Disc type motor rotor

A disc motor and rotor technology, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of poor motor performance and easy damage of permanent magnets, and achieves easy process, low price, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

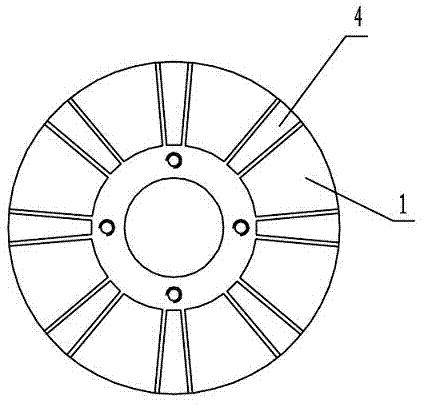

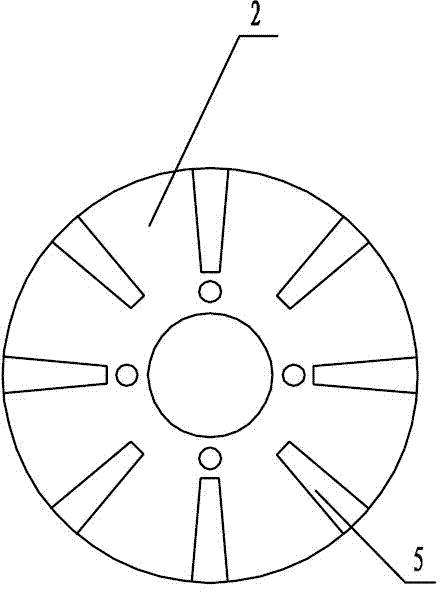

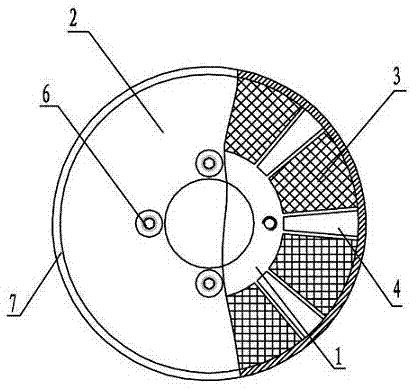

[0022] Embodiment: a kind of disc motor rotor, its structural diagram is as follows Figure 1 to Figure 3 As shown, it includes rotor cover plate 2, rotor iron core 1, permanent magnet 3 and sheath 7. There are four first screw holes in the center of the rotor iron core, and four first screw holes are also arranged on the rotor cover plate to match the first screw holes. The rotor cover plate and the rotor iron core are fixedly connected by screws 6 passing through the first screw hole and the second screw hole. It is fixedly connected with the side wall of the rotor cover and the side wall of the rotor core. The side wall of the rotor iron core is provided with 8 magnetic steel slots for embedding permanent magnets, the magnetic steel slots are evenly distributed on the side wall of the rotor iron core, and the permanent magnets are embedded in the magnetic steel slots and fixedly connected with the rotor iron core. The permanent magnet is in the shape of a fan-shaped ring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com