A kind of preparation method of gamma-alumina

A technology of alumina and inorganic aluminum salts, which is applied in the direction of alumina/aluminum hydroxide, can solve problems that need to be further developed, and achieve the effects of product stability, low reaction temperature, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

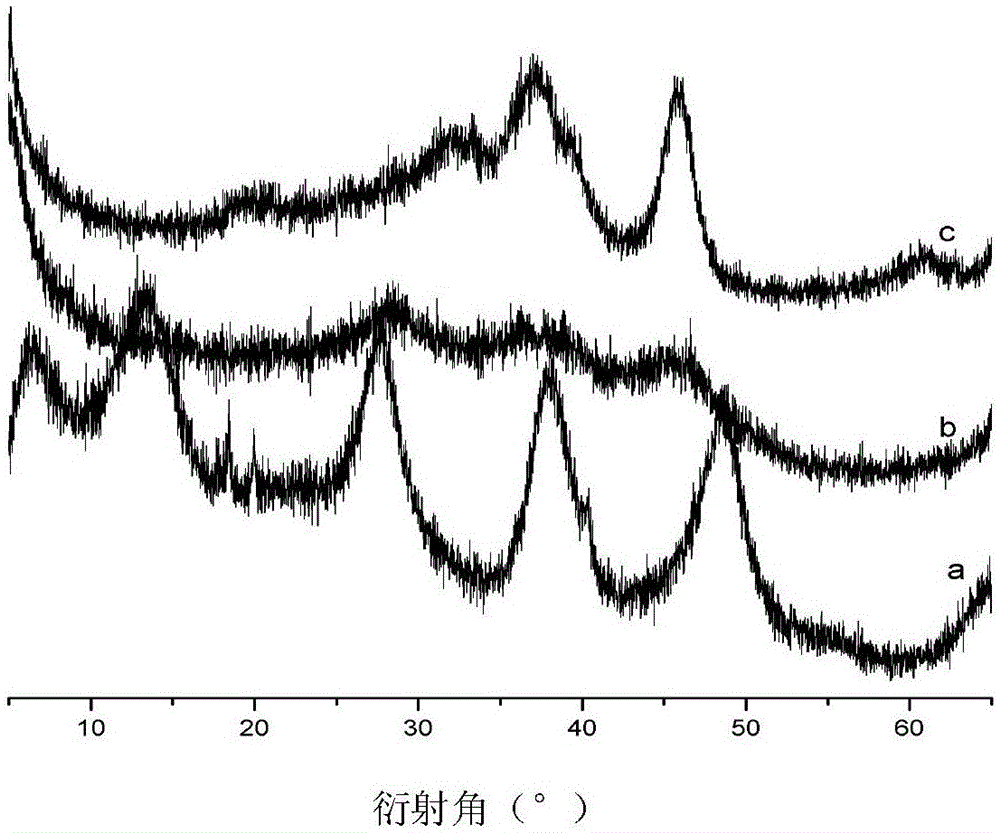

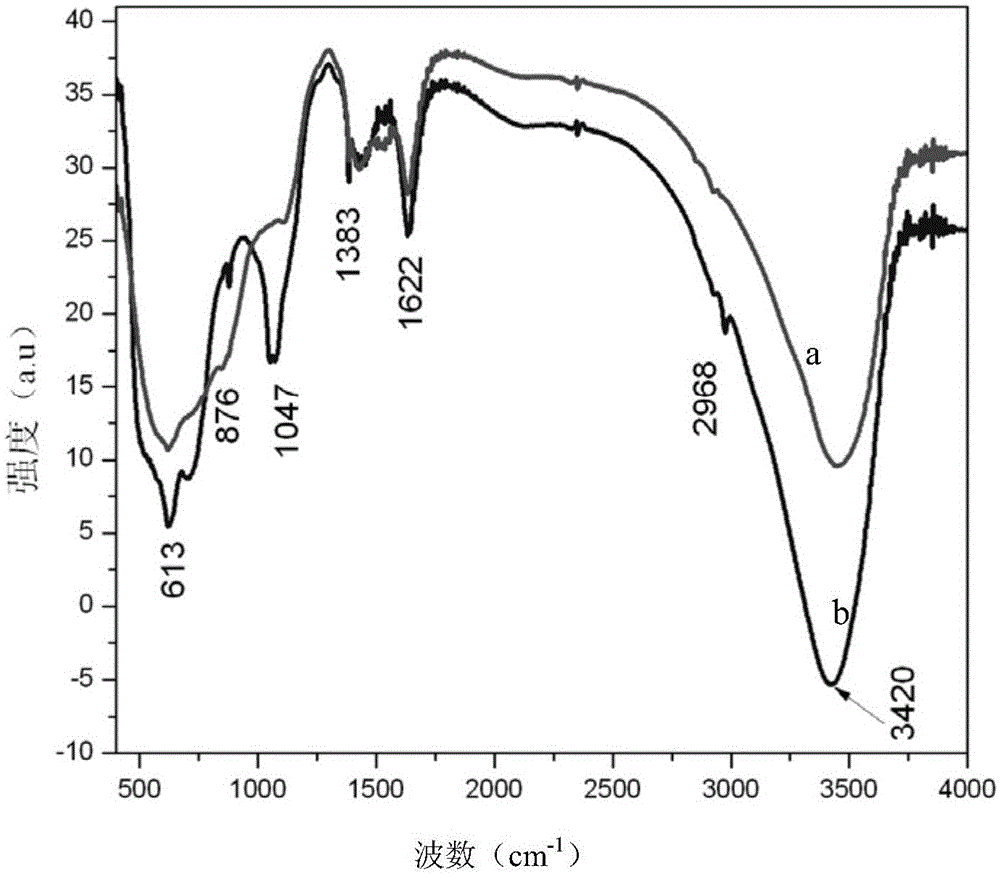

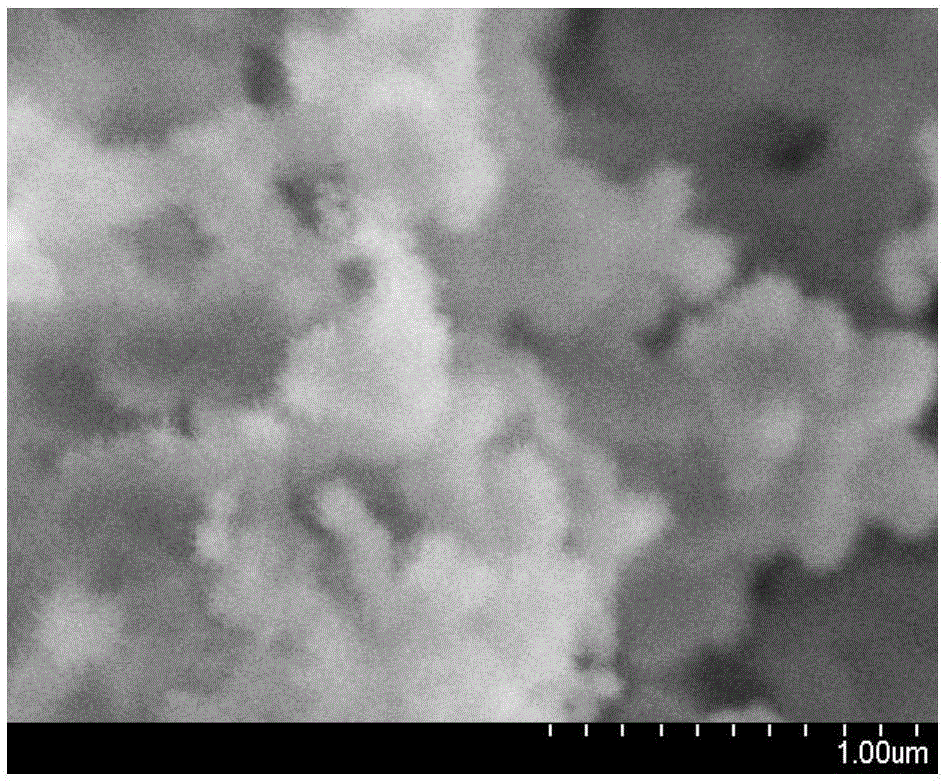

Image

Examples

Embodiment 1

[0024] Drugs: sodium metaaluminate (Sinopharm Chemical Reagent Co., Ltd., AR, purity ≥ 41.0%), absolute ethanol (Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (Xiamen Linde Gas Co., Ltd., purity ≥ 99.99%) .

[0025] The first step: prepare ethanol aqueous solution, the ratio of alcohol to water is 1:1 (volume ratio), accurately weigh 1.02g of sodium metaaluminate and place it in a 50ml volumetric flask, add an appropriate amount of ethanol aqueous solution, and prepare 0.25M metaaluminate sodium ethanol in water. Pour the solution into a 180ml reaction kettle, seal it, place it in a water bath, and heat the water bath to 60°C.

[0026] The second step: the CO 2 Pour into the reactor, preheat the CO at the inlet of the reactor 2 , through the pressure control valve to adjust the CO 2 The pressure is 8 MPa, and the temperature and pressure are maintained for 30 minutes to react to obtain hydrated alumina which is the precursor of γ-alumina.

[0027] The third st...

Embodiment 2

[0032] Drugs: sodium metaaluminate (Sinopharm Chemical Reagent Co., Ltd., AR, purity ≥ 41.0%), absolute ethanol (Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (Xiamen Linde Gas Co., Ltd., purity ≥ 99.99%) .

[0033] This example adopts the same process and equipment as in Example 1, except that the ratio of alcohol to water is 2:1.

[0034] The specific surface area, pore volume and pore diameter of γ-alumina obtained at 400°C are 405.3m 2 / g, 1.1cm 3 / g and 9.3nm. After calcination at 800°C for 2 hours, the specific surface area, pore volume and pore diameter of γ-alumina are 347.4m 2 / g, 0.73cm 3 / g and 13.5nm.

Embodiment 3

[0036] Drugs: sodium metaaluminate (Sinopharm Chemical Reagent Co., Ltd., AR, purity ≥ 41.0%), absolute ethanol (Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (Xiamen Linde Gas Co., Ltd., purity ≥ 99.99%) .

[0037] This example adopts the same process and equipment as in Example 1, except that the ratio of alcohol to water is 3:1.

[0038] The specific surface area, pore volume and pore diameter of the γ-alumina obtained at 400°C are 306.9m 2 / g, 0.95cm 3 / g and 15.7nm. After calcination at 800°C for 2 hours, the specific surface area, pore volume and pore diameter of γ-alumina are 181.3m 2 / g, 0.95cm 3 / g and 18.1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com