Method for simulating DSG (Direct Steam Generation) trough heat collector by using nonlinear distributed parameter model

A technology of distributed parameter model and trough heat collector, which is applied in the fields of instruments, electrical digital data processing, special data processing applications, etc., can solve problems affecting the accuracy of dynamic characteristics and achieve good output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

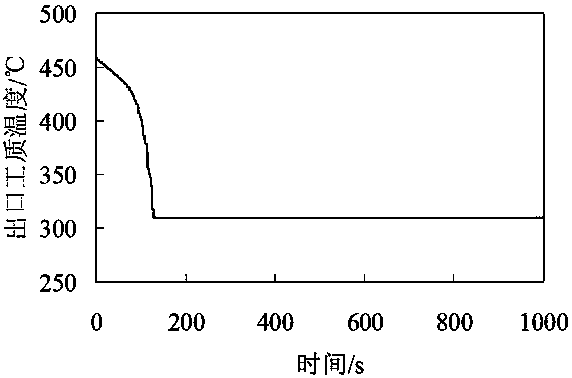

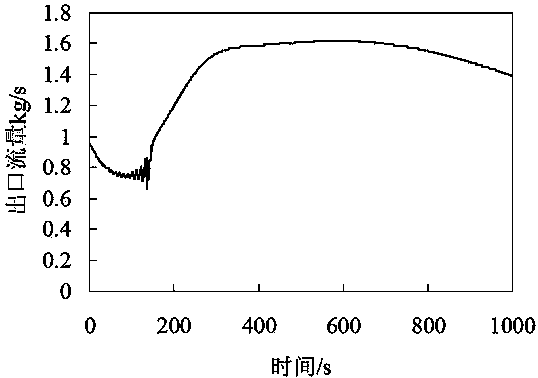

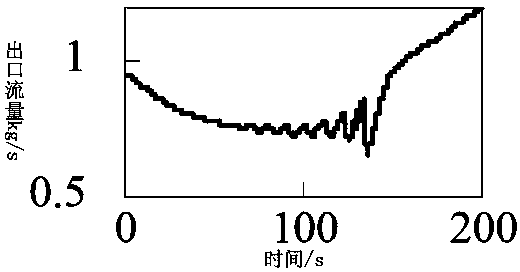

[0026] The solar radiation energy is reflected by the concentrator, acts on the surface of the metal tube wall through the glass seal tube and vacuum area of the heat-absorbing tube, and is transmitted inward through the metal tube wall; the working medium (water, water vapor or two-phase flow ) enters from the inlet of the heat-absorbing tube and undergoes convective heat exchange with the tube wall, and its thermodynamic parameters are constantly changing. Its simplified physical model Figure 5 shown. F is the cross-sectional area of the tube; T is the temperature of the working medium; H is the specific enthalpy of the working medium; D is the mass flow rate of the working medium; P is the pressure of the working medium; ω is the flow rate of the working medium; ρ is the density of the working medium; Q 1 , Q 2 are the heat release per unit time, unit tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com