Bicolor-effect fabric and preparation method thereof

A fabric, together technology, applied in the field of two-color effect fabric and its preparation, achieves the effect of simple preparation method, shortened production cycle, and satisfying overall aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

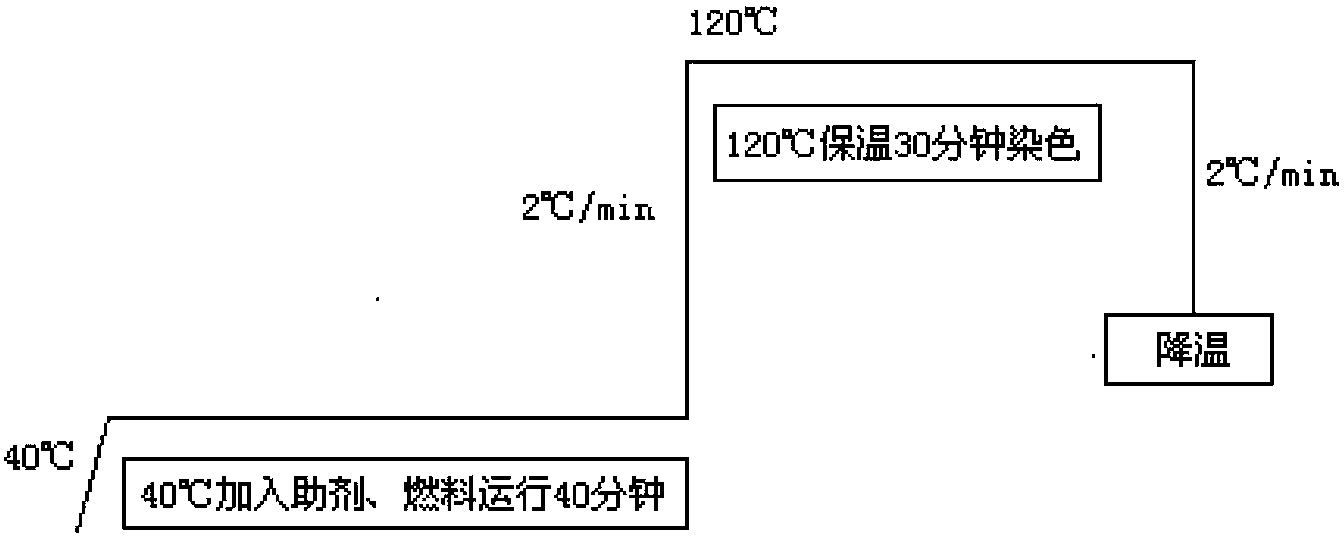

[0027] Such as figure 1 As shown, this embodiment provides a two-color effect fabric, including polybutylene terephthalate fiber and polyethylene terephthalate fiber, and the polybutylene terephthalate fiber and polyethylene terephthalate fiber The ethylene phthalate fibers are interwoven, and the interwoven polybutylene terephthalate fibers and polyethylene terephthalate fibers are printed and dyed by a piece dyeing method.

[0028] Step 1: Preparation of raw materials: polybutylene terephthalate, yarn count 75D / 48F, fiber content 50%; polyethylene terephthalate, yarn count 75D / 48F water-absorbing and quick-drying yarn.

[0029] Step 2: Weaving on the machine: choose a large circular machine with a machine size of 28G to weave, so that the tension on the polybutylene terephthalate machine is 5 grams. Adopt positive yarn feeding method, select the appropriate pattern through different yarn weaving ways, and the weight of the finished fabric is 160g / m 2 about.

[0030] Step...

Embodiment 2

[0037] Such as figure 1 As shown, this embodiment provides a two-color effect fabric, including polybutylene terephthalate fiber and polyethylene terephthalate fiber, and the polybutylene terephthalate fiber and polyethylene terephthalate fiber The ethylene phthalate fibers are interwoven, and the interwoven polybutylene terephthalate fibers and polyethylene terephthalate fibers are printed and dyed by a piece dyeing method.

[0038] Step 1: Preparation of raw materials: polybutylene terephthalate, yarn count 75D / 48F, fiber content 50%; polyethylene terephthalate, yarn count 75D / 48F water-absorbing and quick-drying yarn.

[0039] Step 2: Weaving on the machine: choose a large circular machine with a machine size of 28G to weave, so that the tension on the polybutylene terephthalate machine is 5 grams. The active yarn feeding method is adopted, and the appropriate pattern is selected through different yarn weaving ways. The weight of the finished fabric is about 160g / m2.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com