A Diamond Wire Cutting Machine with Completely Planar Wiring

A diamond wire, flat technology, applied in the direction of stone processing tools, stone processing equipment, fine working devices, etc., can solve the problems of manual adjustment inconsistency, limited processing accuracy of parts, high material cost and labor cost, and achieve material Cost and labor replacement time cost reduction, simple processing and assembly, the effect of reducing cutting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

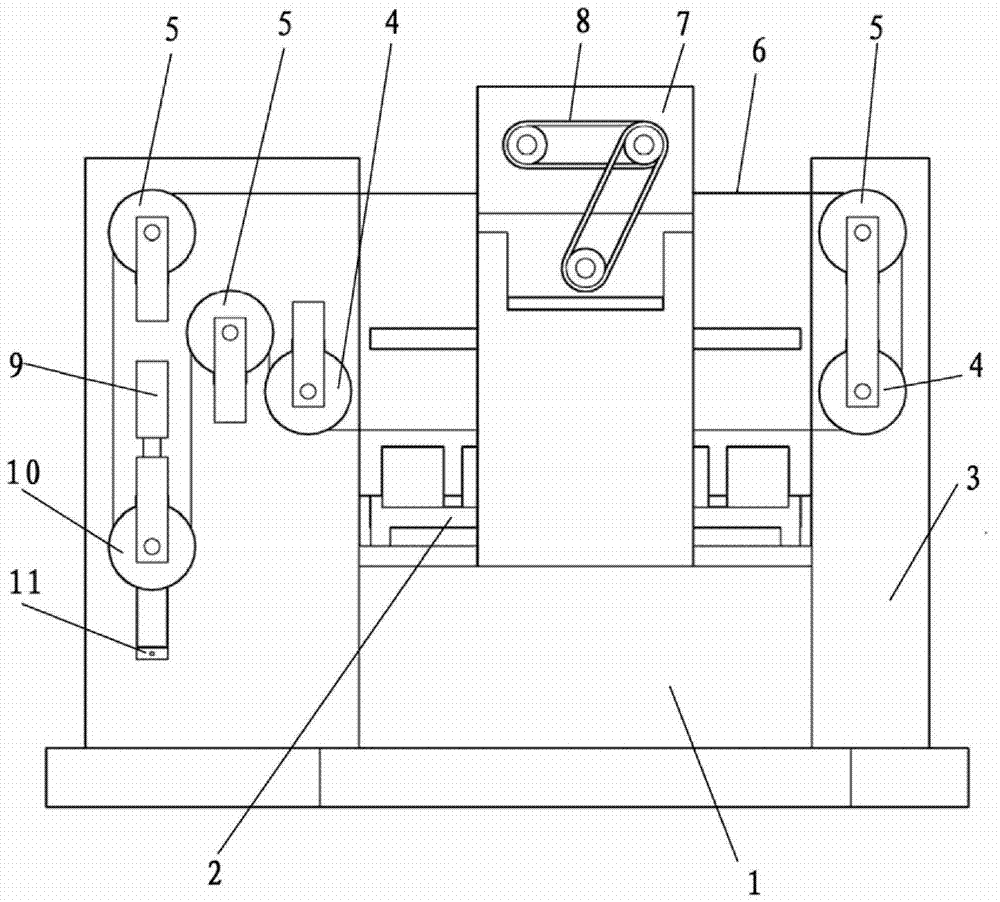

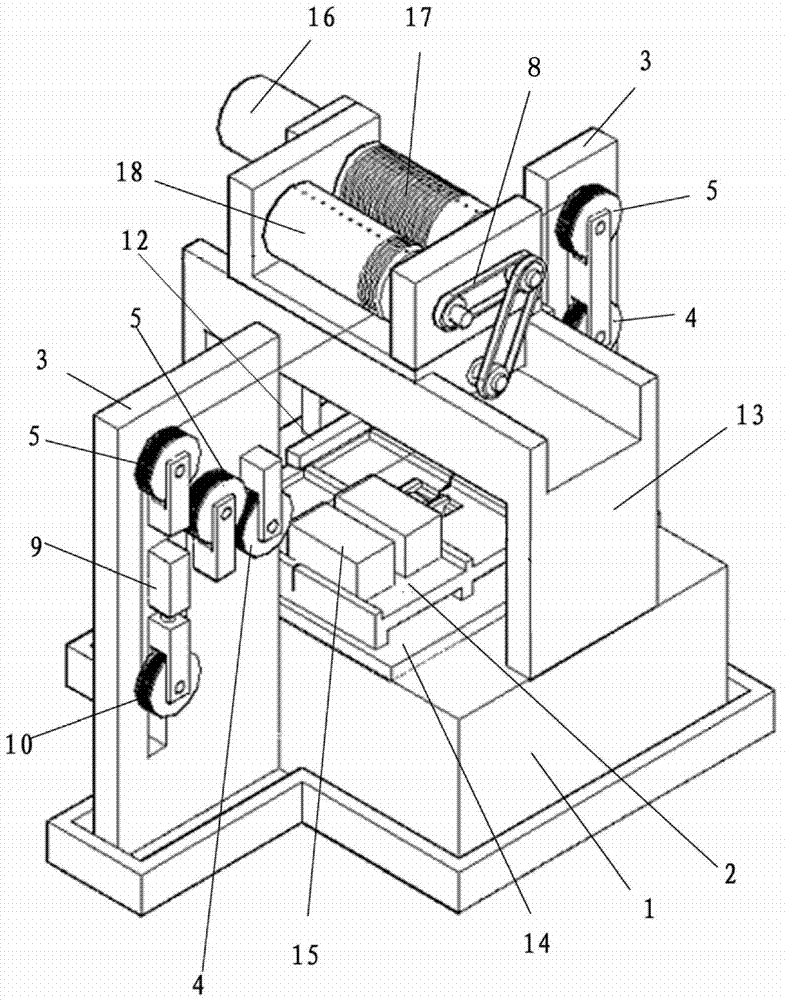

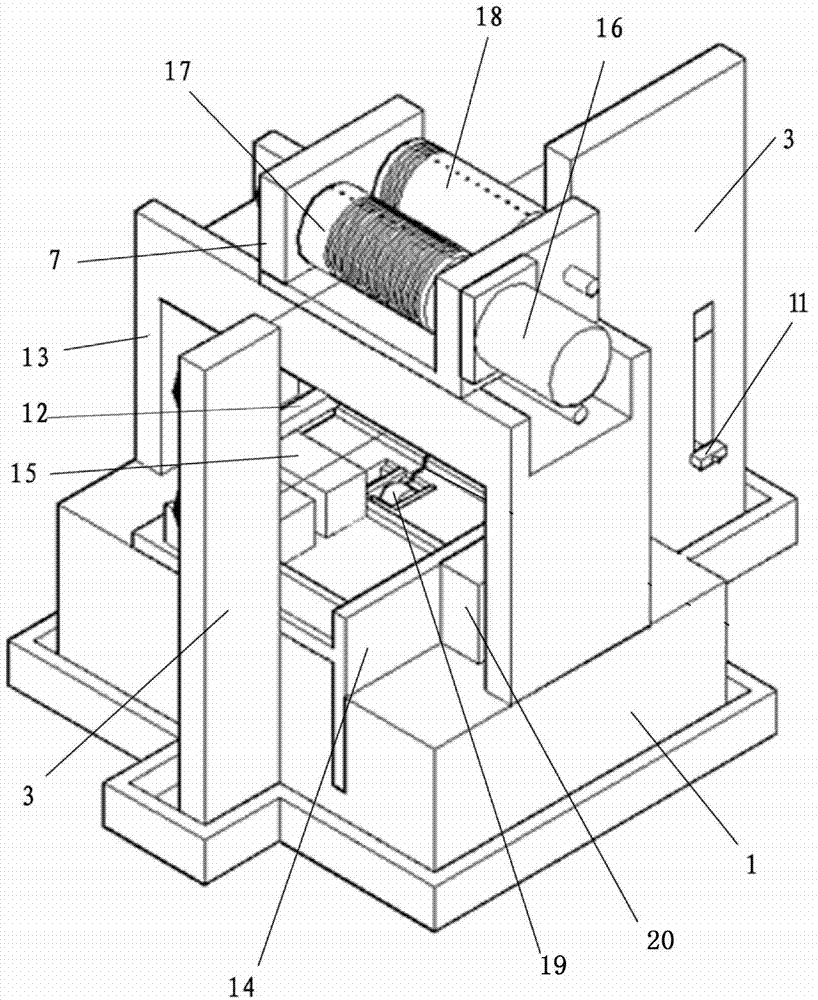

[0040] Such as Figure 1-Figure 5 As shown, a diamond wire cutting machine with completely planar wiring according to the present invention includes a bed 1 and a wire storage mechanism, a wire transport mechanism, and a lifting platform 14 installed on the bed.

[0041] The lifting platform is driven by a ball screw pair 20. The lifting platform is equipped with several clamps 2 and at least one cutting buffer wheel 19 (buffering the diamond wire at the end of cutting). This part of the structure is similar to the prior art. When After starting the motor of the ball screw pair, let the screw rotate, and the lifting platform will rise or fall at a certain speed with the fixture and the workpiece on it.

[0042] The wire storage mechanism includes two wire storage drums installed in parallel on the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com