Modified alkyd resin and preparation method thereof

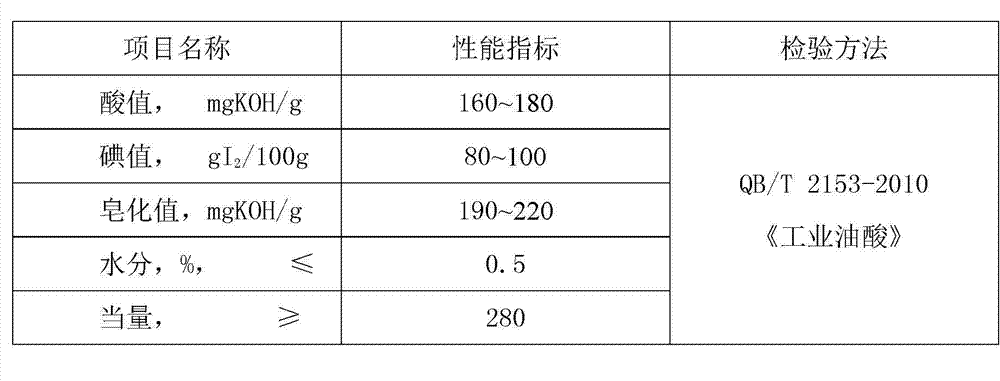

A technology of alkyd resin modification, applied in polyester coatings, coatings, etc., can solve the problems of lack of gloss and weather resistance, large amount of oleic acid used, high production cost, etc., achieve low price of finished products, and increase utilization value , Low cost of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

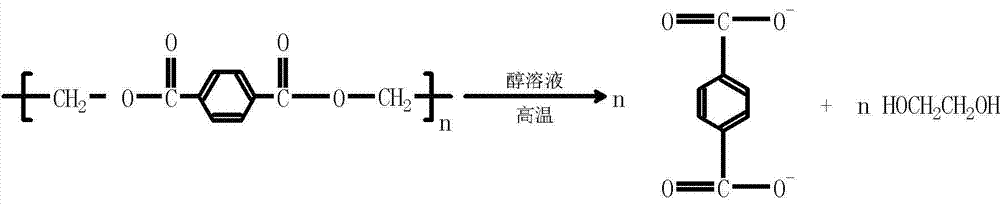

[0037] (1) Alcoholysis of waste polyester blocks: Place 21 parts of waste polyester blocks in an alcohol solution, heat to cause decomposition reaction, and decompose into terephthalic anhydride and ethylene glycol;

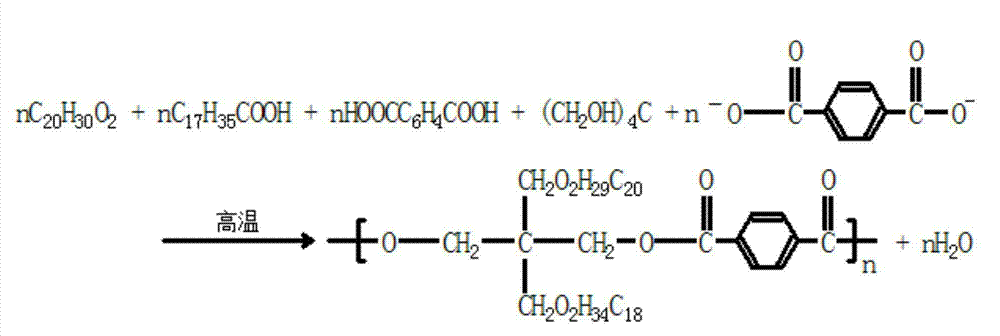

[0038] (2) Alkyd reaction: in (1) add 20 parts of mixed fatty acid, 5 parts of PTA leftovers, 6.5 parts of rosin, 4 parts of pentaerythritol; increase the temperature at a rate of 1.5℃ / min, and turn on the stirrer when the temperature reaches 150℃ , Stir at 2 revolutions / min, continue to heat up to 270°C and heat for 1 hour to obtain a solid alkyd resin; the acid value of the solid alkyd resin is not more than 12 mgKOH / g;

[0039] (3) Dilute: Stir 38 parts of 200# solvent oil in the reaction kettle, then add the solid alkyd resin prepared in (2) to it, stir at 60 revolutions / min for 30 minutes, and filter to obtain modified alkyd resin. Its solid content is 55% and its viscosity is 180s.

Embodiment 2

[0041] (1) Alcoholysis of waste polyester blocks: Place 10 parts of waste polyester blocks in an alcohol solution, heat them to cause decomposition reactions, and decompose them into terephthalic anhydride and ethylene glycol;

[0042] (2) Alkyd reaction: in (1) add 22.8 parts of mixed fatty acid, 5.6 parts of PTA leftovers, 7.6 parts of rosin, 4.3 parts of pentaerythritol; increase the temperature at a rate of 2℃ / min, and turn on the stirrer when the temperature reaches 150℃ , Stir at 1.5 revolutions / min, continue to heat up to 280°C and keep for 1 hour to obtain a solid alkyd resin; the acid value of the solid alkyd resin is not more than 12 mgKOH / g;

[0043] (3) Dilute: Stir 40.5 parts of 200# solvent oil in the reaction kettle, then add the solid alkyd resin prepared in (2) to it, stir at 55 revolutions / min for 35 minutes, and filter to obtain modified alkyd resin. Its solid content is 56% and its viscosity is 200s.

Embodiment 3

[0045] (1) Alkyd reaction: in (1) add 25 parts of mixed fatty acid, 6 parts of PTA leftovers, 8.5 parts of rosin, 5 parts of pentaerythritol; increase the temperature at a rate of 2.5°C / min, and turn on the stirrer when the temperature reaches 150°C , Stir at 2 revolutions / min, continue to heat up to 290°C and keep for 1.5 hours to obtain a solid alkyd resin; the acid value of the solid alkyd resin is not more than 12 mgKOH / g;

[0046] (2) Dilute: Stir 42 parts of 200# solvent oil in the reaction kettle, then add the solid alkyd resin prepared in (2) to it, stir at 50 revolutions / min for 40 minutes, and filter to obtain modified alkyd resin. Its solid content is 56.5% and its viscosity is 300s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com