Spicy shrimp seasoning and production method thereof

A production method and a technology for spicy shrimp are applied in the field of food condiments, which can solve the problems of single taste, inability to guarantee food safety, lack of layering, etc., and achieve the effects of enriching nutrition, improving food safety, and avoiding the use of preservatives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

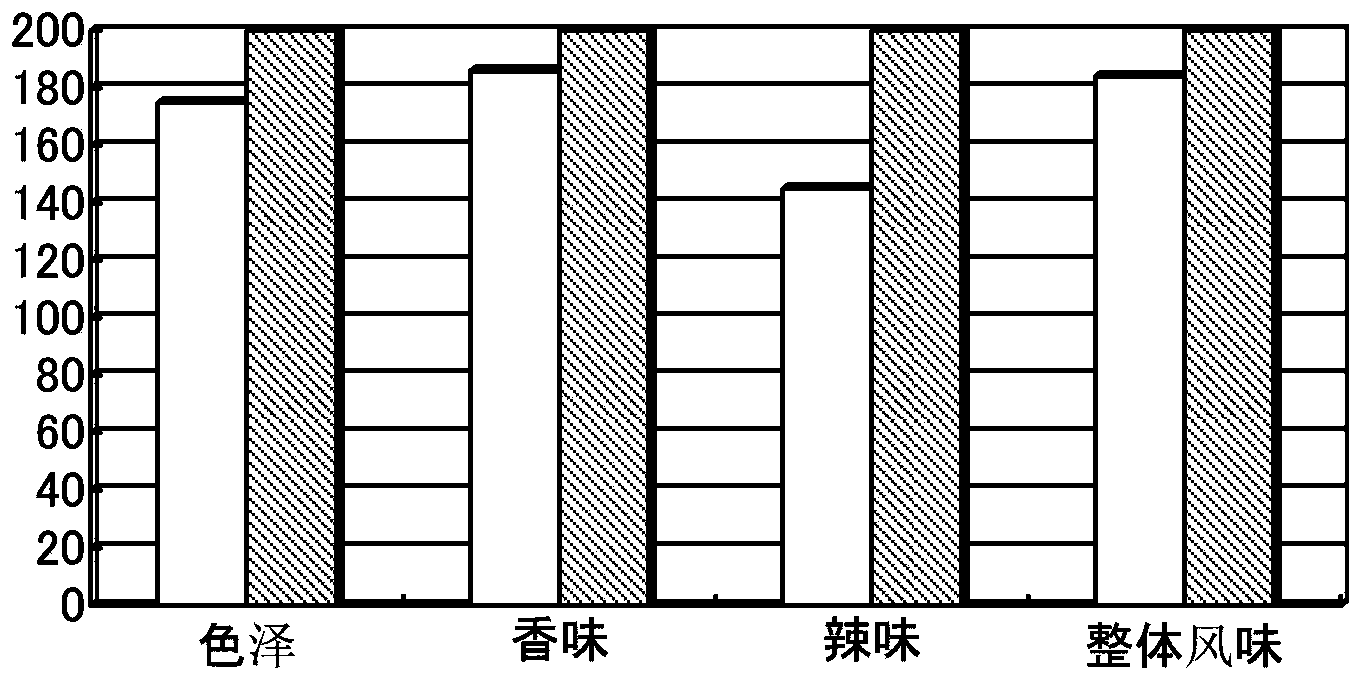

Image

Examples

Embodiment 1

[0057] Embodiment 1, making the spicy shrimp seasoning of the present invention

[0058] 1. Formula (mass percentage)

[0059] 26% rapeseed oil, 18.5% Pixian watercress, 12% dried chili powder, 1.5% tempeh, 1% ginger, 1% pickled ginger, 5.5% garlic, 0.5% pickled pepper, 3.95% compound spices, 1% green pepper powder, 12% edible salt, 3% monosodium glutamate, 0.1% white wine, 3.5% rice wine, 0.05% 5'-taste nucleotide disodium, 0.3% Yeast extract, 0.45% food flavor, 0.5% brewed soy sauce, 0.03% tea polyphenols and 1.5% white sugar.

[0060] Compound spices: 0.3% star anise, 0.1% cumin, 0.05% cardamom, 0.05% bay leaf, 0.3% grass fruit, 1.2% sesame, 0.3% pepper, 0.1% clove, 0.05% coriander However, it can be used after crushing, using a ¢1mm sieve to crush.

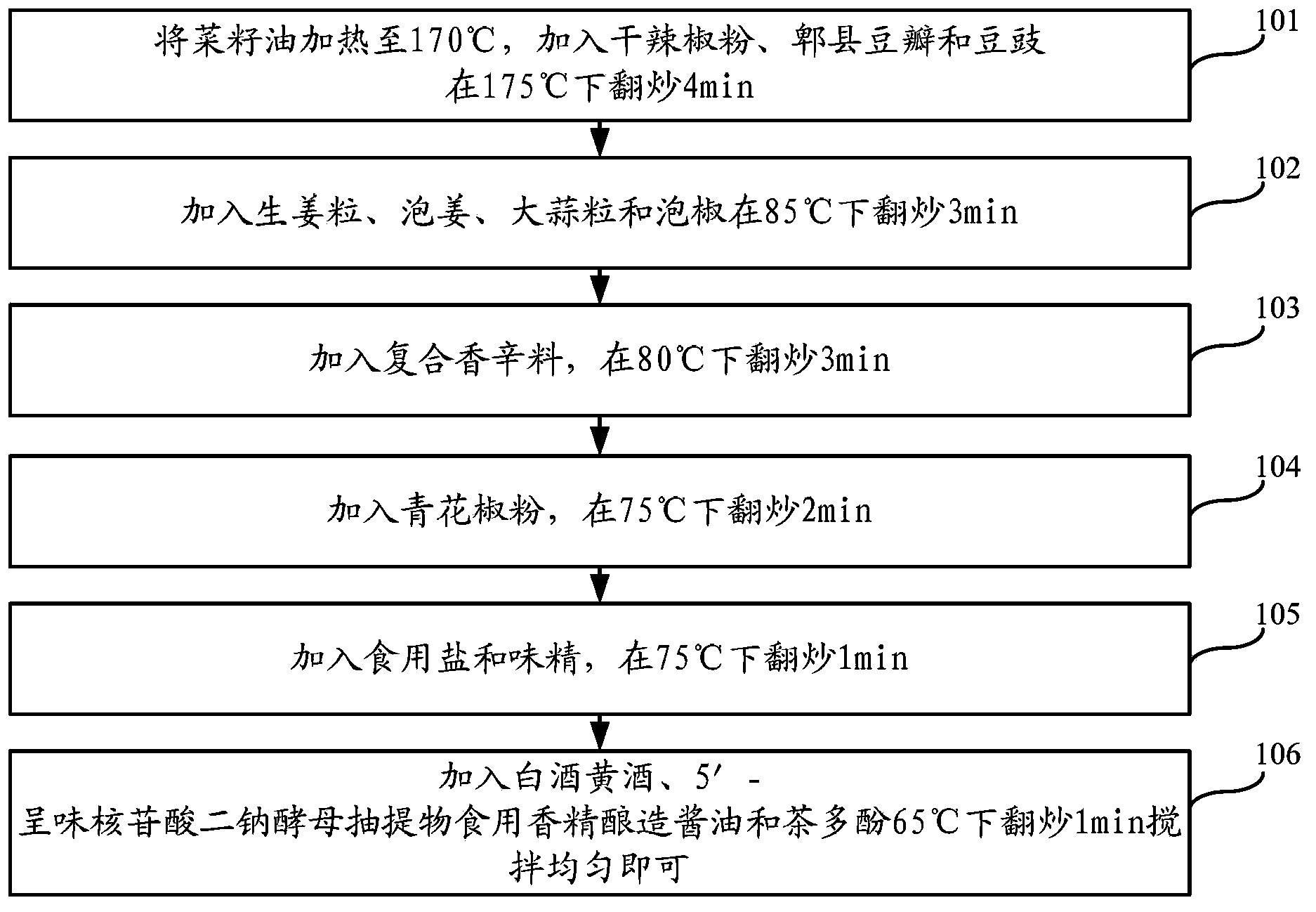

[0061] 2. Method

[0062] Equipment: TFSP-50 automatic frying pan; SP140 horizontal automatic packaging machine. Such as figure 2 as shown,

[0063] 101. Heat the rapeseed oil to 170°C, add dried chili powder, Pixian w...

Embodiment 2

[0070] 1. Formula (mass percentage)

[0071] 30% rapeseed oil, 25.5% Pixian watercress, 15% dried chili powder, 2% tempeh, 1.5% ginger, 1.5% pickled ginger, 10% garlic, 2% pickled pepper, 6.7% compound spices, 2.5% green pepper powder, 15% edible salt, 6% monosodium glutamate, 0.4% white wine, 4.5% rice wine, 0.2% 5'-taste nucleotide disodium, 0.4% Yeast extract, 0.8% food flavor, 1.5% brewed soy sauce, 0.05% tea polyphenols and 3% white sugar.

[0072] Compound spices: 0.4% star anise, 0.25% cumin, 0.1% cardamom, 0.15% bay leaf, 0.4% grass fruit, 1.6% sesame, 0.5% pepper, 0.15% clove, 0.15% coriander However, it can be used after crushing, using a ¢1mm sieve to crush.

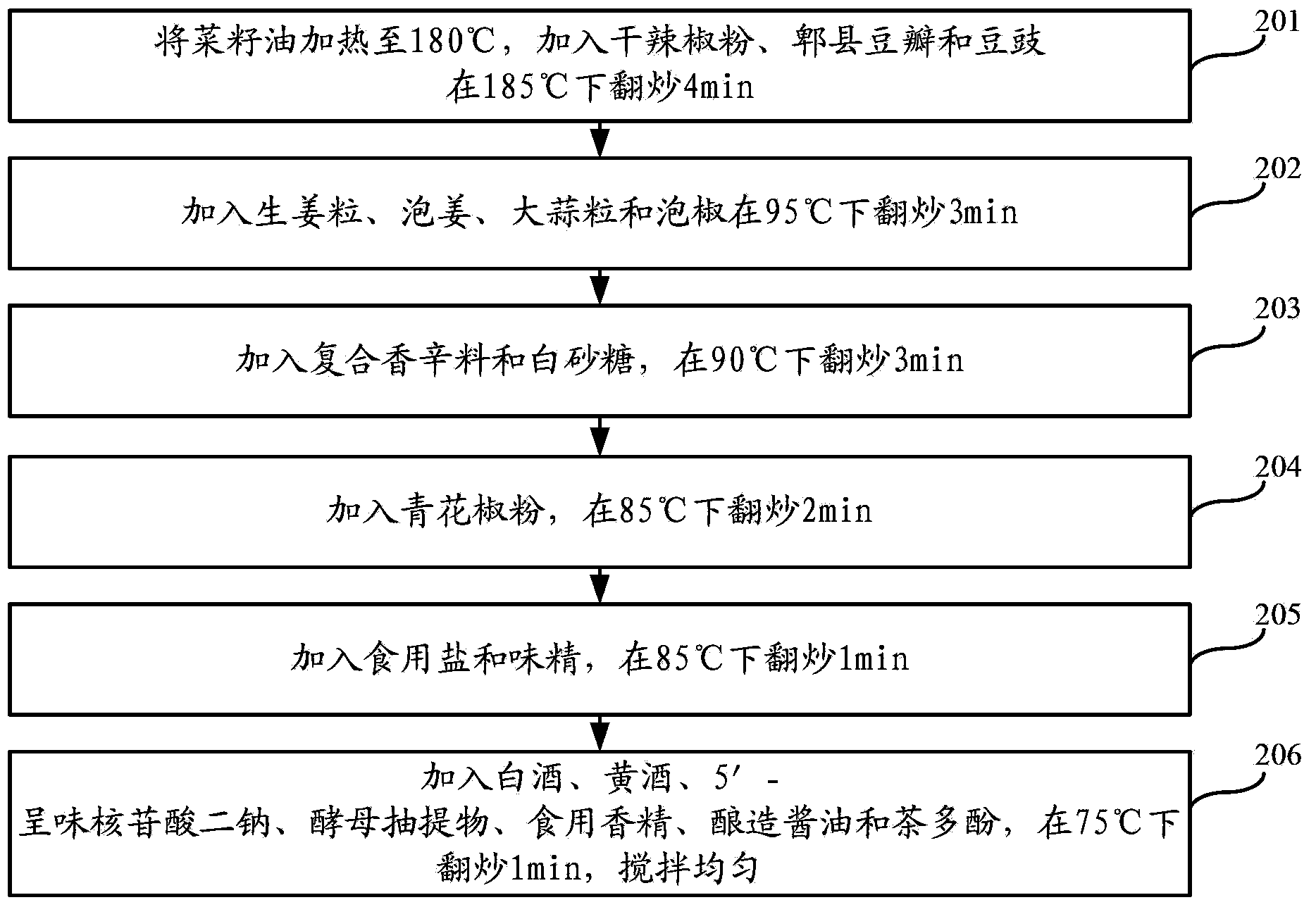

[0073] 2. Method

[0074] Equipment: TFSP-50 automatic frying pan; SP140 horizontal automatic packaging machine. Such as image 3 as shown,

[0075] 201. Heat rapeseed oil to 180°C, add dried chili powder, Pixian watercress and tempeh and stir-fry at 185°C for 4 minutes;

[0076] 202. Add ginger, pickle...

Embodiment 3

[0082] 1. Formula (mass percentage)

[0083] 28% rapeseed oil, 20% Pixian watercress, 13% dried chili powder, 1.8% tempeh, 1.3% ginger, 1.2% pickled ginger, 8% garlic, 1.3% pickled pepper, 5.5% compound spices, 1.8% green pepper powder, 14% edible salt, 4% monosodium glutamate, 0.3% white wine, 4% rice wine, 0.15% 5'-taste nucleotide disodium, 0.35% Yeast extract, 0.6% food flavor, 1% brewed soy sauce, 0.04% tea polyphenols and 2% white sugar.

[0084] Compound spices: 0.35% star anise, 0.2% cumin, 0.08% cardamom, 0.1% bay leaf, 0.35% grass fruit, 1.4% sesame, 0.4% pepper, 0.12% clove, 0.1% coriander However, it can be used after crushing, using a ¢1mm sieve to crush.

[0085] 2. Method

[0086] Equipment: TFSP-50 automatic frying pan; SP140 horizontal automatic packaging machine. Such as Figure 4 as shown,

[0087] 301. Heat rapeseed oil to 175°C, add dried chili powder, Pixian watercress and tempeh and stir-fry at 180°C for 4 minutes;

[0088] 302. Add diced ginger, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com