A kind of photovoltaic module and packaging method thereof

A photovoltaic module and integrated technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of low photoelectric conversion efficiency of solar photovoltaic modules, large thickness of solid adhesive layer, easy aging and discoloration of solid adhesive layer, etc., to achieve photoelectric conversion High efficiency, not easy to change color and yellow, reduce the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

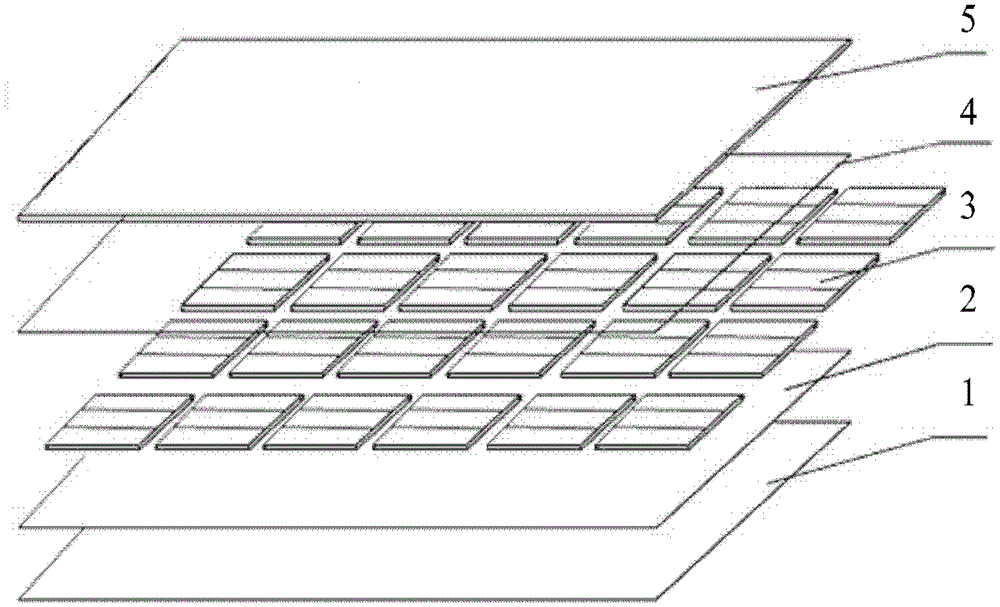

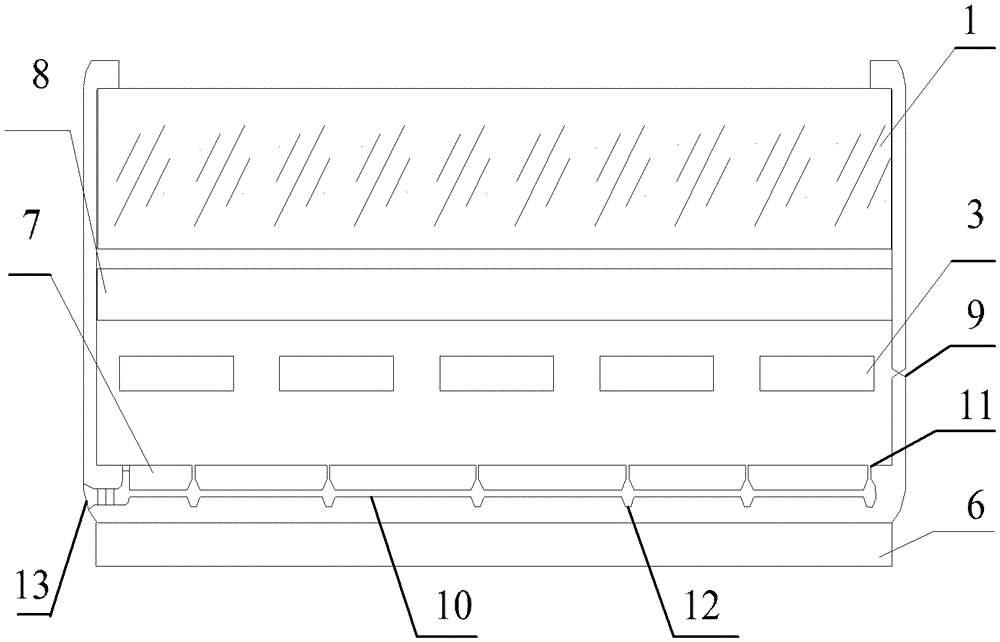

[0052] On the basis of the above technical solutions, this embodiment provides a photovoltaic module, refer to figure 2 , the photovoltaic module includes:

[0053] A back plate 6 matching the shape of the battery strings 3 connected in series;

[0054] The elastic shell 7 bonded on the back plate 6, the elastic shell 7 is an integrally formed structure, including a bottom plate and a side wall, the side wall of the elastic shell is provided with a bus outlet 9; The base plate of the housing 7 is provided with an air extraction channel 10, and the air extraction channel 10 communicates with the space on the upper surface of the base plate through a plurality of air guide holes 11 arranged on the base plate; the base plate is provided with an air extraction port 13. The air pumping port 13 communicates with the air pumping channel 10; the plurality of air guide holes 11 correspond to the cell gaps of the battery string 3; in order to ensure the strength and sealing of the pho...

Embodiment 2

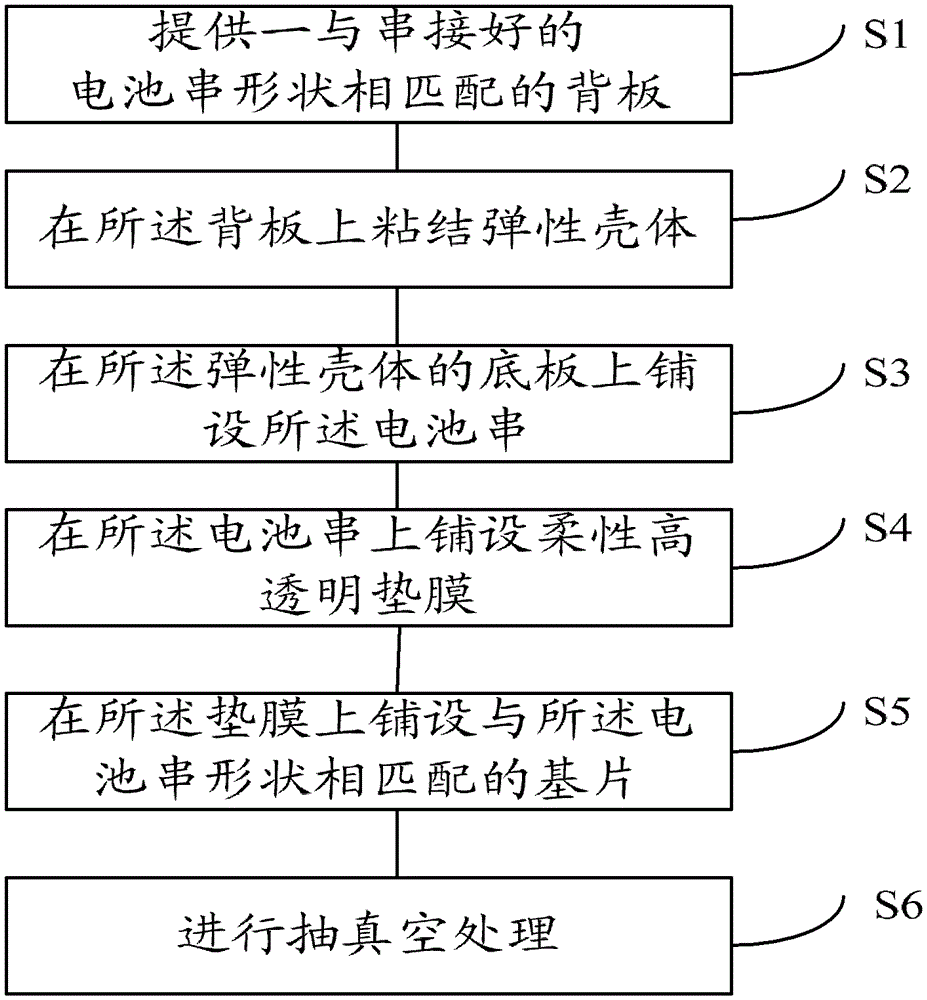

[0069] This embodiment provides a packaging method for photovoltaic modules, refer to image 3 , the method includes:

[0070] Step S1: providing a back plate matching the shape of the battery strings connected in series.

[0071] The shape of the back plate is determined by the shape of the battery string. When the battery string is square, the back plate is a corresponding square shape; when the battery string is circular, the back plate is Corresponding to the circular shape, that is to design a corresponding structure of the back plate according to the shape of the battery string.

[0072] In order to speed up the heat dissipation speed of the photovoltaic module, the backplane adopts a metal backplane, and the metal material has excellent heat dissipation performance, which can quickly dissipate the heat generated by the photovoltaic module during photoelectric conversion, and avoid the solar battery sheet being damaged due to temperature rise. The reduction of photoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com