Thin film transistor and method for fabricating the same

一种薄膜晶体管、栅绝缘膜的技术,应用在晶体管、半导体/固态器件制造、半导体器件等方向,达到高电子迁移率、良好输出饱和特性、工艺简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the thin film transistor structure of the present invention will be described with reference to the accompanying drawings.

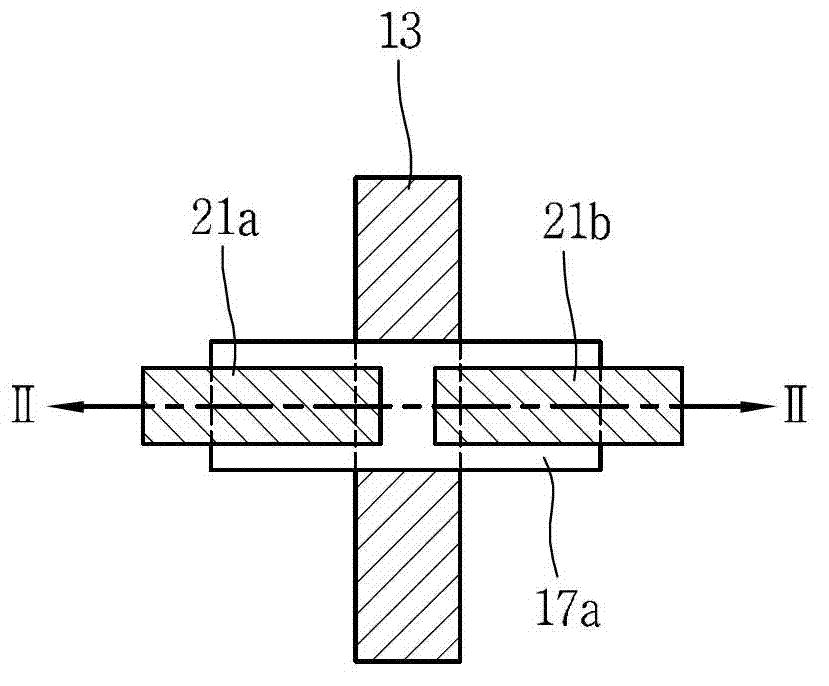

[0049] Image 6 is a plan view of the thin film transistor of the present invention.

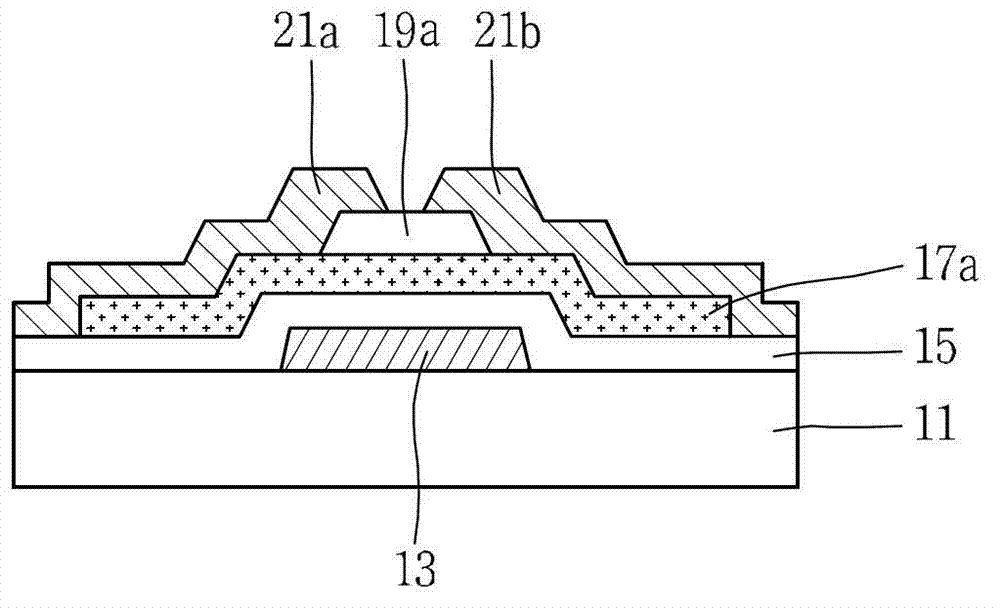

[0050] Figure 7 is a cross-sectional view of the thin film transistor structure of the present invention along line VII-VII.

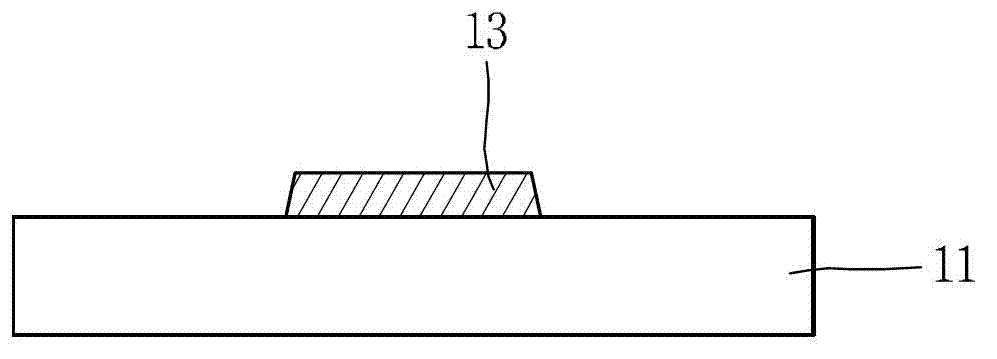

[0051] Such as Image 6 with Figure 7 As shown, the thin film transistor according to the present invention includes: a gate electrode 103, patterned on a substrate 101 to have a given width and length, and including a vertical electrode portion 103B and a plurality of horizontal electrode portions 103A separated by fixed intervals a gate insulating film 107 formed over the entire surface of the substrate 101 including the gate electrode 103; an active pattern 109a formed into a given shape over the plurality of horizontal electrode portions 103A on the gate insulating film 107; an etching stopper film pattern 113A, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com