High viscosity rubber composite of tire airtight layer

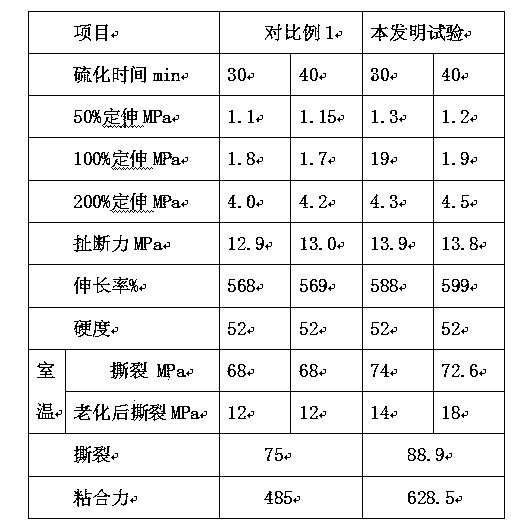

A composition and inner liner technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of poor viscosity, low calorific value, easy material breakage, etc., to improve the viscosity, improve stretching and tearing The effect of cracking strength and improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A high-viscosity tire inner liner sizing compound composition, the components of the sizing compound composition and the parts by weight of the content thereof are:

[0034] Bromobutyl gum 80

[0035] 1742 butyl rubber 20

[0036] Carbon black N660 35

[0037] Diatomaceous earth 25

[0039] Stearic acid 1.3

[0040] 4m2 zinc oxide 3

[0041] 2 resin 6

[0042] Naphthenic oil 6.5

[0043] Promote DM 1.6

[0044] 7020 sulfur 0.63

[0045] The production of rubber material is divided into two stages of mixing production. The first stage of rubber material formula adds bromobutyl rubber, 1742 butyl rubber, carbon black N660, diatomaceous earth, magnesium oxide, stearic acid, 4m2 zinc oxide, 2 resins, and the rest The compounding agent is added in the second-stage rubber formula. The two-stage rubber materials are mixed and manufactured in the internal mixer respectively, then pounded on the tablet press, and then the tablets are cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com