Air bag support for improving the formation performance of flexible packaging lithium-ion batteries and its application method

A lithium-ion battery and flexible packaging technology, which is applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, climate sustainability, etc., can solve the problems of fusion of air bag pits, reduction of effective gas storage volume of air bag, etc., to save production Cost, improve battery efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

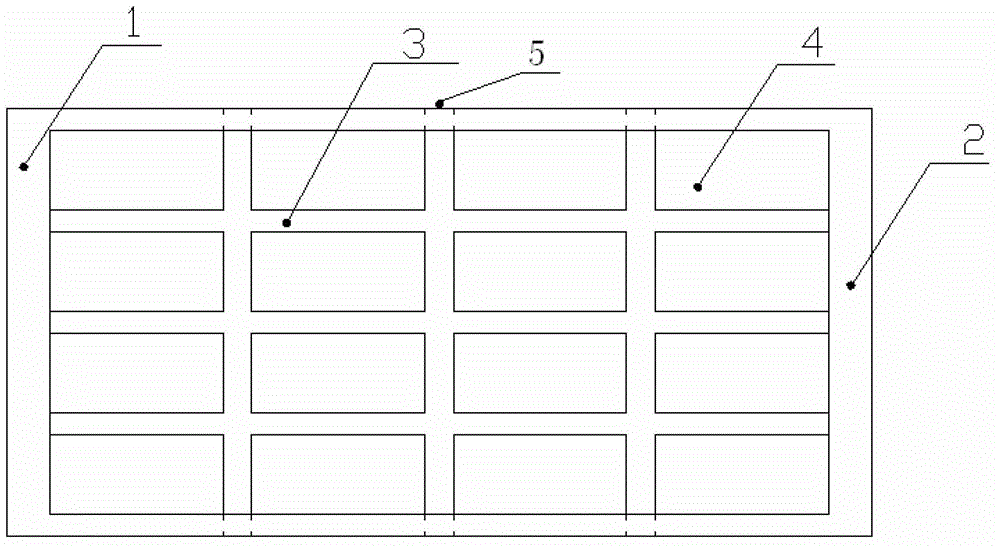

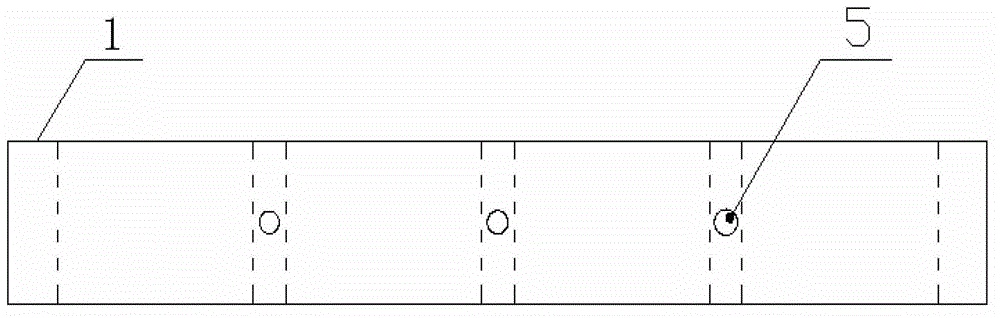

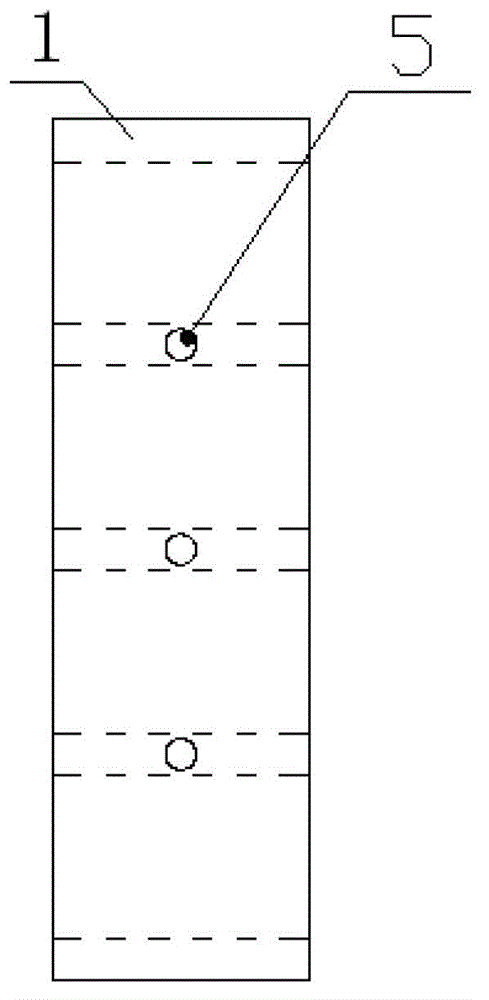

[0027] See figure 1 The battery of this embodiment is a polymer cell type 354364 (cell thickness 3.5mm, width 43mm, length 64mm), and the air bag 7 has a length of 64±0.5mm and a width of 45.0±2.0mm. When the bracket body 1 is not used, the effective width of the air bag 7 is reduced by 10.0mm due to the thermal diffusion of the head during the vacuum pre-sealing after liquid injection, and the effective gas storage space is significantly reduced. The battery body 6 has serious flatulence after pre-charging , The ratio of the air bag 7 rupture due to the reduced volume of the air bag 7 during shaping is 0.10%. The bracket body 1 used in the present invention has a base material of PP, and the size of the bracket is 40.0±1.0 mm in length, 5.0±1.0 mm in width, and 1.2±0.1 mm in thickness. After the bracket body 1 is used, the heat radiation of the head is reduced to 2mm during pre-sealing, and the air bag 7 rupture ratio is 0 during shaping.

Embodiment 2

[0029] The battery of this embodiment is a polymer cell 1072170 type (cell thickness 10mm, width 72mm, and length 170mm), and the air bag 7 has a length of 170±0.5mm and a width of 60.0±2.0mm. When the bracket body 1 is not used, the effective width of the air bag 7 is reduced by 15.0mm due to the thermal diffusion of the head during the vacuum pre-sealing after liquid injection, and the effective gas storage space is significantly reduced. The battery body 6 has serious flatulence after pre-charging , The ratio of the air bag 7 rupture due to the smaller volume of the air bag 7 during shaping is 0.17%. The bracket body 1 used in the present invention has a base material of PE, and the size of the bracket is 140.0±1.0 mm in length, 4.0±0.5 mm in width, and 9.8±0.1 mm in thickness. After the bracket body 1 is used, the heat radiation of the head is reduced to 1.0 mm during pre-sealing, and the air bag 7 rupture ratio is 0 during shaping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com