Interference exposure system and exposure method thereof

A technology of interference exposure and exposure system, which is used in microlithography exposure equipment, photolithography process exposure devices, etc., and can solve the problems that the resolution is not as good as that of positive photoresist and the high resolution limitation of interference lithography.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

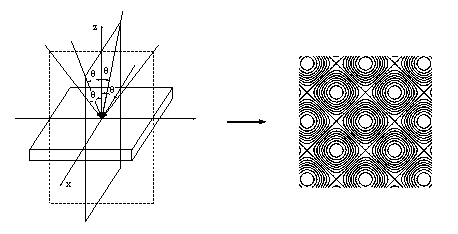

no. 1 example

[0059] refer to Figure 4 As shown, the interference exposure system includes a beam splitter 1 , two shutters 21 , 22 , two mirrors 31 , 32 , a glue-coated base 4 , a rotating mechanism 5 and a phase compensator 6 . The incident light 10 passes through the beam splitting device 1 and is split into two beams of light with equal intensity and same polarization state, which are spatially symmetrical, namely a first beam 101 and a second beam 102 . The first light beam 101 and the second light beam 102 are respectively incident on the surface of the glue-coated substrate 4 at the same incident angle after passing through the mirrors 31 and 32 . The two shutters 21 and 22 are respectively arranged in the interference arm where the first light beam 101 and the second light beam 102 are located, and the phase compensator 6 is arranged in the first interference arm where the first light beam 101 is located. The phase compensator 6 can be a wave plate or a liquid crystal phase retarder...

no. 2 example

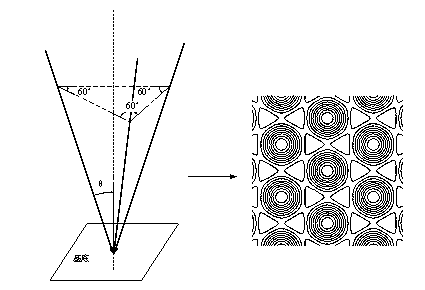

[0063] refer to Figure 9 As shown, the interference exposure system of this embodiment includes a beam splitter 1 , three shutters 21 , 22 , 23 , three mirrors 31 , 32 , 33 , a glue-coated substrate 4 and a phase compensator 6 . This embodiment can also realize the function of forming dense holes and dense column patterns distributed in regular hexagons on the positive photoresist.

[0064] The incident light 20 can be collimated monochromatic coherent light, generally a laser with a wavelength from deep ultraviolet to about 450nm; the incident light passes through the beam splitter 1, is divided into equal intensity and same polarization state, and is projected onto the substrate at a spatial angle 3 beams of light at 120 degrees, namely the first beam 201 , the second beam 202 and the third beam 203 . The three beams of light respectively pass through a reflector 31, 32, 33, are incident at the same incident angle and converge on the surface of the glue-coated substrate. ...

no. 3 example

[0069] This embodiment can realize the formation of regular quadrilateral dense hole and dense column patterns on the positive photoresist. The interference exposure system includes a beam splitter 1 , phase compensators 61 , 62 , four mirrors 31 , 32 , 33 , 34 and a glue-coated substrate 4 . Compared with Embodiment 1, this embodiment omits the rotating mechanism.

[0070] The incident light 30 passes through the beam splitting device 1 and is divided into four beams of equal intensity and same polarization state, which are mapped to the substrate and form an angle of 90 degrees with each other, namely the first beam 301, the second beam 302, the third beam 303 and The fourth light beam 304 . After the four beams of light pass through the reflectors 31, 32, 33, and 34 respectively, they are incident and converged on the surface of the glue-coated substrate 4 with the same incident angle, wherein the first beam 301 and the second beam 302, the third beam 303 and the fourth be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com