Epoxy glue membrane

A technology of epoxy adhesive film and epoxy value, which can be used in epoxy resin adhesives, adhesives, film/sheet adhesives, etc., and can solve the problems of low shear strength and peel strength of aluminum materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

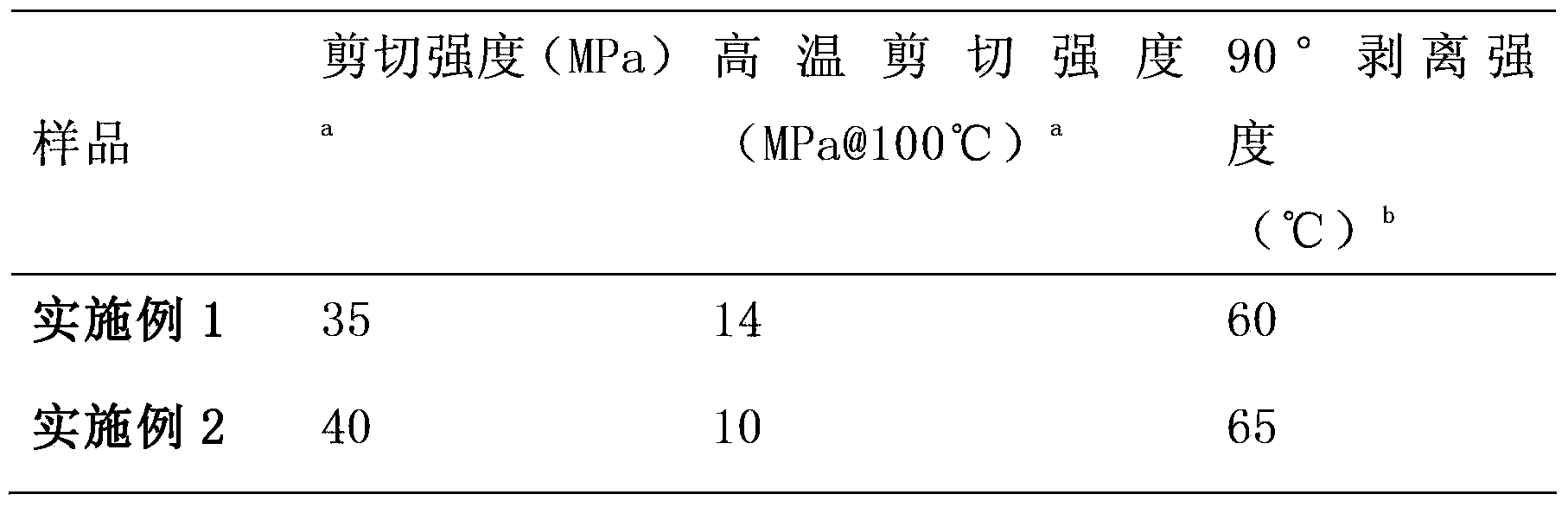

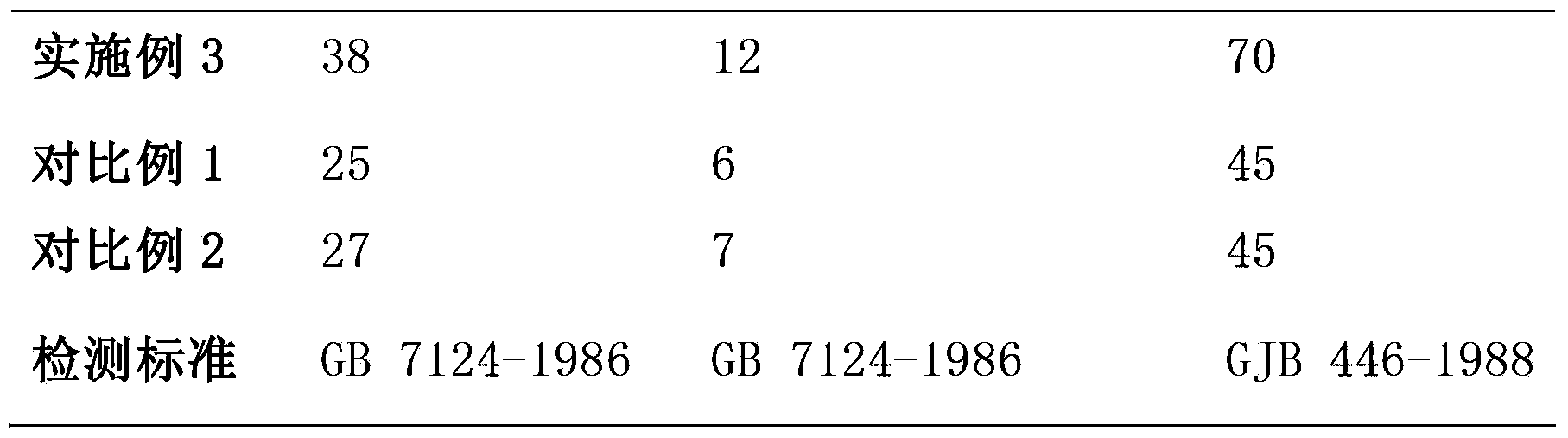

Examples

Embodiment 1

[0021] 1. Preparation of toughening agent

[0022] After mixing 78g of epoxy resin 618, 1.44g of methacrylic acid, and 0.6g of triphenylphosphine in the reactor, react at a speed of 300-500 rpm and a temperature of 110°C for 1.5 hours, and then 200 rpm 19.6g of octyl acrylate and 0.64g of azobisisobutyronitrile were added dropwise at the same time at a rotating speed. After the dropping, the temperature was raised to 130°C and the rotating speed was 300-500 rpm to continue the reaction for 30 minutes and discharge.

[0023] 2. Preparation of rubber

[0024] Weigh the raw materials with the following mass percentages, and fully stir the raw materials at a temperature of 50-60°C at 300-500 rpm to prepare the rubber compound:

[0025] 40g of bisphenol A epoxy resin with an epoxy value of 0.2mol / 100g, 20g of bisphenol A epoxy resin with an epoxy value of 0.44mol / 100g, 30g of the toughening agent prepared in step 1, curing agent Dyhard100S6g, rheology Auxiliary agent AEROSIL3803g...

Embodiment 2

[0029] 1. Preparation of toughening agent

[0030] After mixing 73g of epoxy resin 618, 1.2g of methacrylic acid and 0.6g of triphenylphosphine in the reactor, react at a speed of 300-500 rpm and a temperature of 110°C-130°C for 2 hours, then 200-300 18g of octyl acrylate and 0.7g of azobisisobutyronitrile were added dropwise at the same time at a rotation speed of 120°C to 140°C, and the speed of rotation was 300 to 500rpm to continue the reaction for 20 minutes.

[0031] 2. Preparation of rubber

[0032] Weigh the raw materials with the following mass percentages, and fully stir the raw materials at a temperature of 50-60°C at 300-500 rpm to prepare the rubber compound:

[0033] 30g of bisphenol A epoxy resin with an epoxy value of 0.2mol / 100g, 20g of bisphenol A epoxy resin with an epoxy value of 0.44mol / 100g, 40g of the toughening agent prepared in step 1, curing agent Dyhard100S7g, rheology Auxiliary agent AEROSIL3802g, accelerator Dyhard3000.5g, silane coupling agent 0...

Embodiment 3

[0037] 1. Preparation of toughening agent

[0038] After mixing 75g of epoxy resin 618, 1.3g of methacrylic acid, and 0.75g of triphenylphosphine in the reactor, react at a speed of 300-500 rpm and a temperature of 110°C-130°C for 1.5-3 hours, and then 200 Add 19g of octyl acrylate and 0.7g of azobisisobutyronitrile dropwise at a speed of ~300 rpm. After the addition is complete, raise the temperature to 120°C-140°C and continue the reaction at a speed of 300-500 rpm for 45 minutes. .

[0039] 2. Preparation of rubber

[0040] Weigh the raw materials with the following mass percentages, and fully stir the raw materials at a temperature of 50-60°C at 300-500 rpm to prepare the rubber compound:

[0041] 20g of bisphenol A epoxy resin with an epoxy value of 0.2mol / 100g, 20g of bisphenol A epoxy resin with an epoxy value of 0.44mol / 100g, 50g of the toughening agent prepared in step 1, and 7.5g of curing agent Dyhard100S, Rheology additive AEROSIL3801.5g, Dyhard5000.5g, silane c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com