Infusion cover for sterile filling

A technology for aseptic filling and infusion caps, which is applied in the field of infusion drug packaging, can solve the problems of many production equipment, difficult process control, high material cost, etc., and achieve the effect of simple overall structure, avoiding the assembly process of caps, and less puncture debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

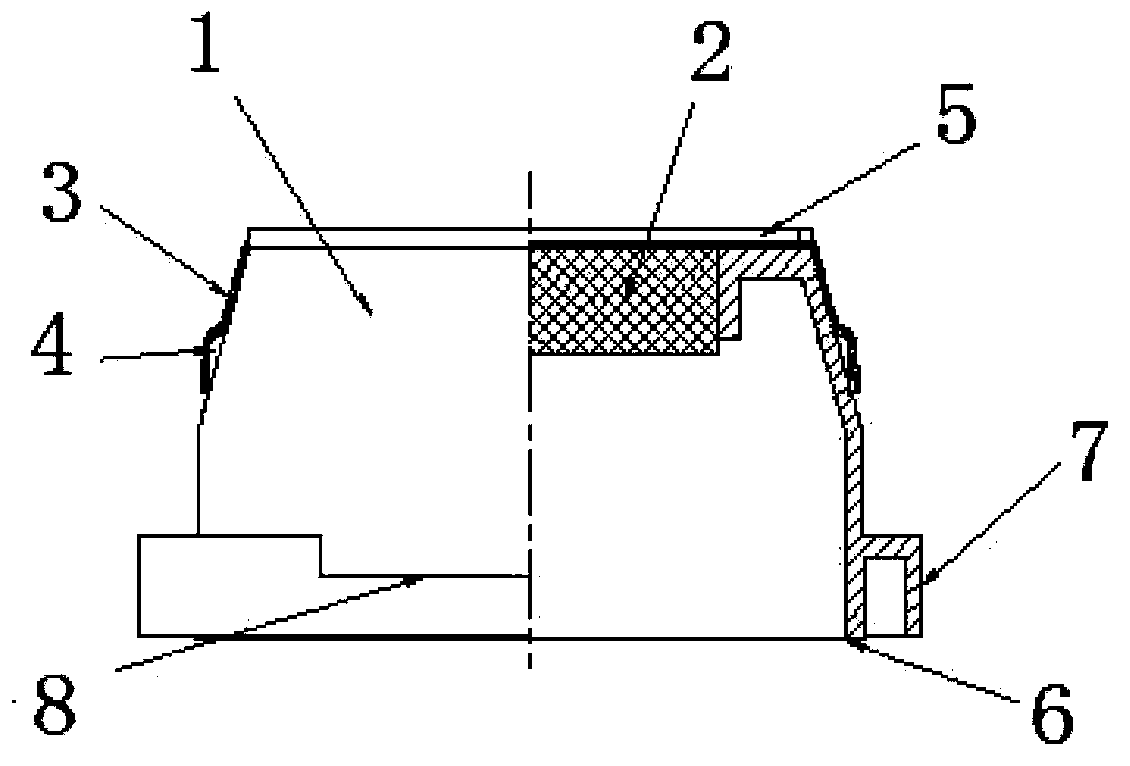

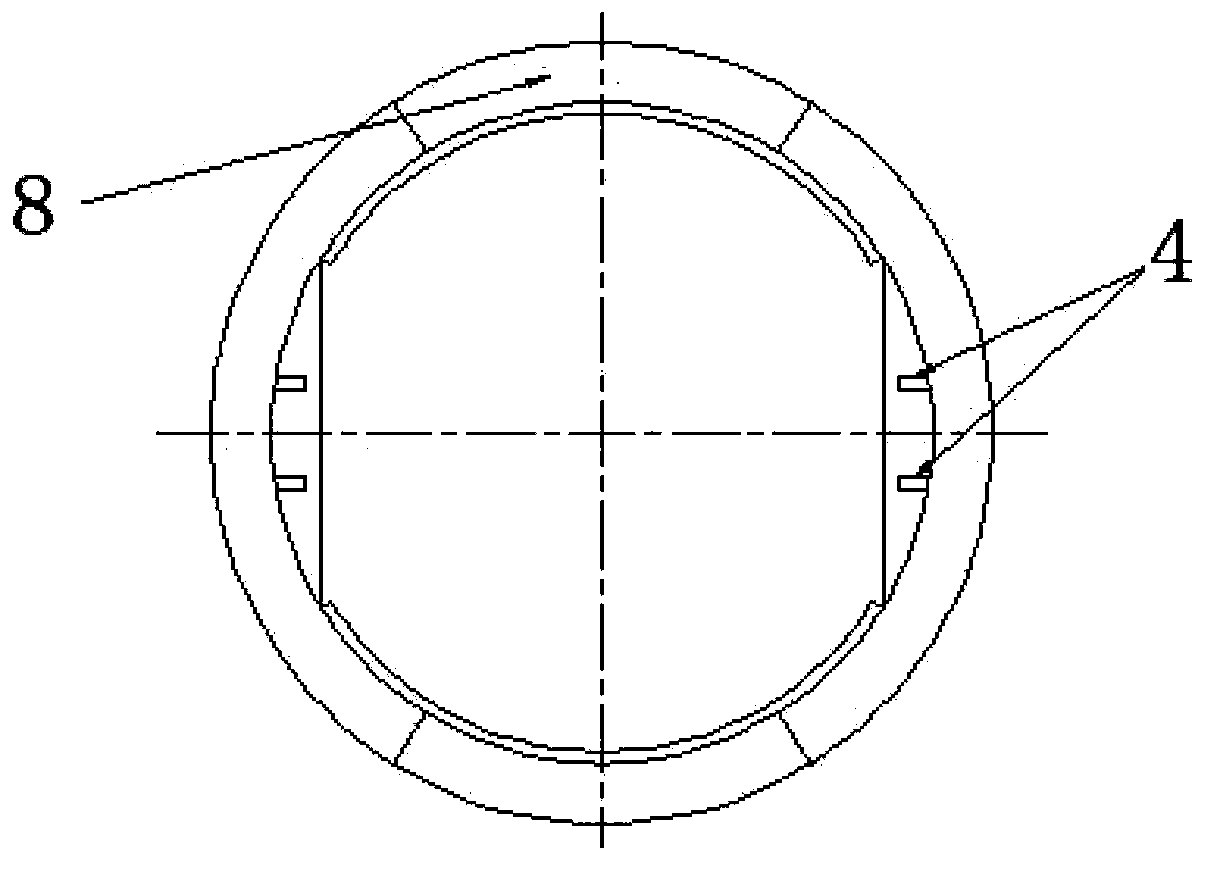

[0017] like Figure 1~Figure 2 A cap for aseptic filling and infusion is shown, which includes a cap body 1, a sealing gasket 2 is provided in the middle of the outer end surface of the cap body 1, and the cap body 1 and the sealing gasket 2 are connected as a whole. The infusion cap also includes a protective film 3 covering the outer end surface of the cap body 1 . The protective film 3 is used for isolating the gasket from the outside, free from pollution, and convenient for opening. The side wall of the cover body 1 is an inclined wall, which is used for positioning the infusion cover when walking on the production line track and welding with the bottle mouth. A bump 4 is provided on the side wall of the cover body 1 . The protection film 3 protrudes from an extension end covering the bump 4 . After the bump 4 is covered by the protective film, the two ends of the protective film are raised and gaps are formed, which is convenient for tearing the protective film.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com