Short fiber with microfiber structure, filter felt, and manufacturing method of filter felt

A technology of microfiber structure and short fiber, which is applied in the direction of filtration and separation, fiber treatment, separation methods, etc., can solve the problems that it is difficult to meet the requirements of 2.5 micron dust filtration, the service life is not enough, and it is easy to fall off, so as to improve the control of air pollution Ability, improve filtering accuracy, increase the effect of collision probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

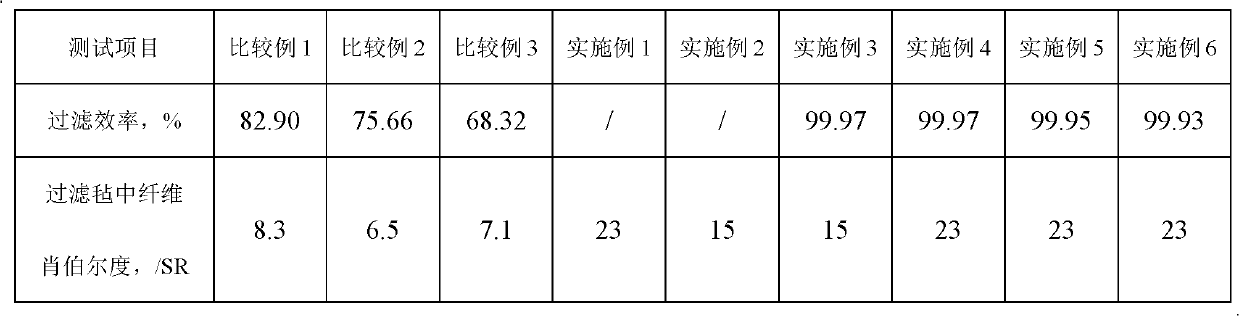

Examples

Embodiment 1

[0046] (1) Cutting fiber:

[0047] Using the 1600-denier para-aramid filament coil of the Kevlar 29 brand produced by DuPont, 50 coils are plied to form a 80,000-denier tow, and then cut with a guillotine cutter to form a length of 90 mm. of short fibers.

[0048] (2) Preparation of expansion aids:

[0049] In the pretreatment still, 75 kilograms of dioctyl phthalates are dissolved in 425 kilograms of ethanol, stir and mix uniformly, prepare bulking aid, the mass percent of described dioctyl phthalates in ethanol solution is 15%.

[0050] (3) Dipping treatment

[0051] Take by weighing 50 kilograms of cut short fibers and place them in the pretreatment kettle with 500 kilograms of expansion aids, after stirring evenly, soak for 2 hours at normal temperature in the pretreatment kettle, remove the oil agent on the fiber surface, and make The fiber swells, making the structure of the fiber loose. Then take out the short fibers loosened by swelling and wash them with pure wat...

Embodiment 2

[0060] (1) Cutting fiber:

[0061] The 1600-denier para-aramid filament rolls produced by Yantai Taihe Co., Ltd. were used to ply 50 filament rolls to form 80,000-denier tows, which were then cut with a guillotine cutter to form short fibers of 90 mm.

[0062] (2) Preparation of expansion aids:

[0063] In the pretreatment still, 75 kilograms of dioctyl phthalates are dissolved in 425 kilograms of ethanol, stir and mix uniformly, prepare bulking aid, the mass percent of described dioctyl phthalates in ethanol solution is 15%.

[0064] (3) Dipping treatment

[0065] Take by weighing 50 kilograms of cut short fibers and place them in the pretreatment kettle with 500 kilograms of expansion aids, after stirring evenly, soak for 2 hours at normal temperature in the pretreatment kettle, remove the oil agent on the fiber surface, and make The fiber swells, making the structure of the fiber loose. Then take out the short fibers loosened by swelling and wash them with pure water. ...

Embodiment 3

[0072] With the finished product of a kind of para-aramid short fiber containing microfiber structure obtained in Example 2, the short fiber mass is opened, and then the short fiber after opening is made into a homogeneous mixture, using standard carding and crossing Winding equipment that converts these staple fibers into cross-lapped fine mats that are roughed or slightly reinforced on a standard needle loom, two or more sheets of fine mats are combined, and needled on both sides to produce the resulting The filter felt, the weight of the filter felt is 450g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Base weigh | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com