Sensor-carrying device for plane guided wave online detection of defects of storage tank base plate

A storage tank bottom plate and sensor technology, which is applied in the field of ultrasonic measurement and pipeline system, can solve the problems of low detection efficiency, unfavorable technology application and promotion, and increased labor intensity of inspection personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

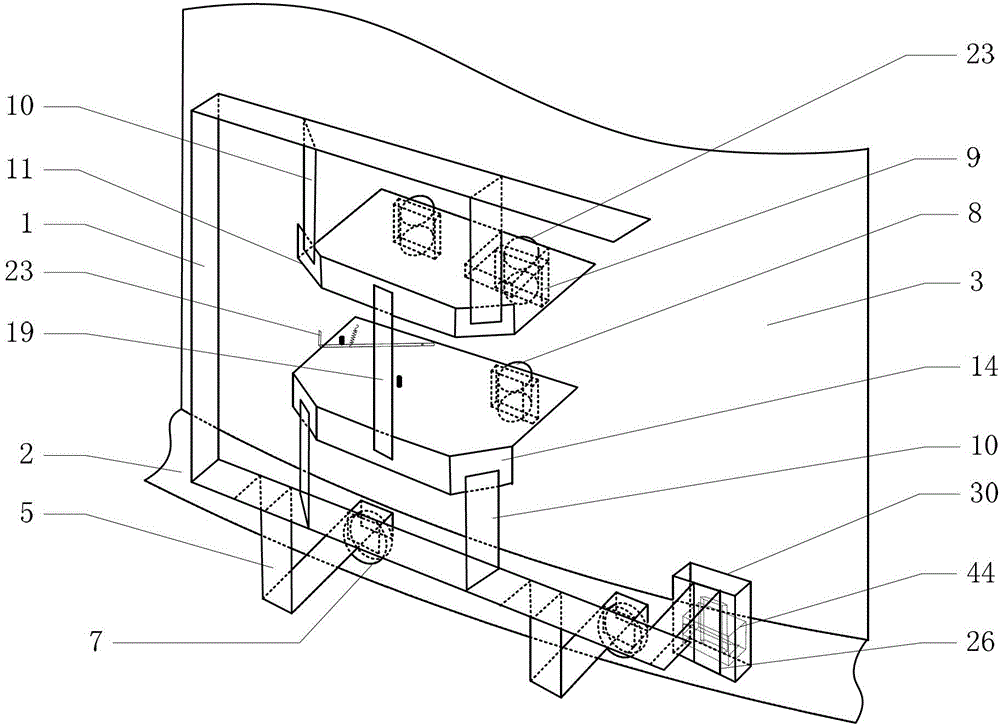

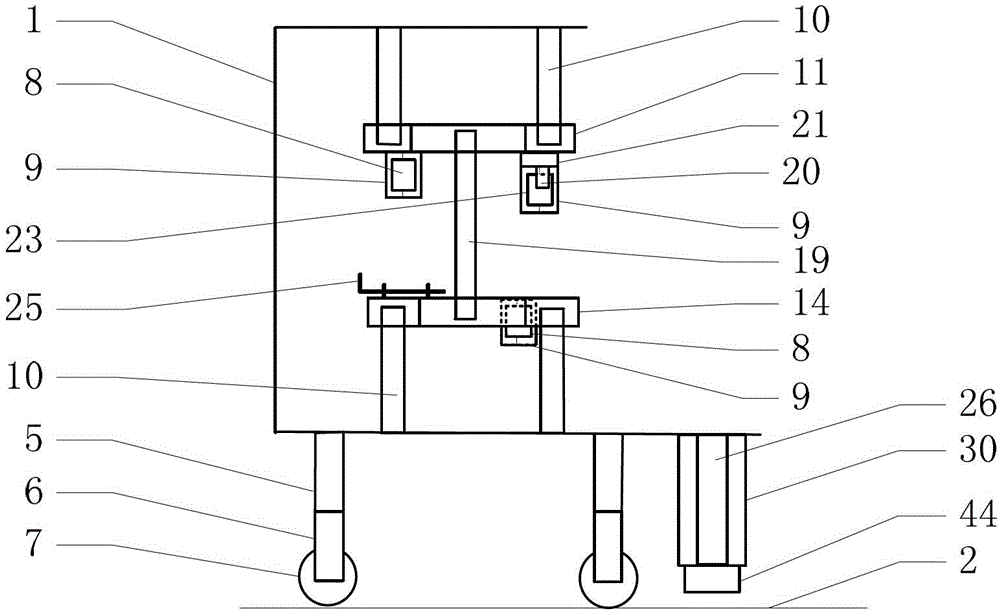

[0077] The materials of the device outer frame 1, support mechanism, adsorption mechanism, movement mechanism, removal mechanism, and sensor fixing mechanism of this example are all processed by high-strength aluminum alloy materials unless otherwise specified.

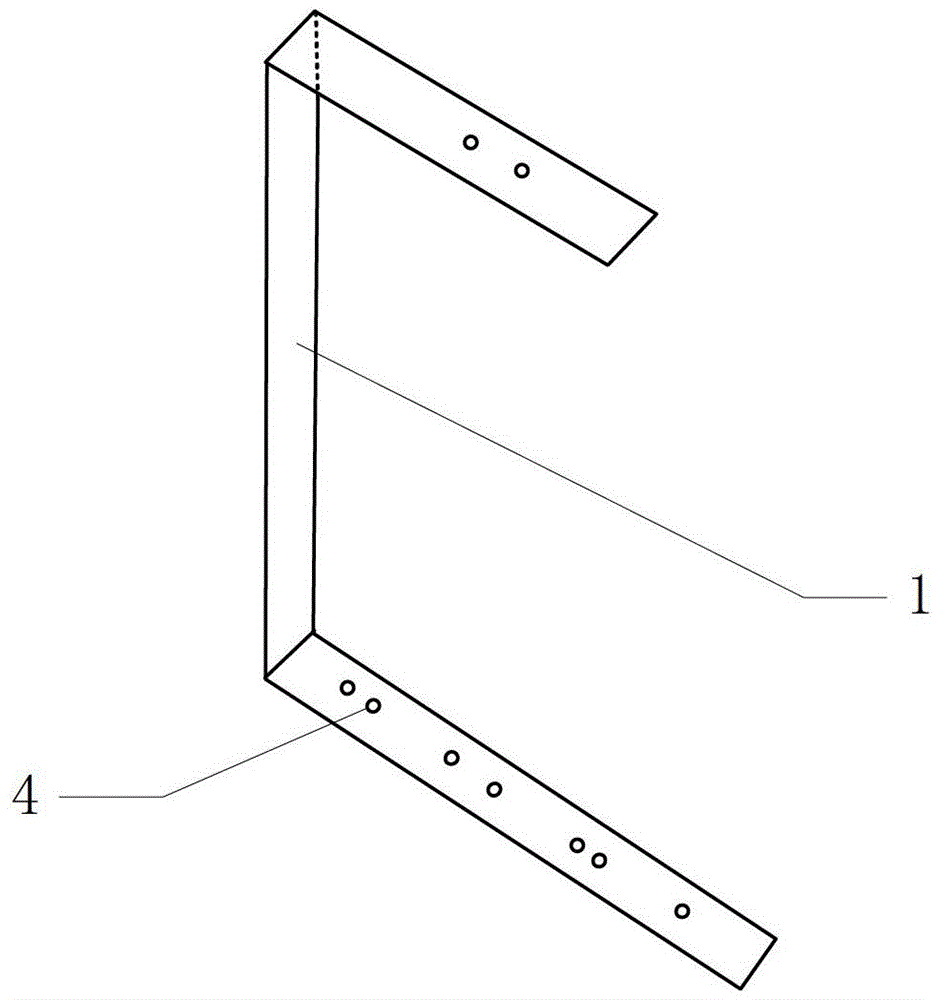

[0078] The outer frame 1 is a semi-"I"-shaped plate with a thickness of 3mm and a width of 40mm. The upper part of the half-"I" shape is 300mm long, and the lower section of the half "I" shape is 400mm long and 400mm high. The lower part of the half "I" shape has an assembly hole a4 The diameter is 5mm, and there are 9 assembly holes a4 in total, 2 in the upper part of the half "I" shape, and 7 in the lower part of the half "I" shape. The spacing of each assembly hole is determined according to the assembly hole spacing of the fixed mechanism.

[0079] The "Z"-shaped connector 5 of the support mechanism has a thickness of 2 mm and a width of 30 mm. The upper section of the "Z" shape is 40 mm long, the lower section is ...

Embodiment 2

[0090] This embodiment is basically the same as Embodiment 1, except for the following differences: 1) The thickness of the sensor cavity 44 is increased to 4mm, and other dimensions remain unchanged. The sensor cavity 44 does not use elastic rubber to fill the gap when accommodating sensors of different sizes, but installs adjusting bolts on the top, left side, right side and front side of the sensor container 44, and adjusts by screwing in and out of these bolts. The position of the sensor in the sensor cavity 44, and the fixing of the sensor is realized; 2) The "Z" shaped connector 5 in the support mechanism is fixed with the outer frame 1 through a single assembly hole a4 by bolts, and due to the single assembly hole, Therefore, the direction adjustment of the support wheel can be realized to meet the detection needs of storage tanks with different diameters and outer edge plate widths.

[0091] The two cases have been tested and found to be simple in structure, convenient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com