Modeling optimization method for improving value of soybean degreased by-products in industrial production

A soybean degreasing and optimization method technology, applied in the direction of comprehensive factory control, comprehensive factory control, instruments, etc., can solve the problems of lack of theoretical basis and technical support for feasibility assessment of energy-saving schemes for adjusting and optimizing processes, and less research on technical energy consumption. Achieve the effect of increasing the value of by-products and simplifying the simulation calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the following drawings will be briefly introduced in the embodiments. It should be understood that the following drawings only show a certain embodiment of the present invention, so It should not be regarded as a limitation on the scope, and those skilled in the art can also obtain other related drawings according to these drawings without creative work.

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

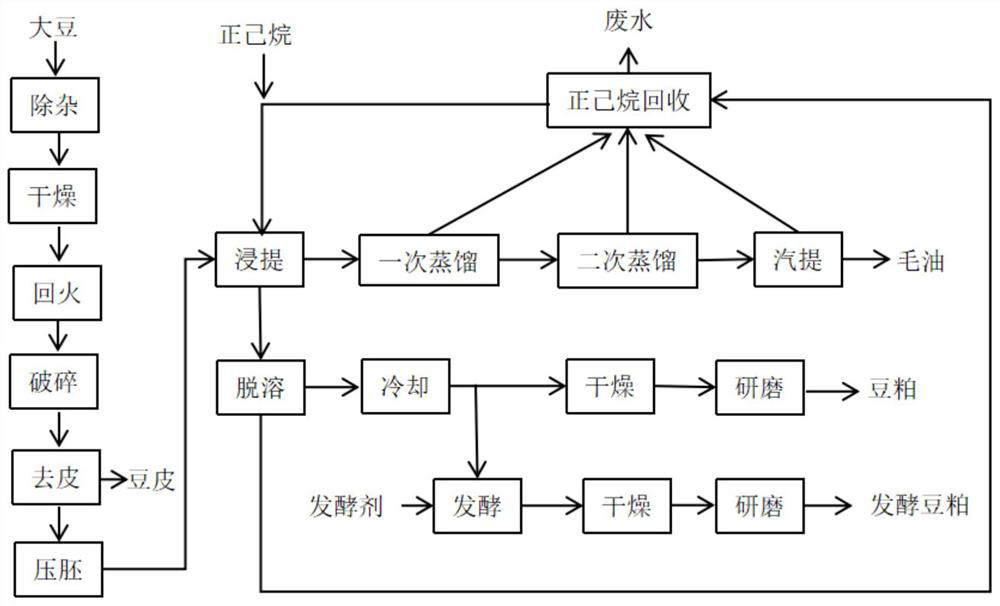

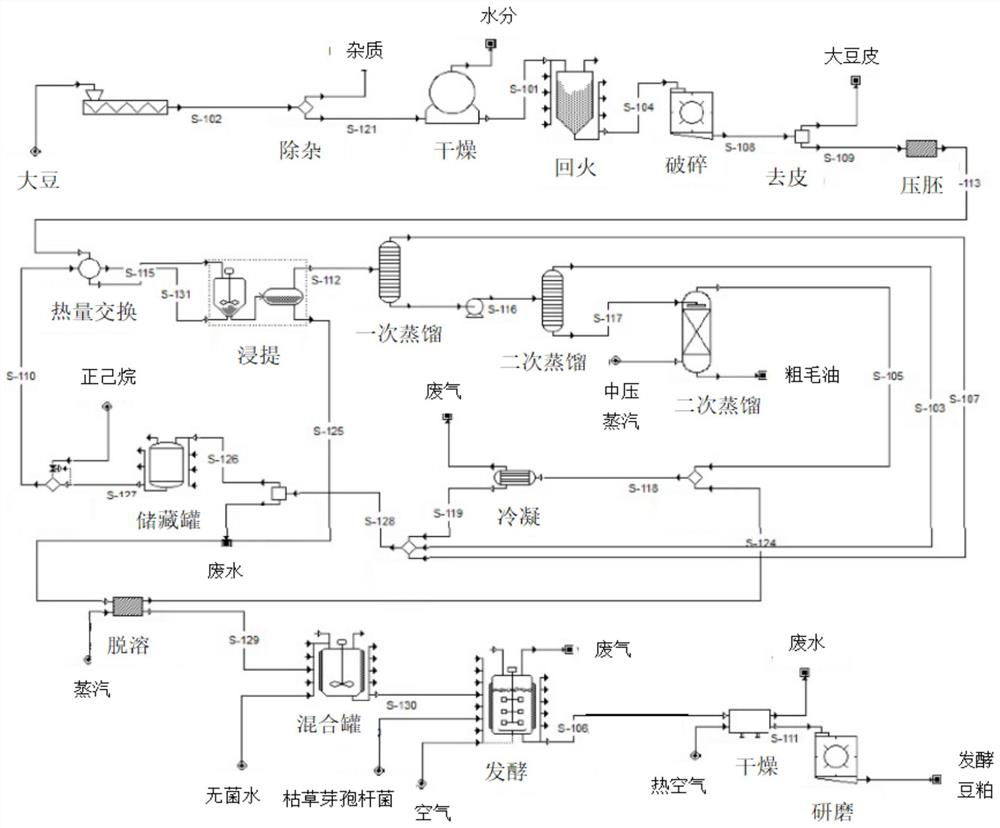

[0043] see figure 1 and figure 2 , the present invention improves the modeling optimization method of the by-product value after soybean degreasing in industrial production, and concrete operation method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com