A kind of polymerization reaction device and its application

A technology of polymerization reaction and polymerization reactor, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., and can solve problems such as poor performance of isoprene rubber and difficulty in glue transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example is used to illustrate the preparation of the isoprene rubber provided by the present invention.

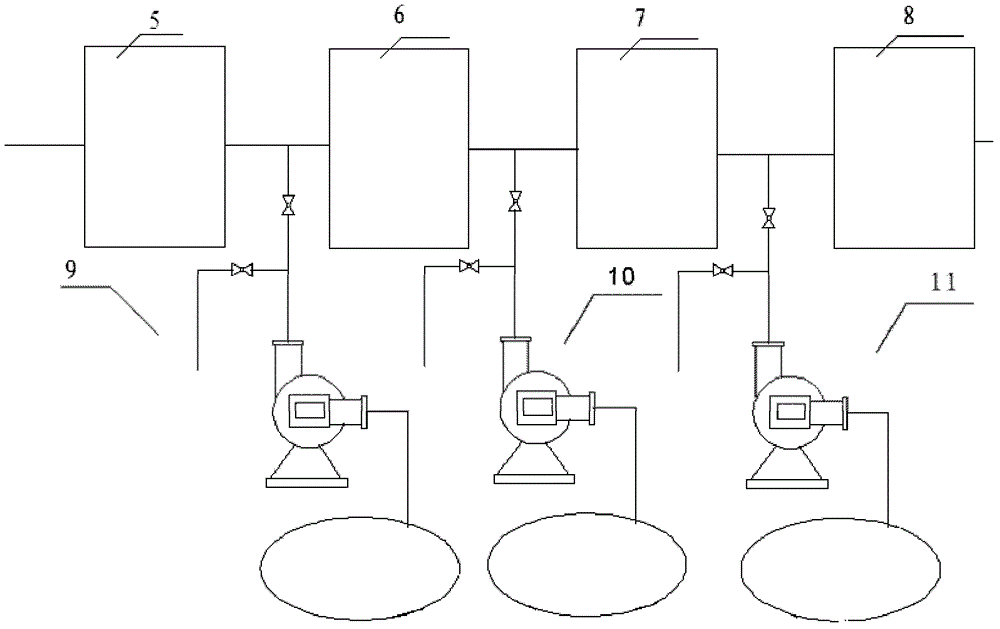

[0039] according to figure 2 The polymerization reaction device shown is for the preparation of isoprene rubber, wherein, the capacity of all polymerization reaction tanks is 5L. With the flow rate of isoprene monomer at 0.93L / h, the flow rate of n-hexane at 5L / h, the n-hexane solution of neodymium catalyst (the concentration of catalyst is 0.5×10 -2 mol / L) is passed into the first kettle 5 with a flow velocity of 0.29L / h. Based on the total weight of the isoprene monomer, n-hexane and catalyst, the total content of isoprene monomer and isoprene rubber in the first kettle 5 is 15.3% by weight. After 48 minutes of polymerization in the first kettle 5, the conversion rate of isoprene monomer was 58%, and the first supplementary solvent device 9 between the first kettle 5 and the second kettle 6 was opened. Adjust the frequency of the metering pump to be 28Hz,...

Embodiment 2

[0044] This example is used to illustrate the preparation of the isoprene rubber provided by the present invention.

[0045] according to figure 2 The polymerization reaction device shown is for the preparation of isoprene rubber, wherein, the capacity of all polymerization reaction tanks is 5L. With the flow rate of isoprene monomer at 1.1L / h, the flow rate of n-hexane at 4.9L / h, the n-hexane solution of neodymium catalyst (the concentration of catalyst is 0.6×10 -2mol / L) is passed into the first kettle 5 with a flow velocity of 0.278L / h. Based on the total weight of the isoprene monomer, n-hexane and catalyst, the total content of isoprene monomer and isoprene rubber in the first kettle 5 is 17.3% by weight. After 47.8 minutes of polymerization in the first kettle 5, the conversion rate of isoprene monomer was 60%, and the first additional solvent addition device 9 between the first kettle 5 and the second kettle 6 was opened. Adjust the frequency of the metering pump to...

Embodiment 3

[0050] This example is used to illustrate the preparation of the isoprene rubber provided by the present invention.

[0051] according to figure 2 The polymerization reaction device shown is for the preparation of isoprene rubber, wherein, the capacity of all polymerization reaction tanks is 5L. With the flow rate of isoprene monomer at 1.05L / h, the flow rate of n-hexane at 3.62L / h, the n-hexane solution of neodymium catalyst (the concentration of catalyst is 0.5×10 -2 mol / L) is passed into the first kettle 5 with a flow velocity of 0.33L / h. Based on the total weight of the isoprene monomer, n-hexane and catalyst, the total content of isoprene monomer and isoprene rubber in the first kettle 5 is 21% by weight. After 60 minutes of polymerization in the first kettle 5, the conversion rate of isoprene monomer was 60%, and the first additional solvent addition device 9 between the first kettle 5 and the second kettle 6 was opened. Adjust the frequency of the metering pump to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com