Synthesis method of tetrahydropyrazolone derivative

A technology of tetrahydropyrazolone and synthesis method, which is applied in the field of synthesis of tetrahydropyrazolone derivatives, can solve the problems of high price, difficult to store, environmental pollution, etc., achieves high yield and product purity, is convenient for storage and Transportation, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

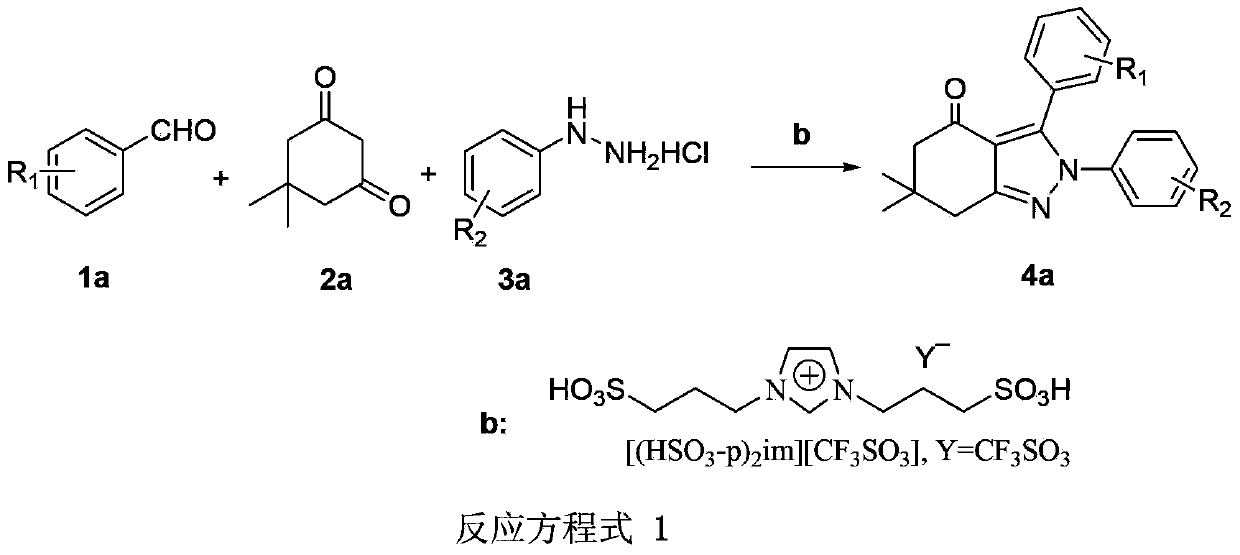

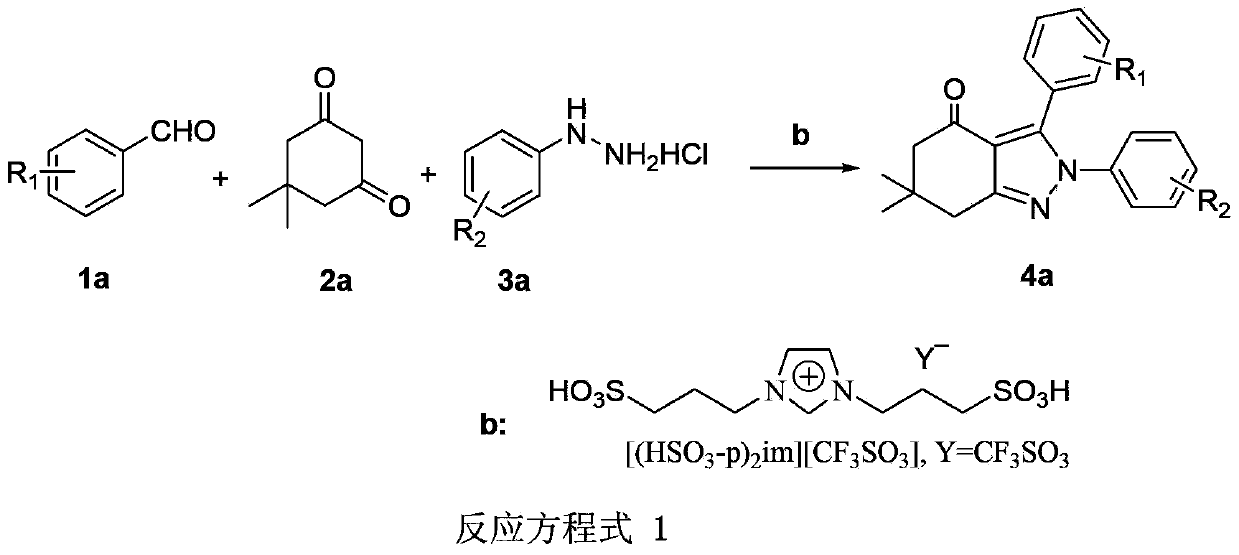

Method used

Image

Examples

Embodiment 1

[0022]

[0023] Add benzaldehyde (25mmol), 5,5-dimethylcyclohexanedione (25mmol), phenylhydrazine hydrochloride (25mmol), ionic liquid (0.125mmol), and absolute ethanol 10mL into the reaction vessel in sequence , put the reaction vessel in a microwave reactor, microwave reaction at 80°C for 20 minutes (ultrasonic input power 400W), after the reaction, distill off ethanol, wash the remaining solid with 20mL water, filter, and recrystallize the filter cake with ethanol to obtain the product , yield 85%.

[0024] Characterization data: 1 H NMR (400MHz, DMSO-d 6 ):δ=7.50(s,1H),7.38–7.31(m,6H),7.18–7.25(m,2H),6.94(d,J=8.0Hz,1H),2.82(s,2H),2.43( s,2H),1.17(s,6H); 13 C NMR (100MHz, CDCl 3 ): δ28.47, 34.85, 53.73, 105.01, 116.21, 124.19, 127.67, 129.85, 130.21, 130.27, 132.09, 133.13, 138.38, 143.46, 156.96, 193.38.

Embodiment 2

[0026]

[0027] Add p-tolualdehyde (25mmol), 5,5-dimethylcyclohexanedione (25mmol), phenylhydrazine hydrochloride (25mmol), ionic liquid (0.125mmol), and absolute ethanol 10mL to the In the reaction vessel, place the reaction vessel in a microwave reactor and react with microwaves at 80°C for 20 minutes (ultrasonic input power 400W). After the reaction, ethanol is distilled off, and the remaining solid is washed with 20mL of water, filtered, and the filter cake is weighed with ethanol. The product was crystallized with a yield of 87%.

[0028] Characterization data: 1 H NMR (400MHz, DMSO-d 6 ):δ=7.44–7.35(m,3H),7.35-7.28(m,2H),7.17(d,J=8.0Hz,2H),6.90(d,J=4.0Hz,2H),2.85(s, 2H),2.41(s,2H),2.23(s,3H),1.20(s,6H); 13 CNMR (100MHz, CDCl 3 ): δ19.75, 28.44, 34.87, 37.13, 53.70, 123.49, 126.01, 126.25, 128.71, 130.97, 131.68, 134.69, 135.70, 136.48, 137.68, 156.73, 193.55.

Embodiment 3

[0030]

[0031] Add p-chlorobenzaldehyde (25mmol), 5,5-dimethylcyclohexanedione (25mmol), phenylhydrazine hydrochloride (25mmol), ionic liquid (0.125mmol), and absolute ethanol 10mL to the reaction in sequence In the container, put the reaction container in a microwave reactor, microwave reaction at 80°C for 20 minutes (ultrasonic input power 400W), after the reaction, distill off ethanol, wash the remaining solid with 20mL water, filter, and recrystallize the filter cake with ethanol The product was obtained with a yield of 88%.

[0032] Characterization data: 1 H NMR (400MHz, DMSO-d 6 ):δ=7.50-7.43(m,2H),7.38–7.31(m,4H),7.18–7.25(m,2H),6.93(d,J=8.0Hz,1H),2.81(s,2H), 2.43(s,2H),1.18(s,6H); 13 C NMR (100MHz, CDCl 3 ): δ28.46, 34.86, 53.63, 105.05, 116.22, 125.19, 127.67, 129.87, 130.21, 130.27, 132.09, 133.13, 138.38, 144.46, 156.97, 193.38.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com