Motor rotor surface pickling burring technology

A motor rotor and rotor surface technology, applied in the field of motor manufacturing, can solve the problems affecting the service life of the rotor, affecting the effect of pickling, affecting the performance of the motor, etc., to improve the treatment effect and production efficiency, improve the effect of pickling treatment, and avoid corrosion Sexually destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

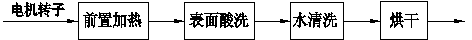

[0021] see figure 1 , the process steps of the process of the present invention are:

[0022] Step 1: Pre-heat the rotor;

[0023] Step 2: Pickle the surface of the rotor with the prepared acid solution;

[0024] Step 3: Clean the surface of the rotor with water;

[0025] Step 4: Dry the cleaned rotor.

[0026] For the pre-heating treatment of the rotor, an infrared heating device can be used. Generally, the surface of the rotor is heated to 60 ℃ ~ 80 ℃; the acid solution can be hydrochloric acid solution or phosphoric acid solution. When phosphoric acid solution is used, the ratio of phosphoric acid to water is usually The ratio is 1:3~5; the drying of the cleaned rotor can be done by an infrared drying device.

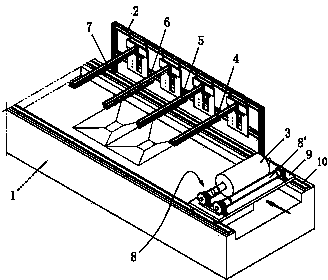

[0027] In the process operation of the first step to the fourth step, the rotor rotates along its axis, and the rotor rotates continuously under the operating conditions of each process, so that each part of the rotor surface can be treated correspondingly, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com