A mixed flat yarn and round yarn feeding system for warp knitting machines

A warp knitting machine and flat yarn technology, which is applied in the direction of flat warp knitting machine, warp knitting, filament/thread forming, etc., can solve the problem of complex ratio of polyolefin film materials and production process, restrictions on industrial production and promotion, Occupying a large space and other problems, to avoid special flat wire warping equipment and complicated flat wire warping process, shorten the length of the production line, and shorten the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

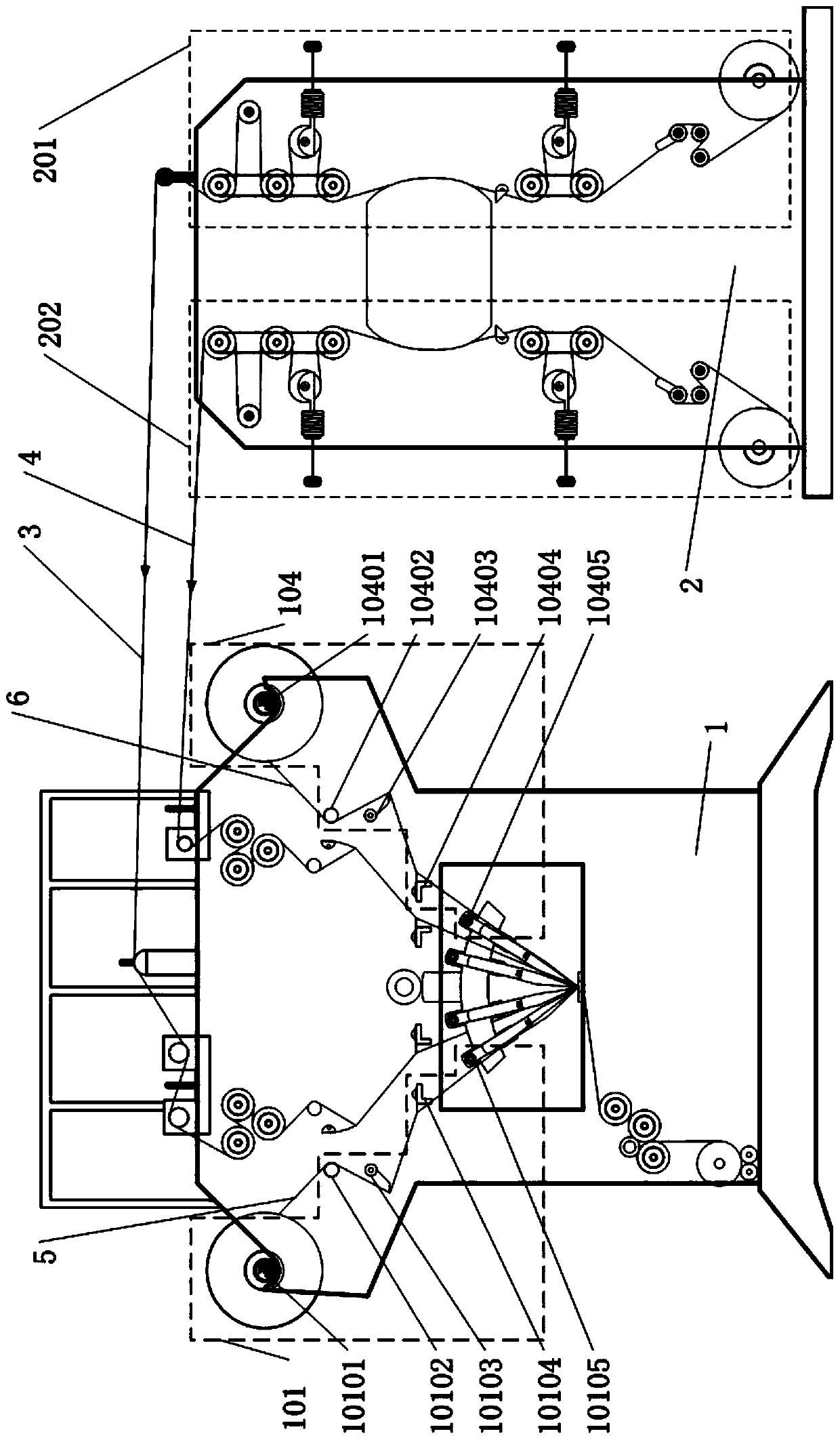

[0045] This embodiment provides a mixed yarn supply system for warp knitting machines with flat and round yarns, see figure 1 ;

[0046] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

[0047] like figure 1 As shown, a flat yarn and round yarn mixed yarn supply system for a warp knitting machine is composed of two major components: the main weaving part 1 of the warp knitting machine and the flat yarn supplying production part 2;

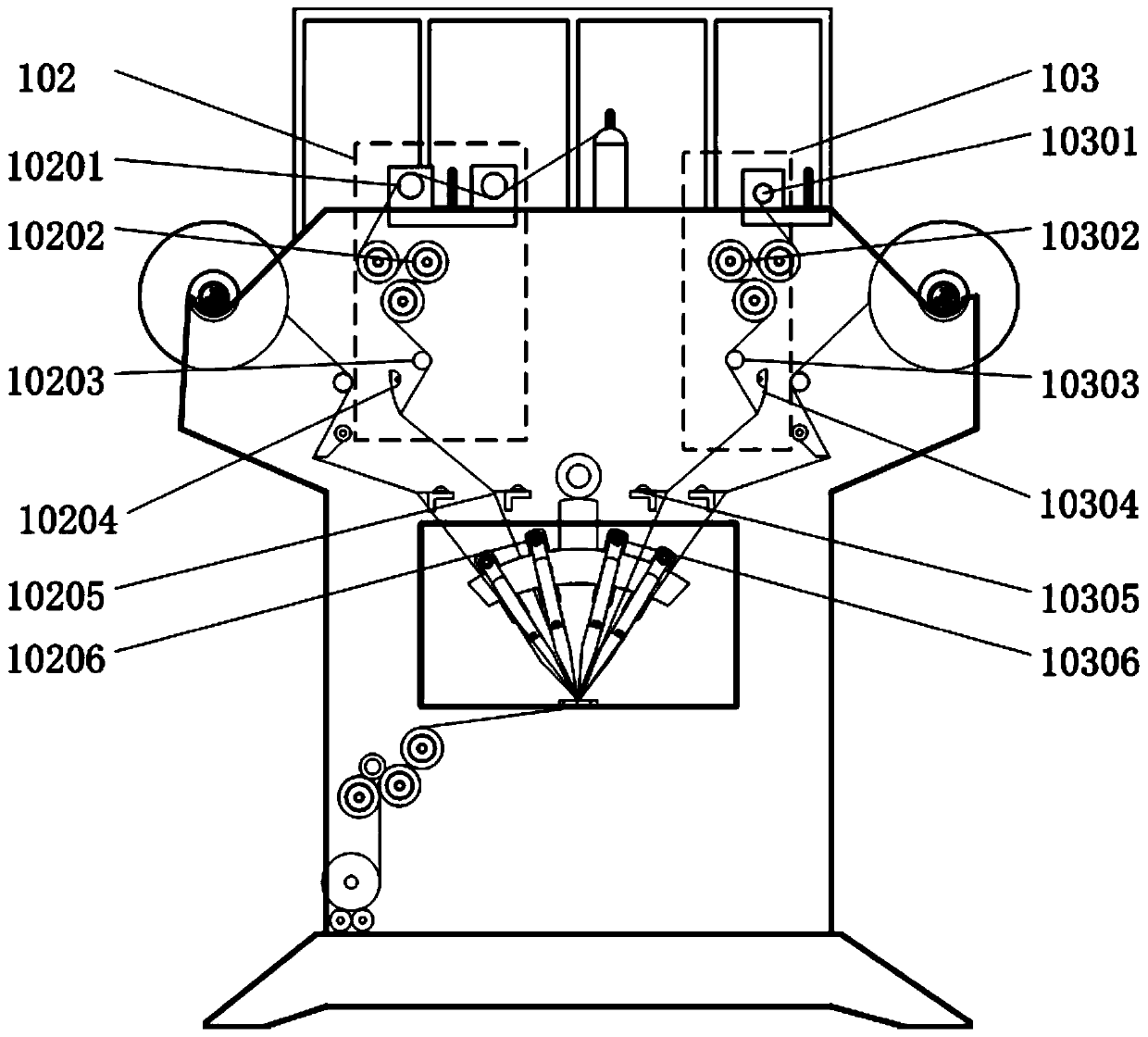

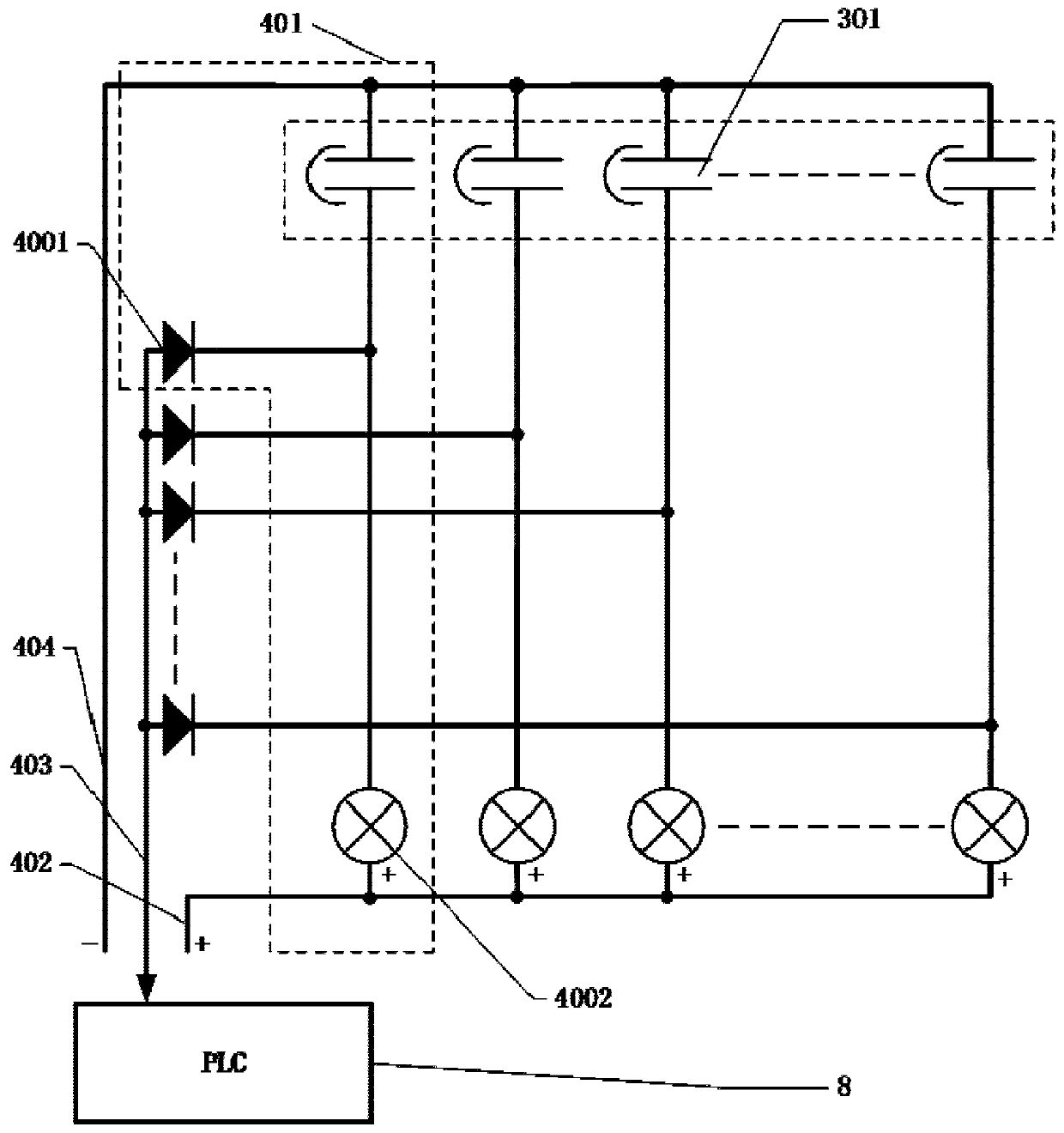

[0048] The main knitting part 1 of the warp knitting machine includes a warp round yarn feeding system 101, a warp flat yarn feeding system 102, a weft flat yarn feeding system 103, and a weft round yarn feeding system 104, a total of four yarn feeding systems;

[0049] The flat yarn supply production unit 2 includes a warp yarn fla...

Embodiment 2

[0060] This embodiment provides a mixed yarn supply system for flat yarn and round yarn for warp knitting machines, see figure 1 ;

[0061] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

[0062] like figure 1 As shown, a flat yarn and round yarn mixed yarn supply system for a warp knitting machine is composed of two major components: the main weaving part 1 of the warp knitting machine and the flat yarn supplying production part 2;

[0063] The main knitting part 1 of the warp knitting machine includes a warp round yarn feeding system 101, a warp flat yarn feeding system 102, a weft flat yarn feeding system 103, and a weft round yarn feeding system 104, a total of four yarn feeding systems;

[0064] The flat yarn supply production unit 2 includes a warp yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com