Decorative integrated self-insulation recycled concrete block and its manufacturing method

A technology of concrete blocks and recycled concrete, which is applied in the field of building materials manufacturing, can solve the problems of unfavorable environmental protection, material cost, labor cost waste, and delay in construction period, so as to save the construction of scaffolding, achieve significant economic benefits, and reduce the construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

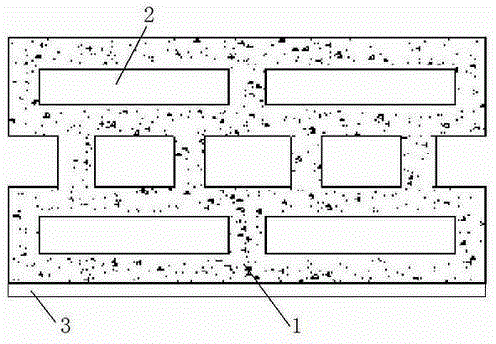

[0014] Decorative integrated self-insulation recycled concrete block of the present invention, such as figure 1 As shown, it includes a concrete block 1, and the raw materials of the concrete block 1 include water, recycled coarse aggregate, mine tailings admixture, slag after active treatment and finely ground fine particles (reaching the I-level fly ash index ), 42.5 cement, machine-made medium sand and vitrified microspheres, a number of thermal insulation through holes 2 are arranged in the concrete block, and a decorative paint layer 3 is provided on one side of the outer wall of the concrete block.

[0015] The ratio of raw materials for the above concrete block is: 243~297kg of water, 1084.5~1325.5kg of recycled coarse aggregate with a particle size of 5~10mm, 31.5~38.5kg of mine tailings admixture, finely ground slag after active treatment Fine particles 86.4~105.6kg, 42.5 cement 314.1~383.9kg, machine-made medium sand 270.9~331.1kg, vitrified microbeads 3.15~3.85kg. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com