led backlight short circuit protection circuit

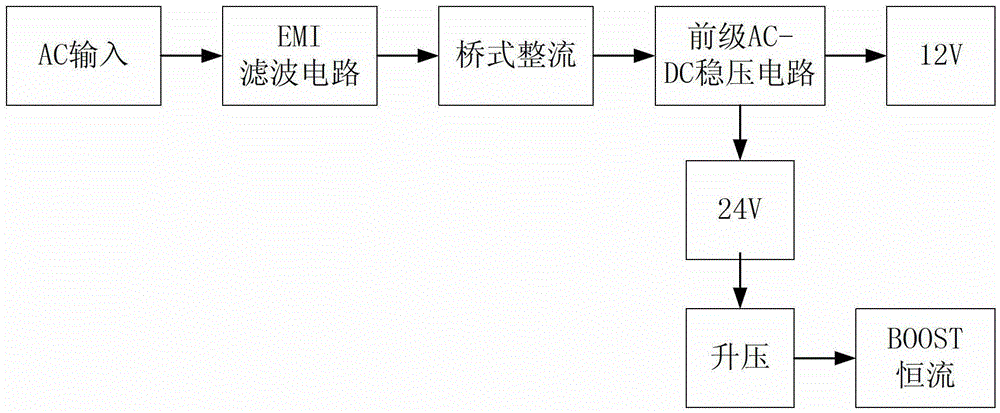

A short-circuit protection circuit and backlight technology, which is applied in the direction of protection against overcurrent, can solve the problems of over-power consumption damage of circuit components, no automatic isolation protection, high price, etc., and achieve the effect of avoiding over-power consumption damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

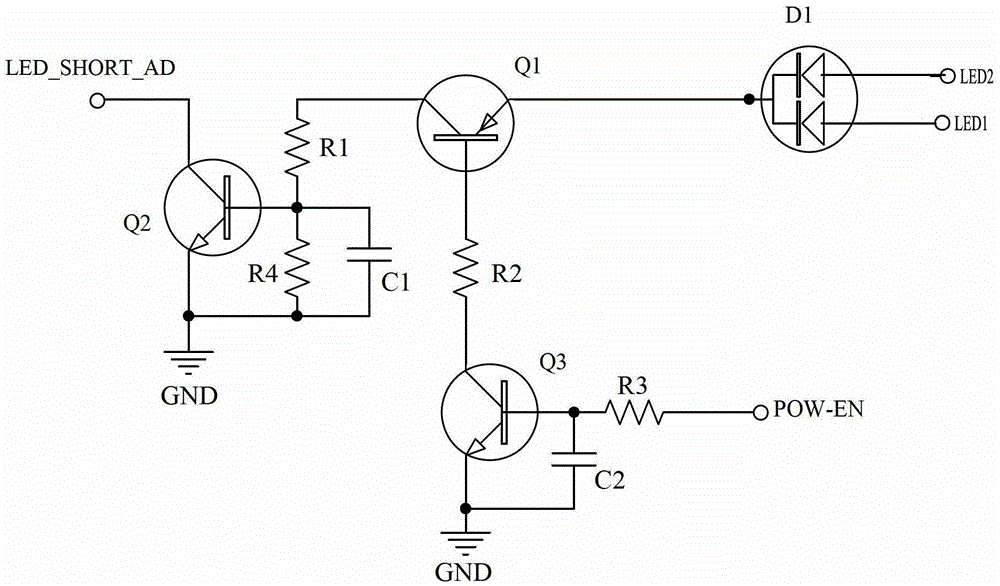

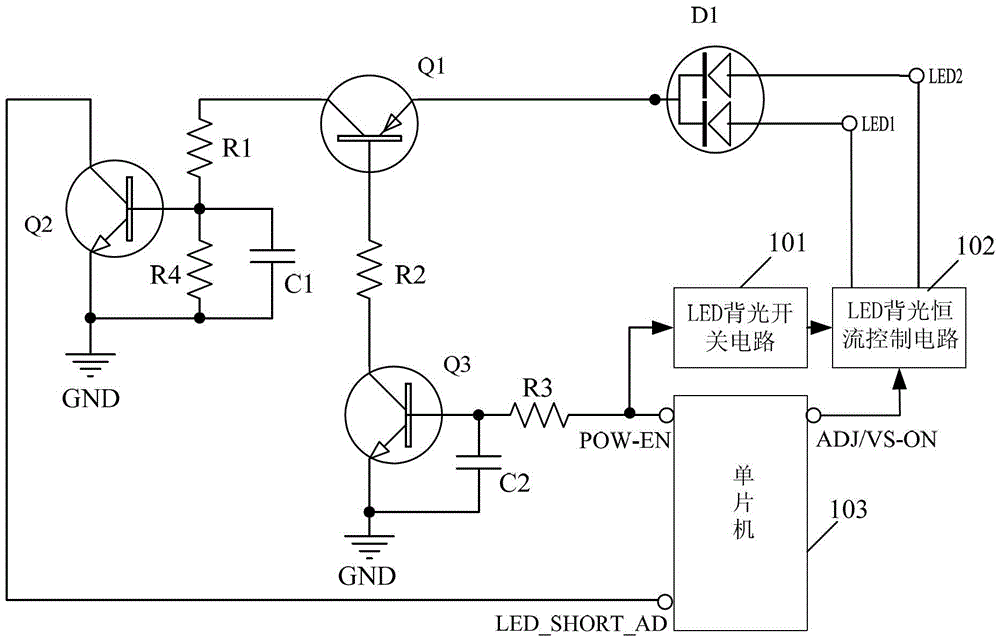

[0034] Please refer to figure 2 , is a circuit diagram of the first embodiment of the LED backlight short-circuit protection circuit of the present invention. The LED backlight short-circuit protection circuit includes a first transistor Q1, a second transistor Q2 and a third transistor Q3, wherein:

[0035] The emitter of the first triode Q1 is correspondingly connected to the cathode of the LED load through the diode D1 (it can be understood that when the LED load has only one way, the emitter of the first triode Q1 can be connected to the negative pole of the LED load without passing through the diode D1 directly connected to the load), the collector is grounded through the series resistors R1 and R4, and the connection point of the resistors R1 and R4 is connected to the base of the second transistor Q2, and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com