Large bidirectional dynamic/static direct-shearing machine for coarse-grained soil contact interface tests

A technology of contact interface and coarse-grained soil, which is applied in the direction of testing the strength of materials by applying a stable shear force, which can solve the problems of large shear path deviation, single shear direction, and inability to achieve bidirectionality at the same time, and achieve convenient control. , The effect of timely data transmission and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

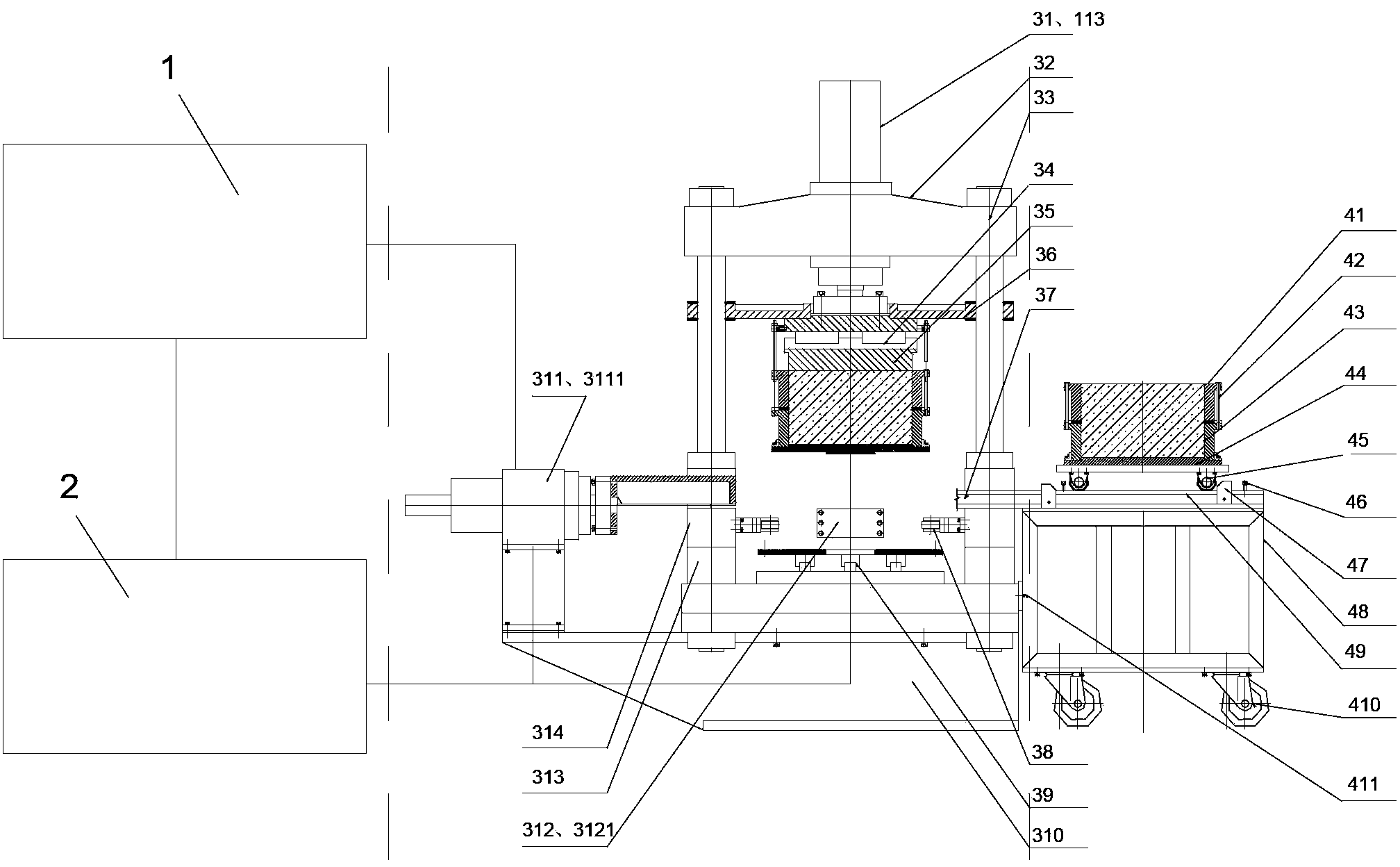

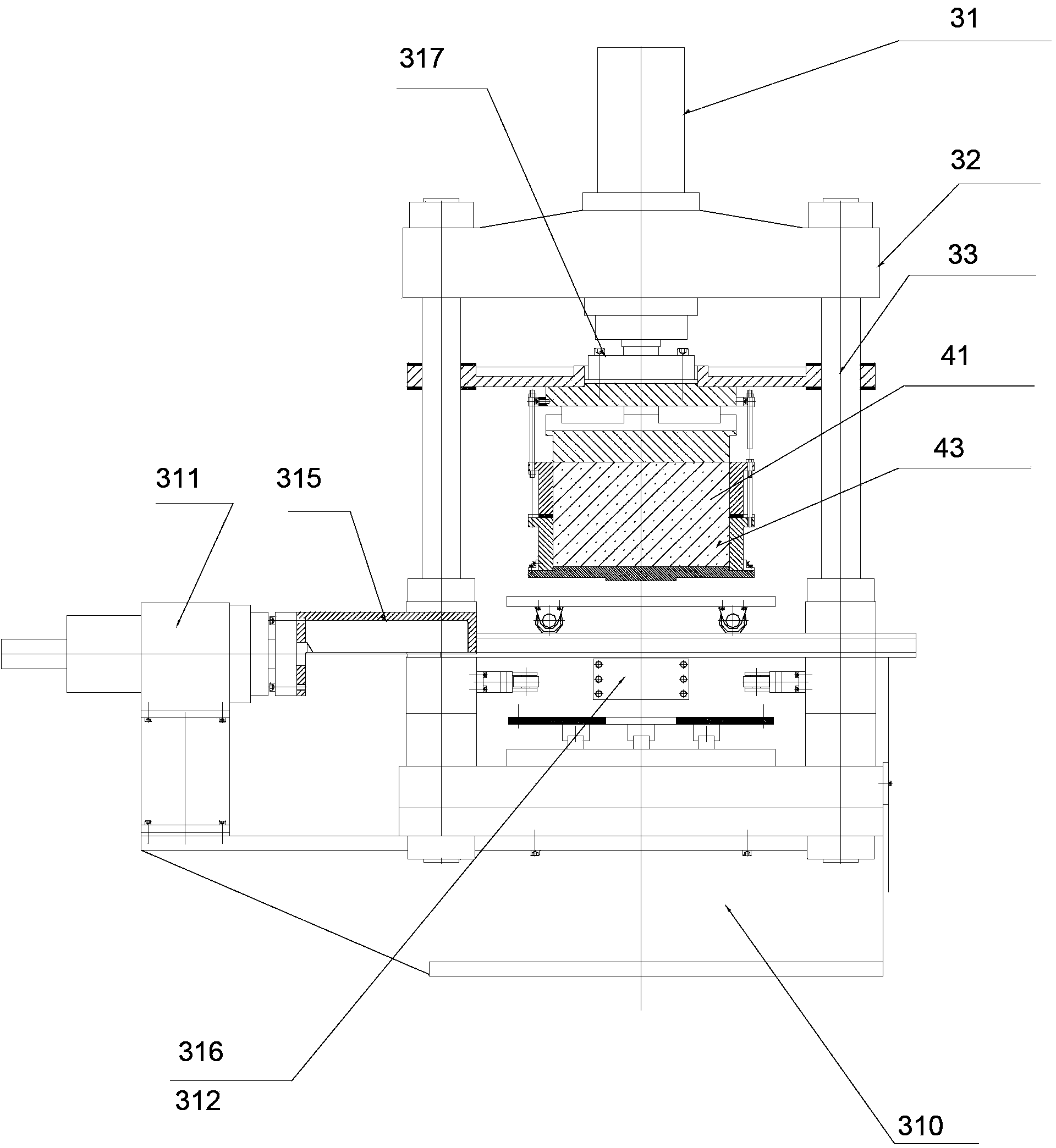

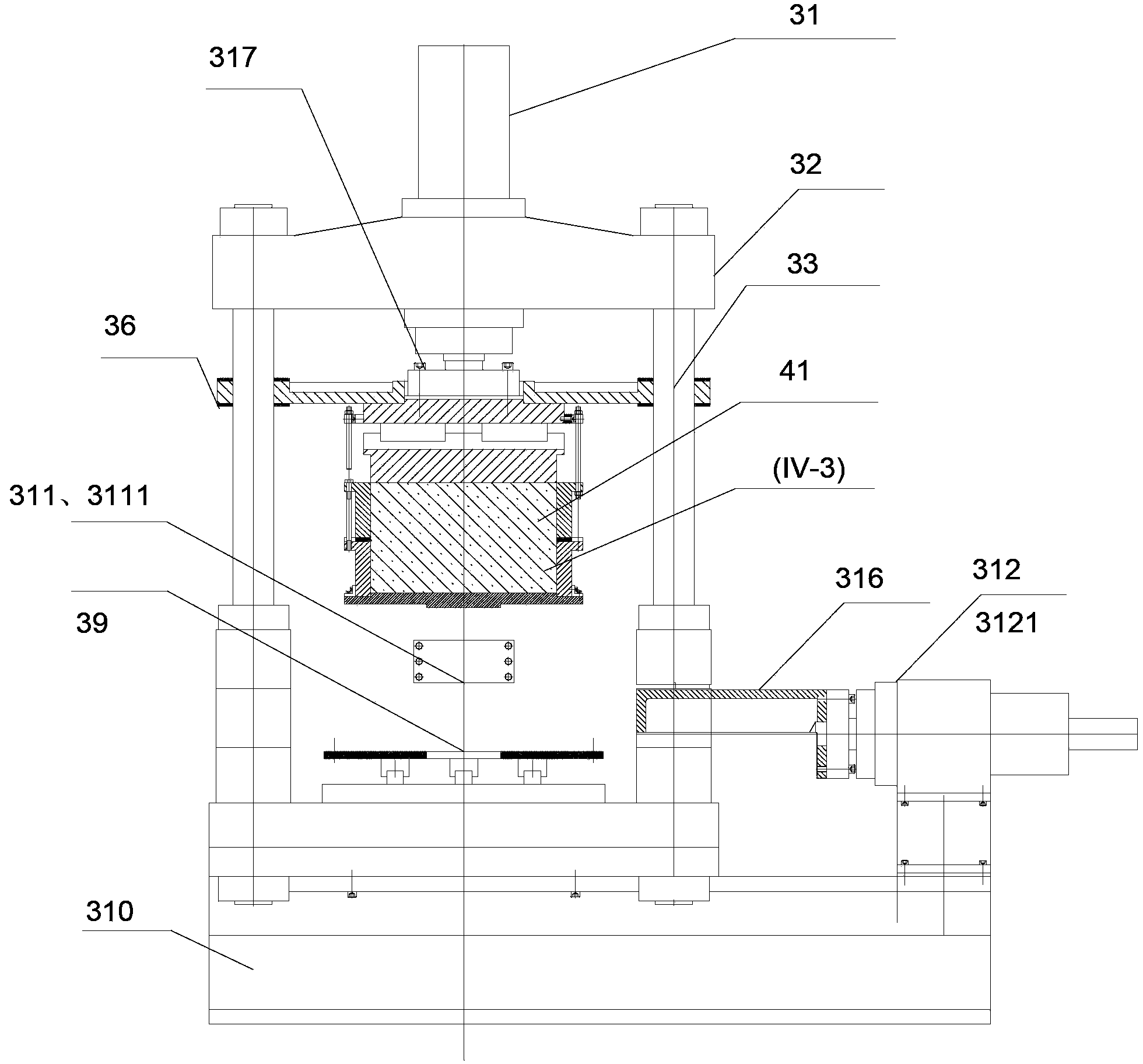

[0029] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5The large-scale two-way dynamic and static direct shear testing machine for the contact interface of coarse-grained soil provided by the present invention is composed of a measurement and control unit 1, a hydraulic servo unit 2, a loading unit 3, and a soil sample making unit 4. The loading unit 3 includes mutually perpendicular One Z-direction vertical loading frame, one X-direction horizontal loading frame and one Y-direction horizontal loading frame for loading capacity, the lower sliding guide rail 39 is provided on the load frame frame 310, and the lower sliding guide rail 39 is slid to be provided with the lower sliding guide rail connecting plate 318, the structure of the Z-direction vertical loading frame is: a loading frame column 33 is provided on the load frame frame 310, a loading frame bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com