Naturally circulated heat removal method and system for slurry-bed reactor of Fische-Tropsch synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

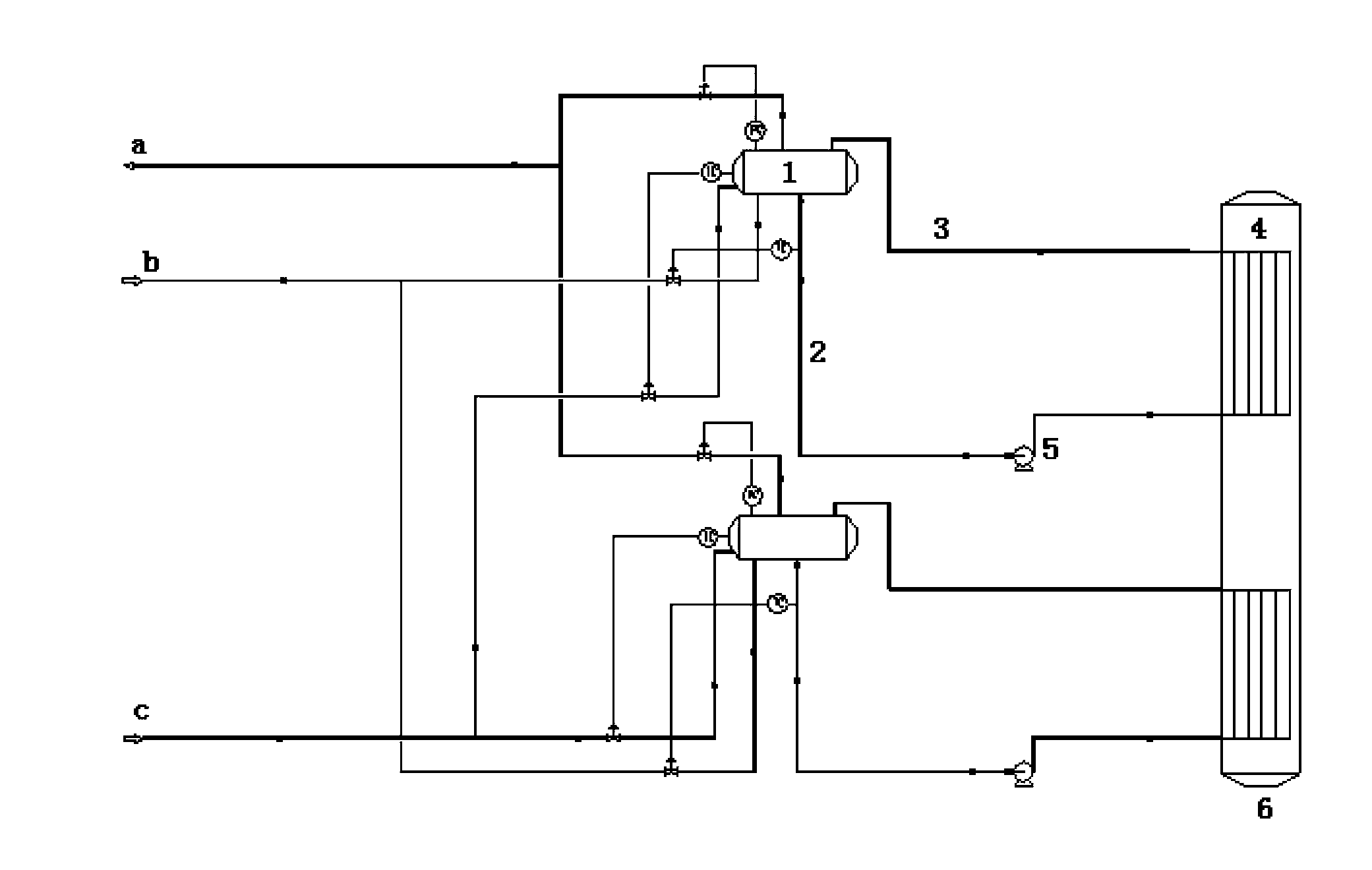

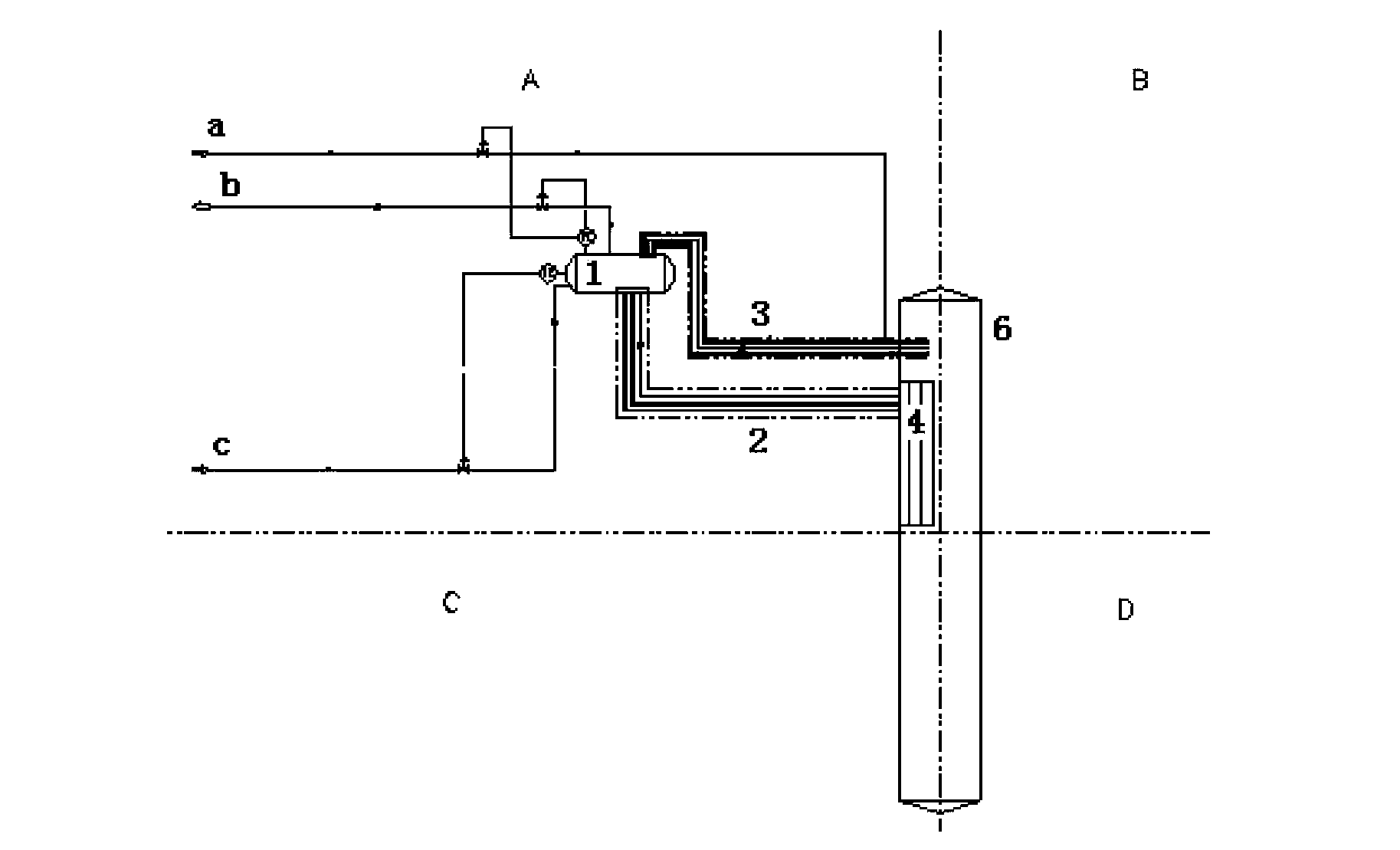

[0053] The Fischer-Tropsch synthesis reaction device is equipped with 2 reactors, and the reaction heat of each reactor is ~330MW. The slurry bed temperature in the reactor: normal temperature is 255°C, the highest temperature is 270°C, and can generate 2.9MPa saturated steam ~510t / h . If the original forced circulation scheme is used, at least 6 hot water circulation units need to be installed, and the power consumption of the pumps is about 1.5MW. To reduce energy consumption, natural circulation methods are used. The specific plan is:

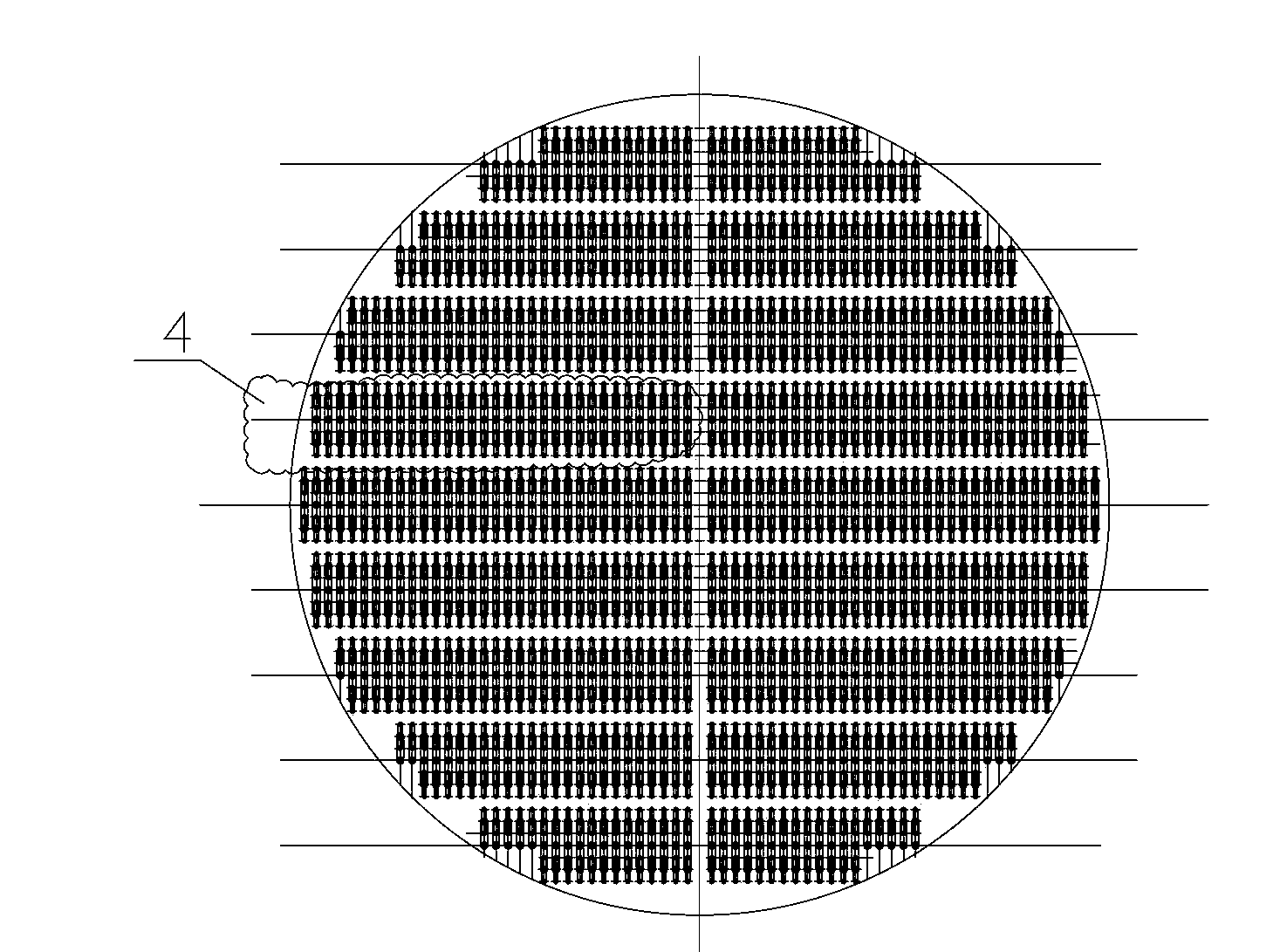

[0054] According to the process design requirements, installation conditions and the water cycle calculation results of similar projects, the reactor is divided into four sections for heat extraction: the upper left part, the lower left part, the upper right part, and the lower right part, and each part forms its own system. , each system consists of a steam drum, centralized downcomer, centralized riser, and heat extraction elements, of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com