Press section of a machine for producing a fibrous web and method for producing a fibrous web

A press section, fiber web technology, applied in the press section, paper machine, papermaking, etc., can solve the problems of poor web running, tearing, unusable, etc., achieve low felt cost, improve dehydration, and save driving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

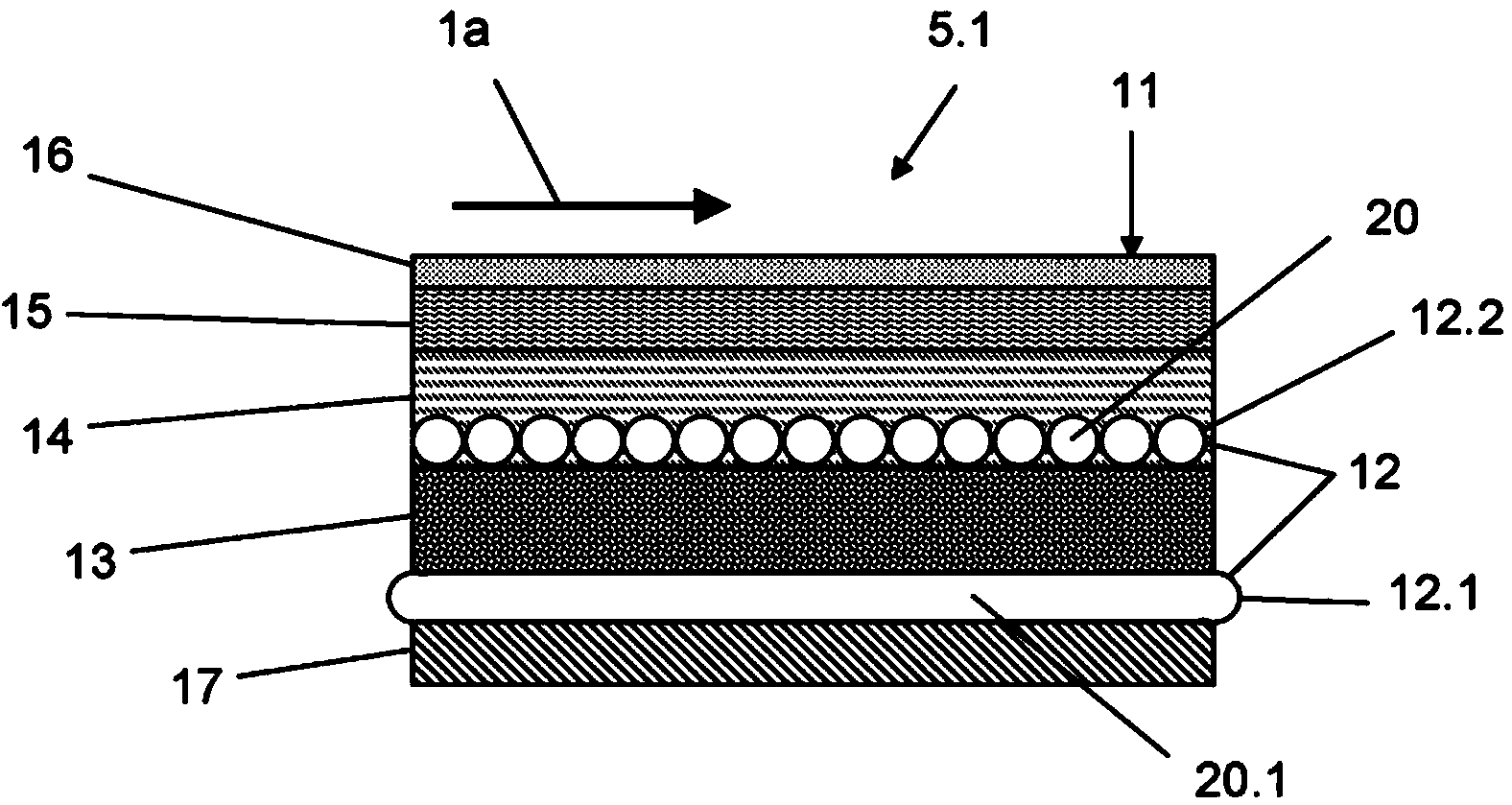

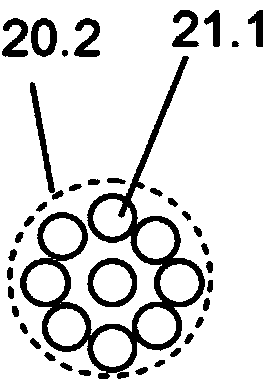

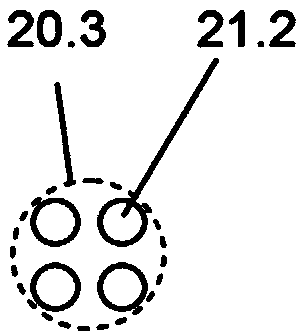

[0032] figure 1 The structure of a possible felt 5.1 is shown in cross section. The basic structure 12 here consists of two layers 12.1 and 12.2, wherein in one layer, namely layer 12.1, the threads are oriented in the web running direction 1a and wherein in this case both layers consist of monofilament threads (20 and 20.1) form. The scrim layer 13 is arranged as an intermediate layer between the substructure layers. In this case, the scrim layer 12 can consist of one or more layers. Generally, the weight of the thick non-woven fabric layer 13 is at 100g / m 2 up to 600g / m 2 between. The two further nonwoven layers 14 , 15 and the fine nonwoven layer 16 are located on the side facing the fiber web. A nonwoven layer 17 is applied to the running side of the felt. This combination achieves very good dewatering over the entire running time of the felt. So-called fused fibers can be contained in the nonwoven layers 14 , 15 , 17 and / or in the scrim layer 13 , which serve to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com