A modeling optimization method for cleaner production of cement clinker firing process

A technology of cement clinker and clean production, which is applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of saving costs, avoiding risks and economic losses, and promoting clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the examples.

[0054] The present invention comprises the following steps:

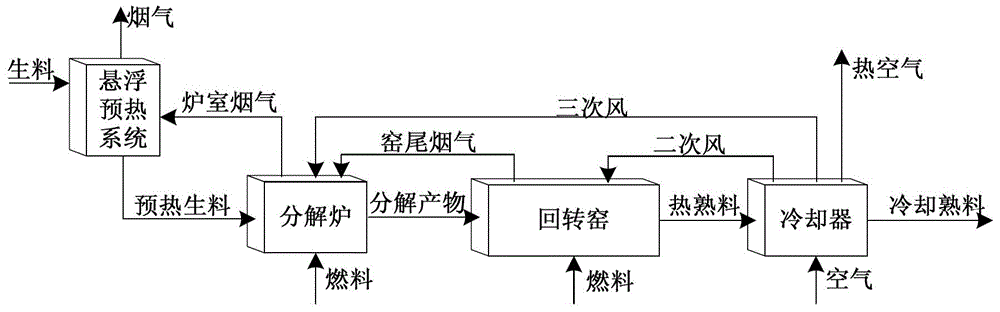

[0055] Step 1. Create a flowchart

[0056] (1) Select each unit operation model according to the operation tasks of each production process of clinker firing.

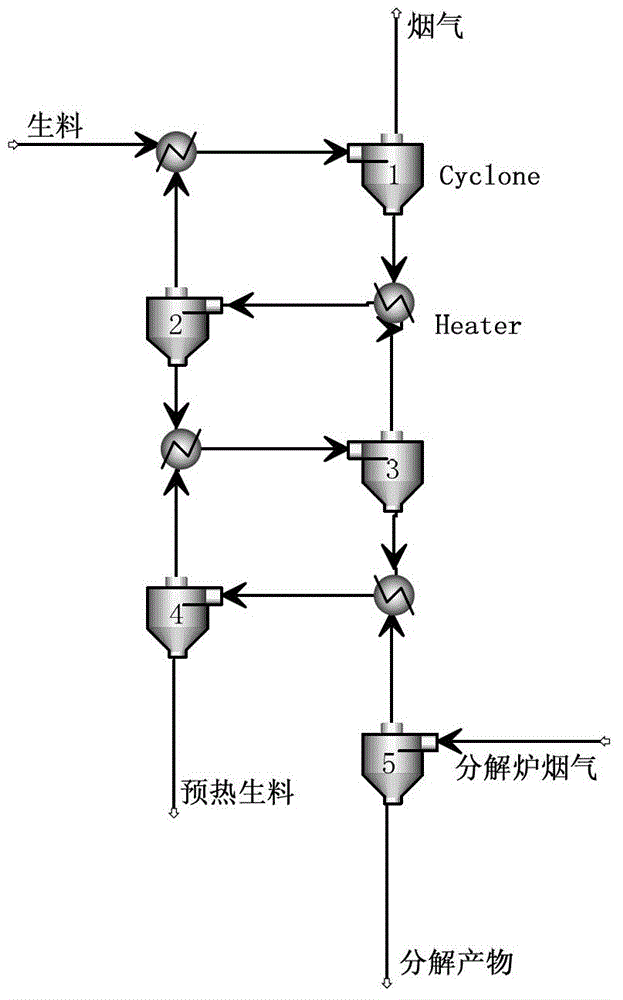

[0057] 1) Select the separation module Cyclone and the heat transfer module Heater in Aspen Plus to simulate the gas-solid separation and gas-solid heat transfer tasks of the suspension preheating subsystem.

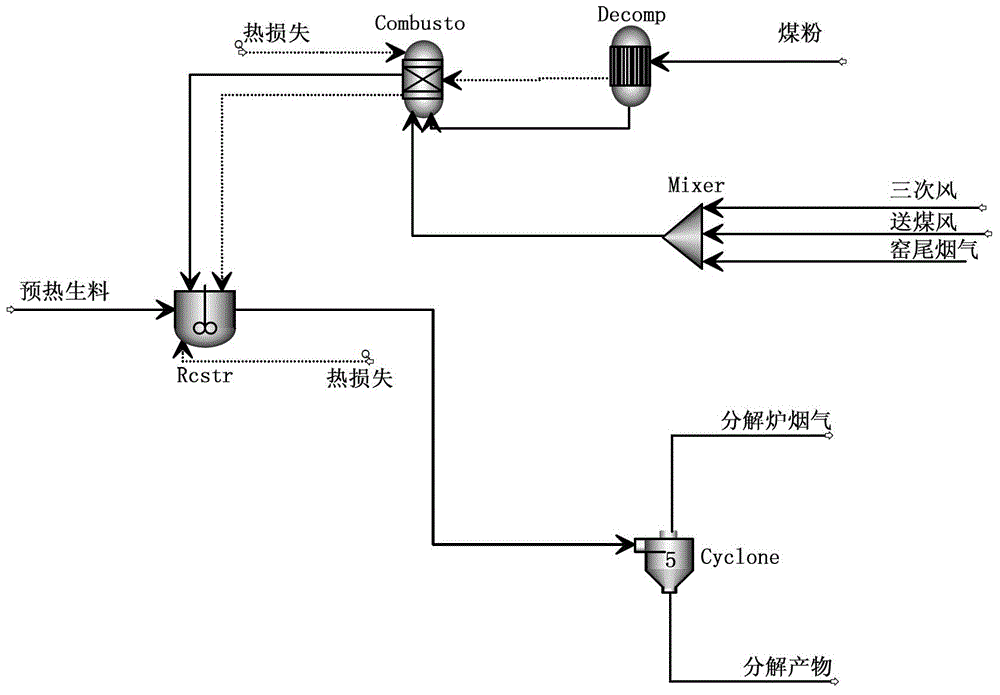

[0058] 2) Choose the RCSTR module, the mixing module Mixer and the more mature pulverized coal combustion module to simulate part of the fuel combustion, gas mixing, gas-solid heat transfer and decomposition tasks of most raw materials.

[0059] 3) Choose multi-level RCSTR module, gas-solid separation module, mixing module Mixer and pulverized coal combustion module to simulate the tasks of raw meal decomposition, mineral calcination, fuel combu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com