Failure analysis method for MIM capacitor

A technology of failure analysis and capacitance, which is applied in the manufacture of electrical components, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problem that it is difficult to accurately determine the relative position of the leakage area of the MIM capacitor, and achieve the effect of easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

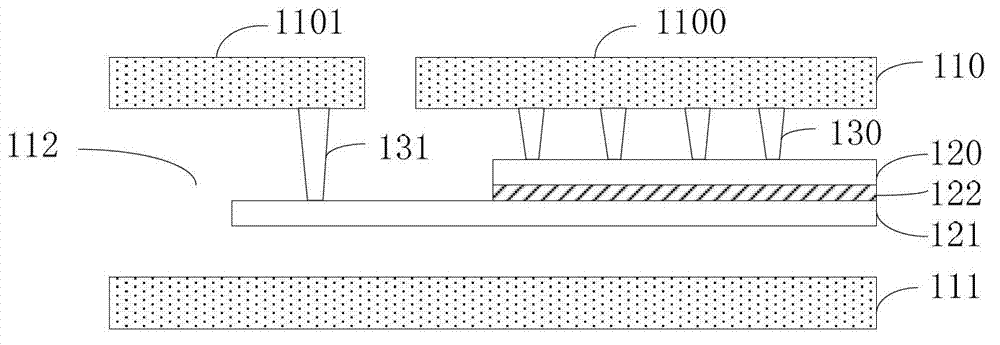

[0020] It should be noted that, in any embodiment of the present invention, the MIM capacitive device is located on a silicon substrate and distributed in multiple layers, which at least includes an upper plate, a lower plate, and a capacitor between the upper plate and the lower plate. There are also multiple metal layers vertically distributed on the silicon substrate, and a dielectric layer is filled between adjacent metal layers; wherein, the upper and lower plates can be one of the metal layers respectively, made of metal materials, It can also be formed between two adjacent metal layers and made of TiN or TaN material; the upper and lower plates are respectively electrically connected to the first and second circuit regions of the first metal layer on the silicon substrate through Via wiring. The above structure and figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com