Continuous synthesis process of alpha-chloro-alpha-acetyl-gamma-butyrolactone

A synthesis process and acetyl technology, applied in the direction of organic chemistry, etc., can solve the problems of low utilization rate of chlorine gas, uneven distribution of chlorine gas, over temperature, etc., and achieve the effect of improving utilization rate of chlorine gas, avoiding excessive side reactions and continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

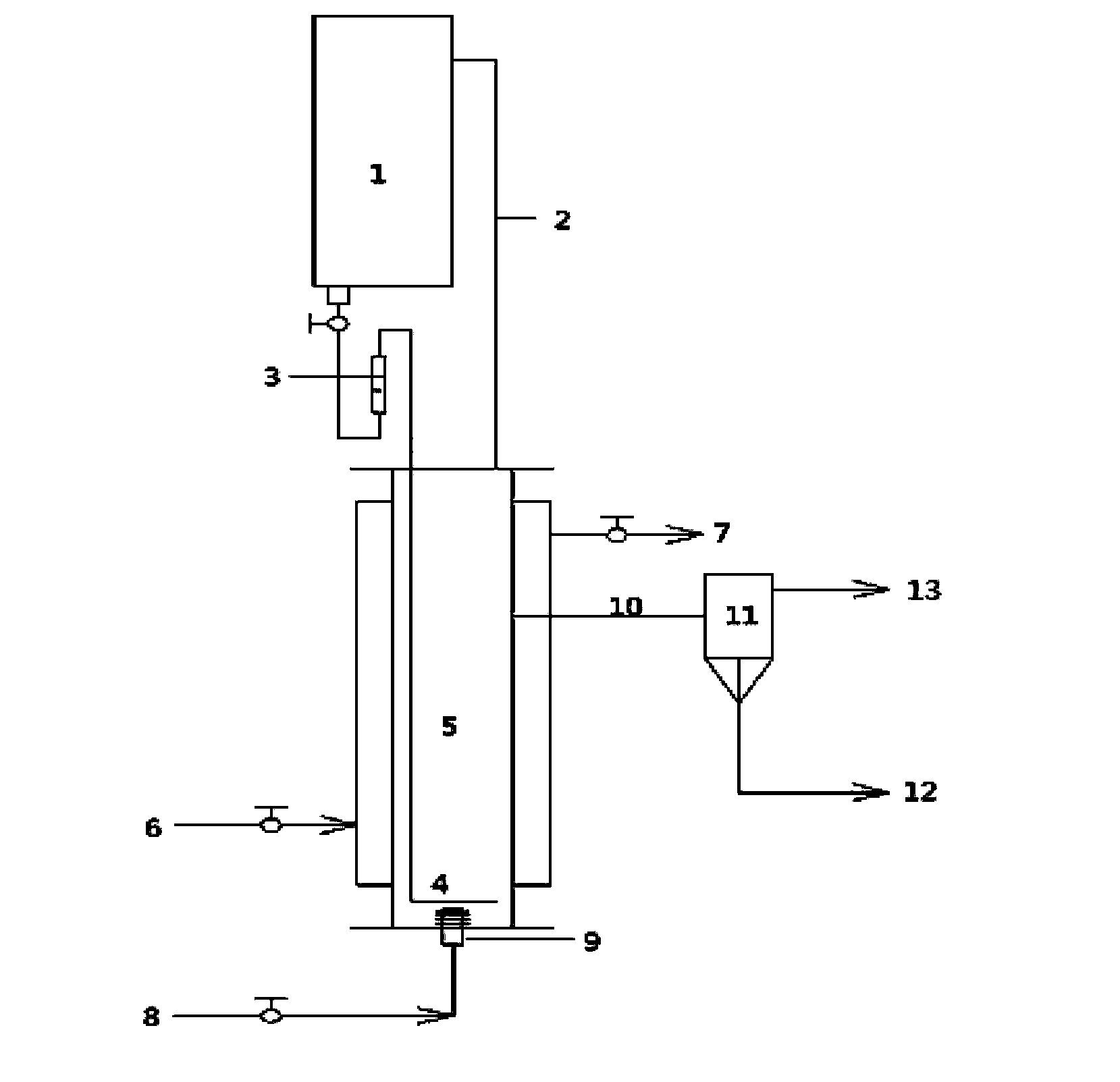

[0021] Add 100g of α-acetyl-γ-butyrolactone, 280g of water, and 65g of sodium bicarbonate into a 500ml round-bottomed flask, start stirring and mix thoroughly, pour the premixed liquid into the constant pressure premixed liquid addition funnel 1, and use a laminated glass Condenser (with an overflow opening at a moderate position) is used as reactor 5, and the bottom of reactor 5 is connected to the chlorine gas inlet, and the outlet of said premixed solution dropping funnel 1 is extended into the bottom of said reactor 5 after dripping flowmeter 3, After passing through the material distribution pipe 4, it enters into the reaction kettle 5, chlorine gas enters the reaction kettle 5 through the chlorine gas distribution head 9 after being metered through the chlorine gas inlet pipe 8, and the overflow liquid in the reaction kettle 5 enters through the discharge pipe 10. The stratifier 11 performs stratification, the upper water layer is extracted through the water layer pipe 13...

Embodiment 2

[0024] Add 280g of α-acetyl-γ-butyrolactone, 650g of water, and 185g of sodium bicarbonate into a 1000ml round bottom flask, start stirring and mix thoroughly, pour the premixed liquid into the constant pressure premixed liquid addition funnel 1, and use a laminated glass Condenser (with an overflow opening at a moderate position) is used as reactor 5, and the bottom of reactor 5 is connected to the chlorine gas inlet, and the outlet of said premixed solution dropping funnel 1 is extended into the bottom of said reactor 5 after dripping flowmeter 3, After passing through the material distribution pipe 4, it enters into the reaction kettle 5, chlorine gas enters the reaction kettle 5 through the chlorine gas distribution head 9 after being metered through the chlorine gas inlet pipe 8, and the overflow liquid in the reaction kettle 5 enters through the discharge pipe 10. The stratifier 11 performs stratification, the upper water layer is extracted through the water layer pipe 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com