Method of evaluating inhibition of CCOS (computer controlled optical surfacing) process on errors under different frequencies

An evaluation method, 1.CCOS technology, applied in the direction of grinding/polishing equipment, workpiece feed movement control, manufacturing tools, etc., can solve the problems such as difficult application of high-frequency errors, and achieve the comparison of error suppression capabilities in different frequency bands Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

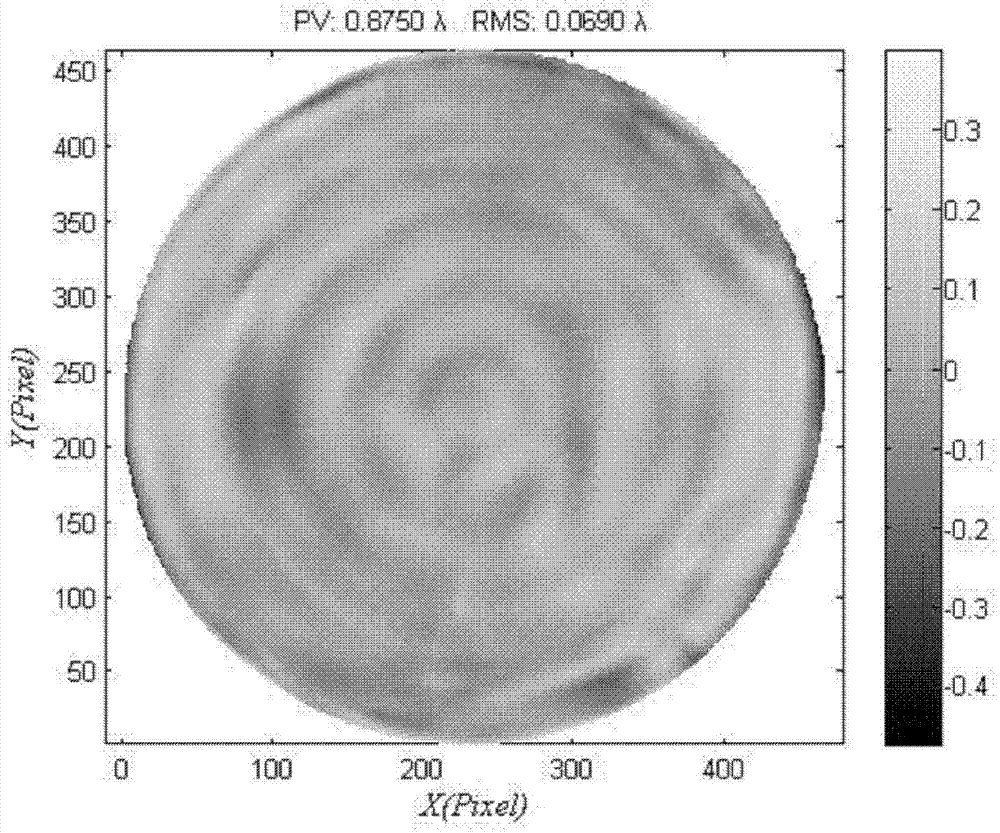

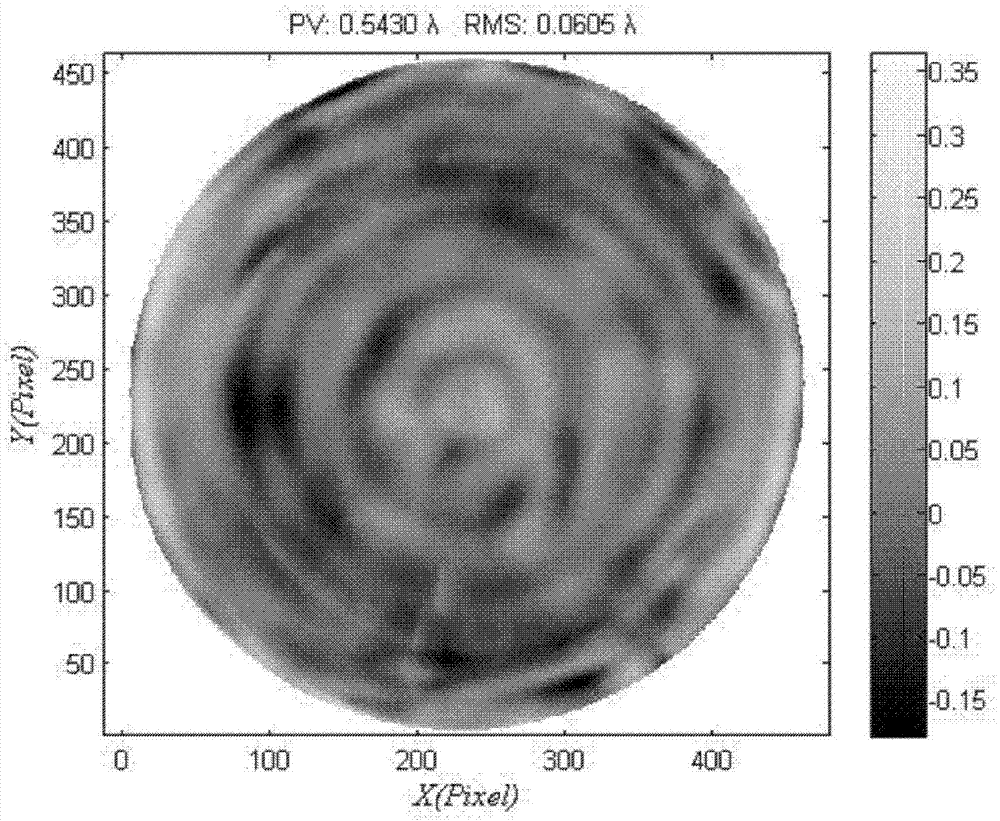

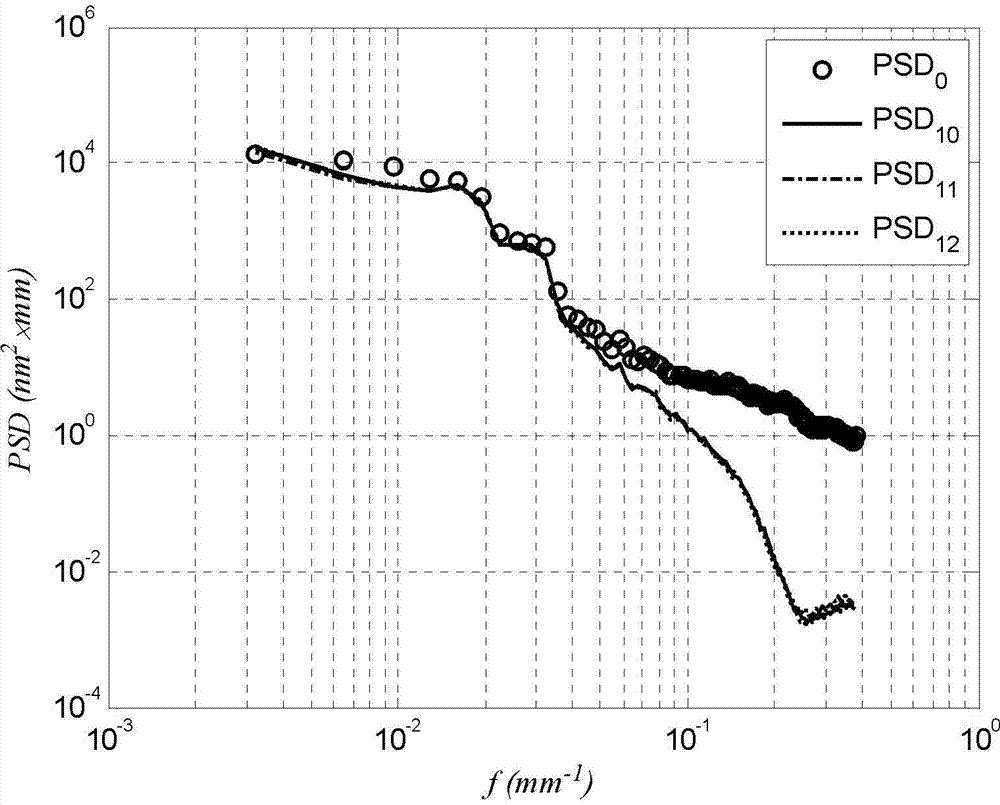

[0025] Such as figure 1 It shows the surface shape error distribution map obtained by the detection of flat glass ceramics before polishing in the embodiment of the present invention; the method utilizes the consistency of the correction process of surface shape error in CCOS polishing and the two-dimensional filtering process in signal processing in the mathematical model To analyze the ability of the CCOS polishing process to suppress errors in different frequency bands from the perspective of spatial spectrum, firstly, a mathematical model of smooth spectral function is established based on the convolution model of material removal and power spectral density function, and then the optical components before and after pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com