A kind of saponins polysaccharide gum and preparation method thereof

A technology of polysaccharide gum and acacia, which is applied in the field of acacia extract, can solve the problem of high content of water-insoluble products and achieve good gel properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

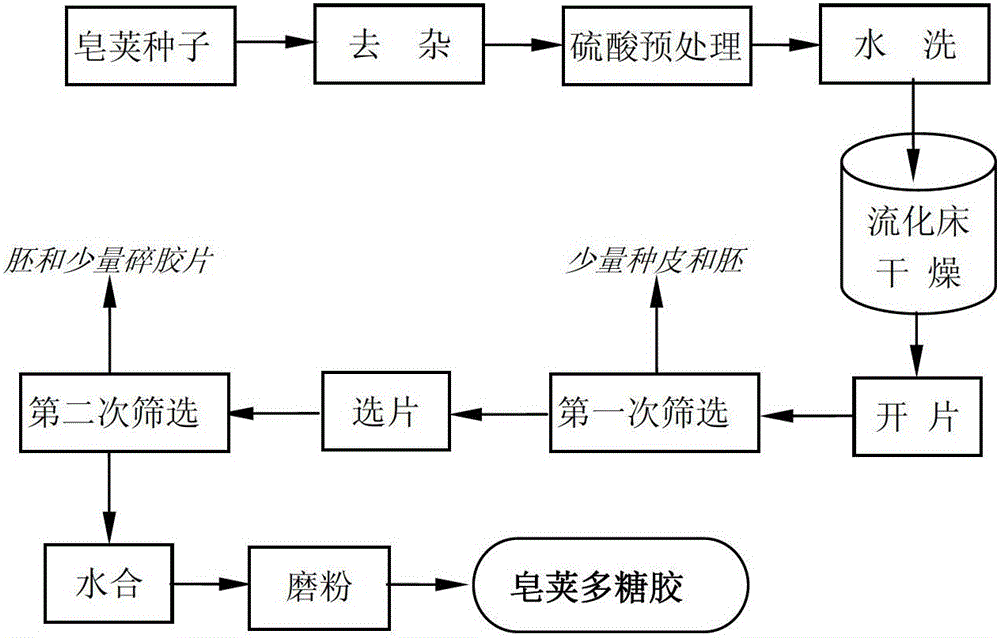

Method used

Image

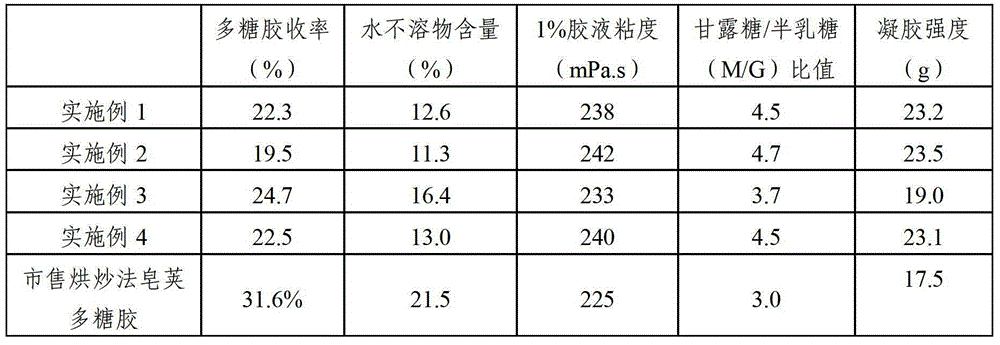

Examples

Embodiment 1

[0047] Embodiment 1: the preparation method of saponins polysaccharide gum

[0048] 1. Sulfur treatment: Submerge 500g of acacia seeds (9.2% water content, 1.5% impurity content) in 900mL sulfuric acid solution with a volume concentration of 55%, and perform acid treatment in a 60°C water bath for 2 hours;

[0049] 2. Hulling and drying: Rinse the acid-treated acacia seeds with 1500mL of cold water, and scrub to remove the carbonized seed shells on the outer layer. Dry the shelled seeds in a fluidized bed drying oven at 90°C for 30 minutes;

[0050] 3. Opening: using a hammer mill, the distance between the blade and the fixed tooth plate is 7mm;

[0051] 4. Slice selection and screening: the aperture of the screen for the first screening is 13 mesh, the rotating speed of the pulverizer in the sheet selection section is 3200 rpm, and the aperture of the screen for the second screening is 22 mesh, namely the polysaccharide film;

[0052] 5. Hydrated polysaccharide film: the pol...

Embodiment 2

[0053] Embodiment 2: the preparation method of saponins polysaccharide gum

[0054] 1. Sulfur treatment: Submerge 500g of acacia seeds (water content 8.9%, impurity content 1.6%) in 1000mL sulfuric acid solution with a volume concentration of 55%, and perform acid treatment in a 70°C water bath for 3 hours;

[0055]2. Shelling and drying: then rinse the acid-treated acacia seeds with 1500mL of cold water, and scrub to remove the carbonized seed shells on the outer layer, and dry the shelled seeds in a fluidized bed drying oven at 90°C for 30 minutes;

[0056] 3. Opening: using a hammer mill, the distance between the blade and the fixed tooth plate is 8mm;

[0057] 4. Film selection and screening: The aperture of the first screening screen is 14 mesh. The speed of the shredder in the selection section is 3200rpm. The aperture of the second screening screen is 24 mesh, namely the polysaccharide film;

[0058] 5. Hydrated polysaccharide film: the polysaccharide film is hydrate...

Embodiment 3

[0059] Embodiment 3: the preparation method of saponins polysaccharide gum

[0060] 1. Sulfur treatment: immerse 500g of acacia seeds (water content 9.5%, impurity content 1.1%) in 800mL of sulfuric acid solution with a volume concentration of 55%, and perform acid treatment in a 50°C water bath for 1 hour;

[0061] 2. Shelling and drying: then rinse the acid-treated acacia seeds with 1500mL of cold water, and scrub to remove the carbonized seed shells on the outer layer, and dry the shelled seeds in a fluidized bed drying oven at 90°C for 30 minutes;

[0062] 3. Opening: using a hammer mill, the distance between the blade and the fixed tooth plate is 5mm;

[0063] 4. Film selection and screening: the first screening screen has an aperture of 12 mesh. The speed of the shredder in the selection section is 3200rpm. The aperture of the second screening sieve is 20 mesh, namely the polysaccharide film;

[0064] 5. Hydrated polysaccharide film: the polysaccharide film is hydrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com