Method for measuring metal aluminum content in garbage incineration slag

A technology of waste incineration slag and metal aluminum, which is applied in the field of solid waste resource utilization, can solve the problems of undiscovered metal aluminum content, influence on measurement accuracy, mutual interference, etc., achieve high reproducibility, and convenient and fast operation process , Determining the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 The method for measuring the metal aluminum content in the garbage incineration slag, fully dispersing the garbage incineration slag in saturated Ca(OH) 2 In the lye, the volume of hydrogen gas released is measured by the drainage method, and then the content of metal aluminum in the waste incineration slag is calculated. The Ca(OH) 2 For analytical purity. The waste incineration slag is added to Ca(OH) 2 Before being placed in the lye, it is ground to an average particle size of less than 80 microns.

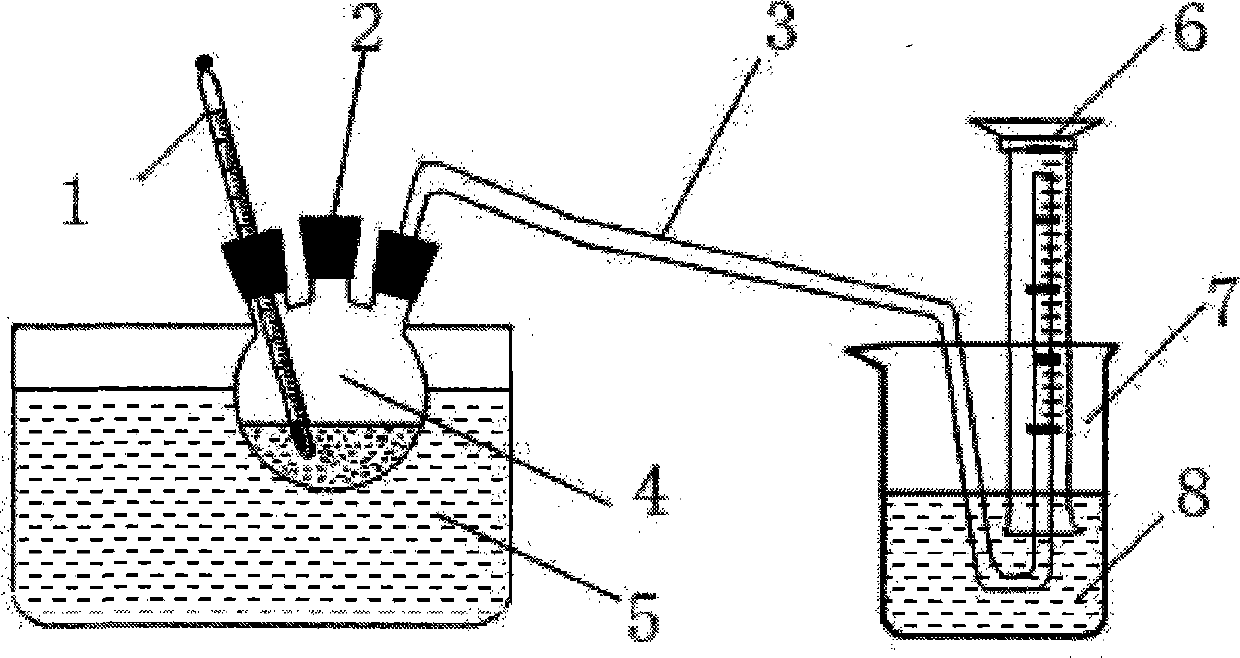

[0026] The volume of hydrogen gas is measured by the drainage method, see figure 1 shown. according to figure 1 Connect the device well, immerse the end of the outlet tube in water, then hold the flask with both hands, and observe whether there are any bubbles overflowing, if there are, it means that the airtightness is good, if not, you need to check carefully to ensure the airtightness of the device.

[0027] Before testing the amount of hydrogen gas...

Embodiment 2

[0029] Example 2 The method for measuring the aluminum content in waste incineration slag, the basic steps are the same as in Example 1, but the lye in the flask is heated to 70°C in a water bath, and the waste incineration slag obtained by wet discharge is used, and the waste incineration slag is baked at 105°C Dry processing.

Embodiment 3

[0030] Example 3 The method for determining the metal aluminum content in waste incineration slag, the basic steps are the same as in Example 1, but the lye in the flask is heated to 60° C. in a water bath. In this embodiment, the waste incineration slag has a large odor and residual wood, ceramic chips, iron materials and unburned plastics, etc., so it needs to be pretreated by deodorization, iron removal, screening, etc. before grinding , the pretreatment is the removal of wood, ceramic flakes and unburned plastics.

[0031] Principle of the present invention: garbage incineration slag contains a certain amount of metal aluminum components, metal aluminum and Ca(OH) 2 The solution reaction equation is as follows: Ca(OH) 2 +2Al+2H 2 O=Ca(AlO 2 ) 2 +3H 2 ↑. Under standard conditions, one mole of any ideal gas occupies a volume of about 22.4 liters. Therefore, as long as the volume of hydrogen gas produced can be accurately detected, the content of metallic aluminum can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com