Annular core optical fiber sensor based on annular chamber decline

An optical fiber sensor and annular core technology, which is applied in the measurement of phase influence characteristics, etc., can solve the problem that it is difficult to put into practical use, and achieve the effects of convenient chemical or physical modification, high cost performance and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

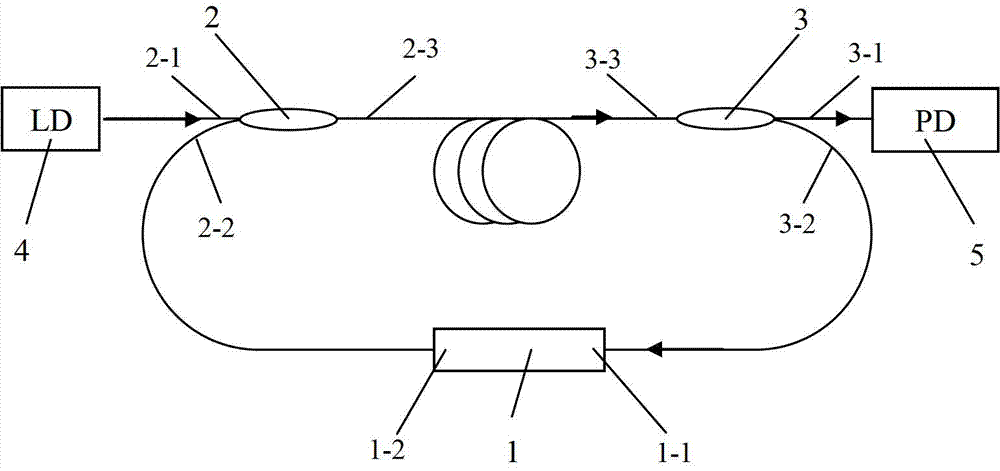

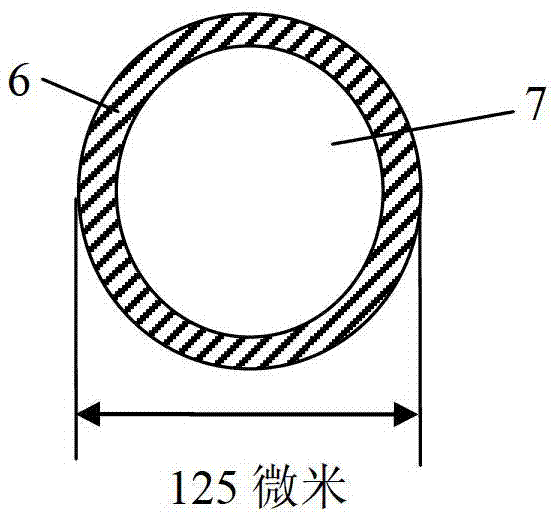

[0030] combine Figure 1-Figure 4 , a surface ring core optical fiber sensor based on optical fiber ring cavity ring down The sensing unit is a ring core 6 with a length of 3 cm and an outer diameter of 125 microns. Connected with two 1×2 fiber optic couplers 2 and 3 with a split ratio of 99.0:1.0 and one end 2-2, 3-2 with a split ratio of 99.0, two 1×2 fiber couplers have one port on one side 2 -3 and 3-3 are interconnected to form an annular cavity. The pulse light source 4 and the detector 5 are respectively connected to one end 2-1 and 3-1 of two 1×2 fiber couplers with a splitting ratio of 1.0. Wherein the ring-core fiber 1 is connected to the fiber couplers 2 and 3 by aligning the two ends 1-1 and 1-2 of the ring-core fiber 1 with the axes of the coupler fibers 3-2 and 2-2 and directly welding ( image 3 ), and then perform fusion tapering at the solder joint ( Figure 4 ), through the tapered transition zone 8 to achieve energy coupling. When the light source 4 is i...

Embodiment 2

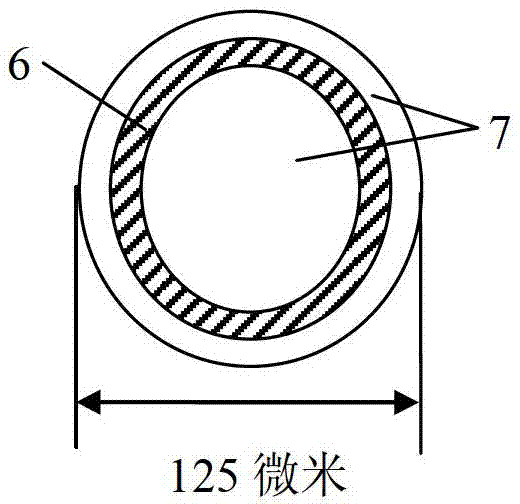

[0032] combine figure 1 , Figure 5 and Figure 6 , a ring-core optical fiber sensor sensing unit based on optical fiber ring cavity ringdown is a ring-core optical fiber 1 with a ring-core 6 outer diameter of 100 microns, and its two ends 1-1 and 1-2 are respectively connected with two splitting ratios of 99.0: 1.0 1×2 fiber coupler 2, 3 with a splitting ratio of 99.0 and one end 2-2, 3-2 connected, two 1×2 fiber couplers have 1 output port on one side 2-3 and 3- 3 are interconnected with each other to form an annular cavity. The pulse light source 4 and the detector 5 are respectively connected to one end 2-1 and 3-1 of two 1×2 fiber couplers with a splitting ratio of 1.0. The output end 1-2 of the ring-core optical fiber 1 and the optical fiber 2-2 end of the coupler 2 are directly welded through axial alignment, and then melted and tapered at the welding point, and the energy coupling is realized by using the tapered transition zone 8 ; And the incident end 1-1 of ring...

Embodiment 3

[0034] combine figure 1 and Figure 7 , a ring-core optical fiber sensor based on optical fiber ring cavity ring down, differs from embodiment 1 in that a thin metal film or dielectric film 9 is plated on the surface of the sensing part of the ring-shaped surface core to increase the sensitivity of the sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com