh 10kg of N-methylethanolamine, 5kg of N,N-dihydroxyethylethylenediamine, 2kg of methylamine, and 5kg of sodium benzoate, and add the above raw materials into 78kg of water in sequence, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com