Yarn Break Detection System for Flat Yarn Warp Knitting Machine

A technology for yarn breakage detection and warp knitting machine, which is applied in textiles, papermaking, knitting and other directions to achieve the effects of simple detection method, improved system integration and reliability, and strong application pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings.

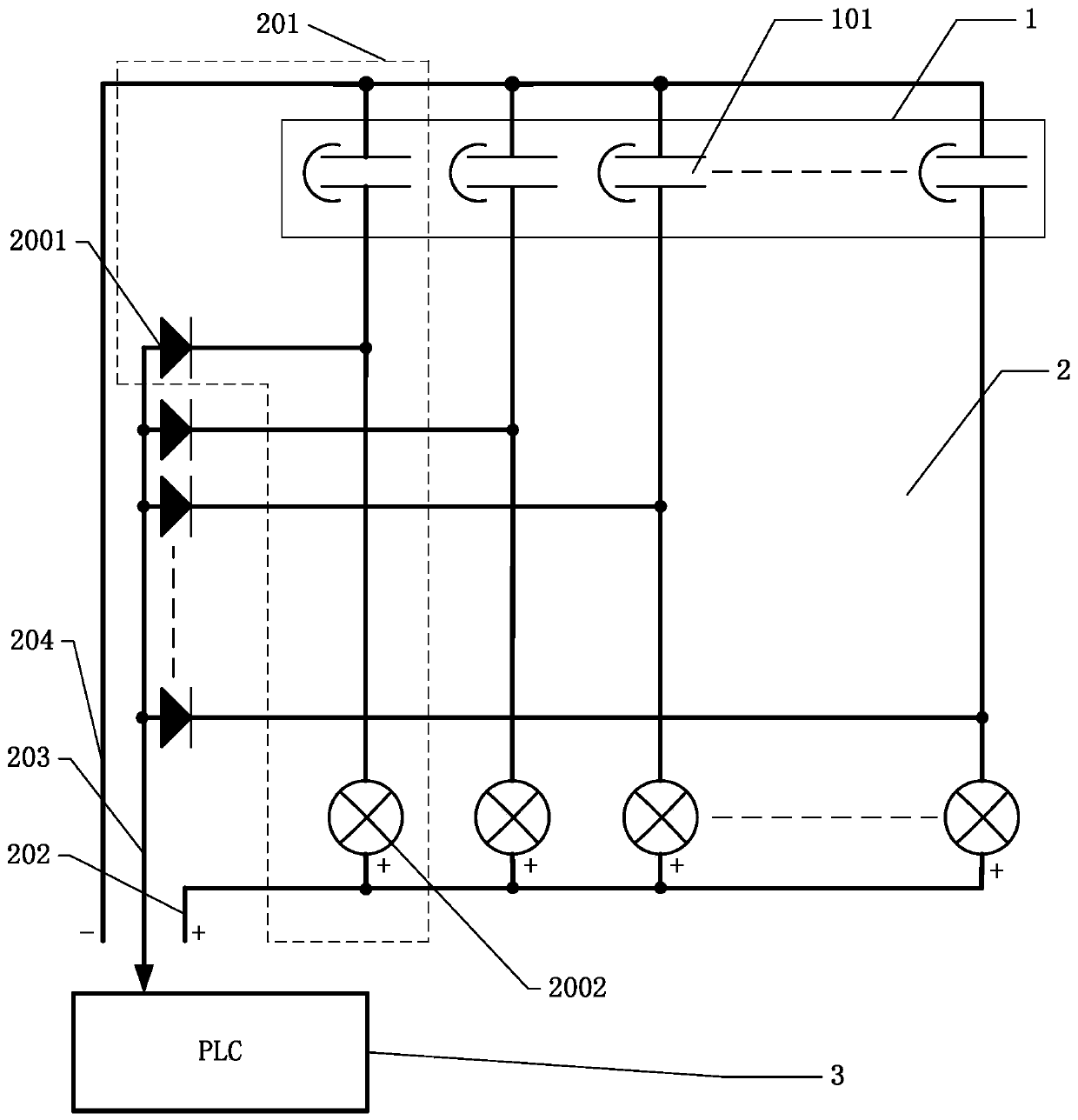

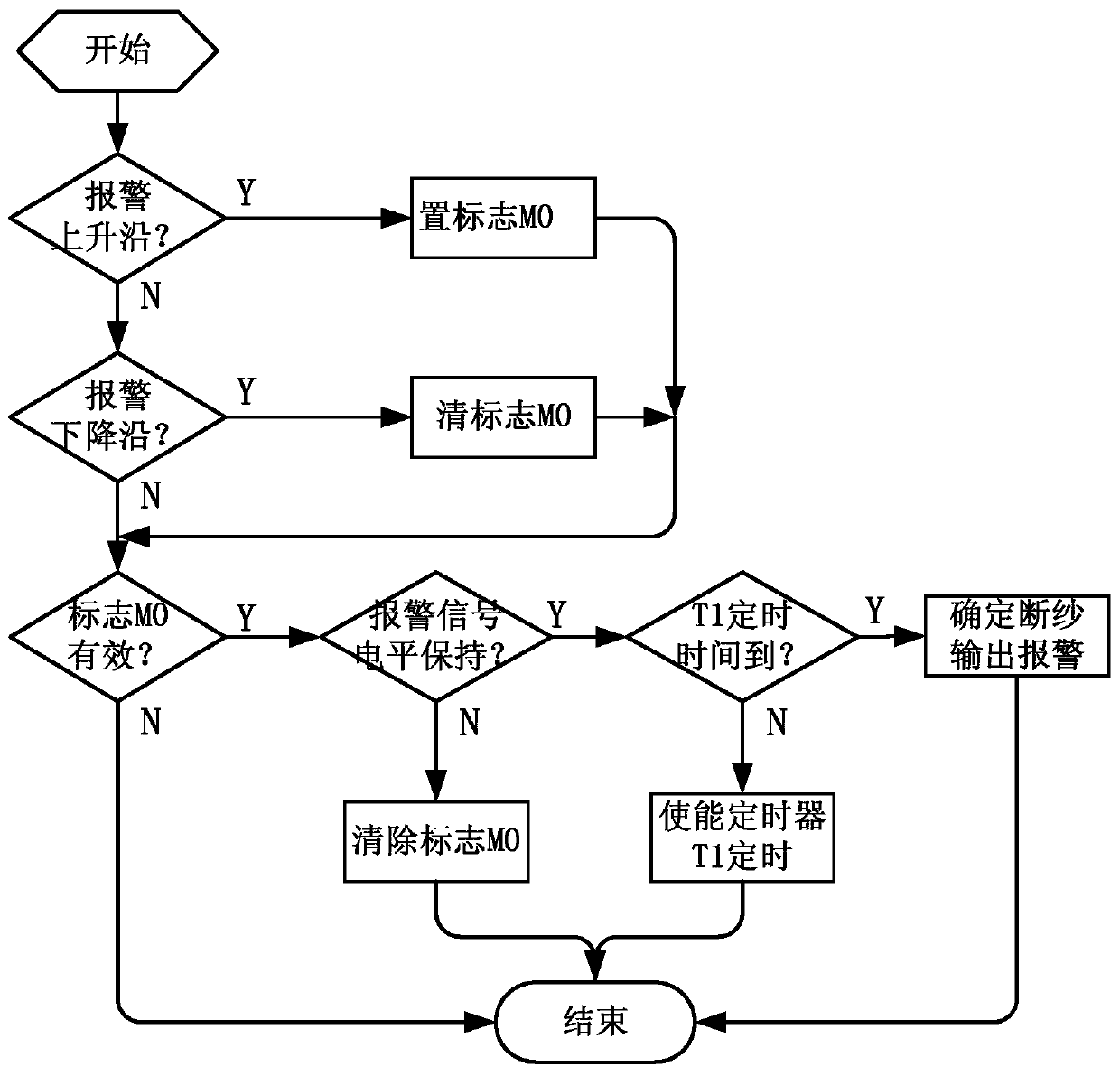

[0019] The implementation purpose of the present invention is based on the principle of contact-type broken yarn detection, using the unidirectional conductivity of the diode, and the segmented yarn broken detection frame structure to logically partition the broken yarn in different areas on the same yarn road, thereby realizing Regional alarm location indication for yarn broken alarm within the entire width range; in addition, the programmable logic software of the PLC controller is used to perform flexible fault-tolerant processing on the hardware circuit, and the variable-length timing filtering of the yarn broken alarm signal is used to realize false detection Avoidance of false alarms.

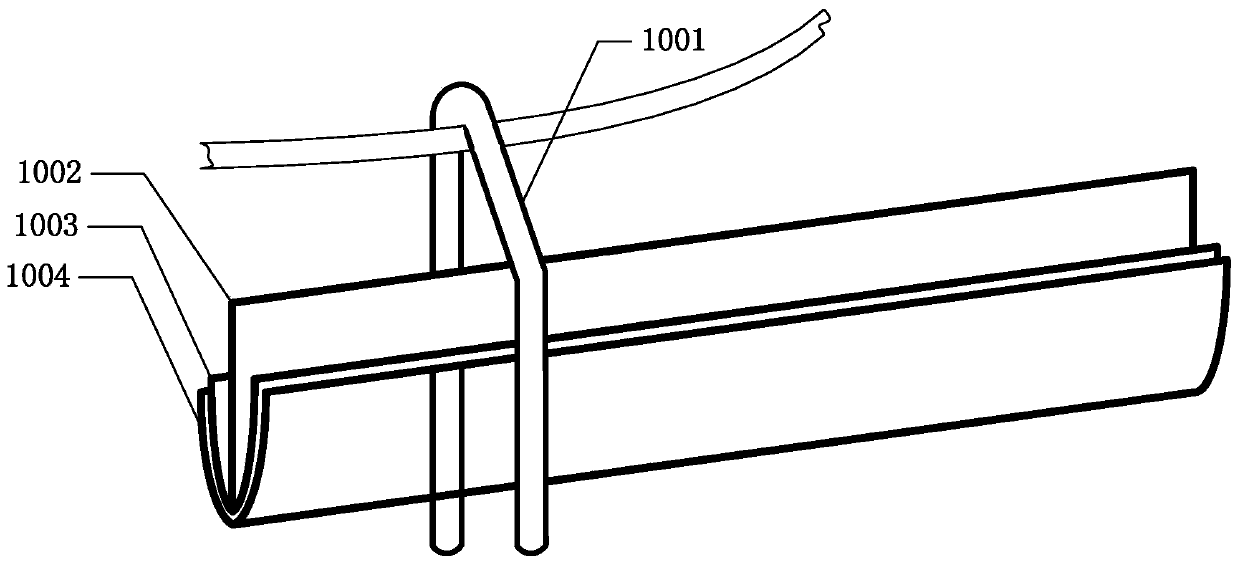

[0020] Such as figure 1 As shown, the broken yarn detection system for a flat yarn warp knitting machine of the present invention includes three main parts: a yarn broken detection frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com