Carbon-carried palladium oxide catalyst, preparation method thereof and application thereof

A palladium oxide and catalyst technology, which is applied in the field of new carbon-supported palladium oxide catalyst and its preparation, can solve the problems of metal active component loss and weak interaction, and achieve the effect of simple preparation method, high dispersion and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

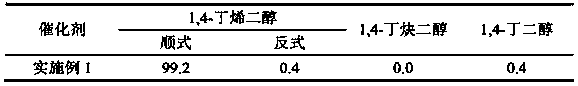

Embodiment 1

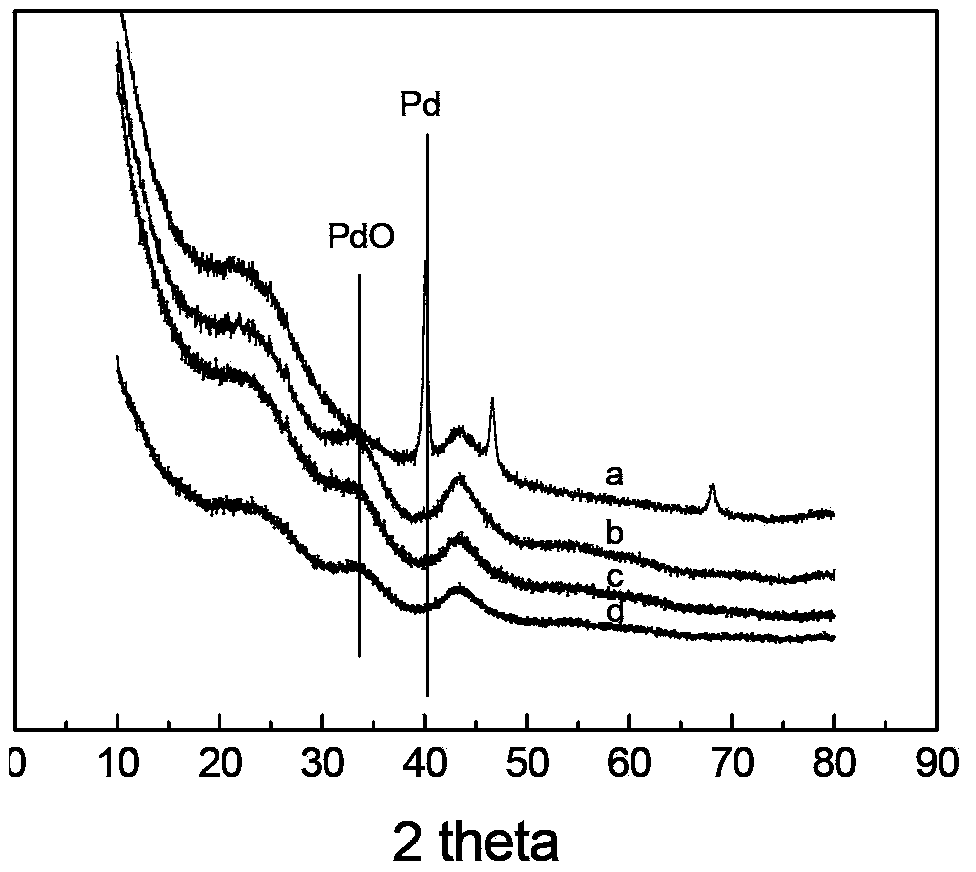

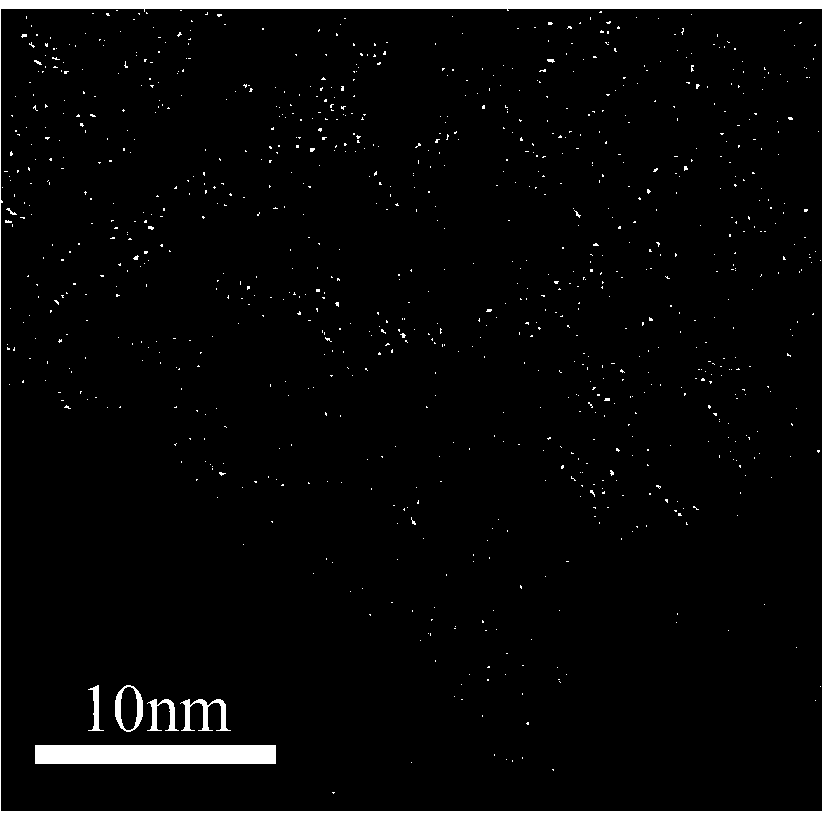

[0032] Pipette 4 mL of chloropalladium acid (H 2 PdCl 4 ) aqueous solution in 20mL deionized water at 10°C, and then slowly add NaOH solution (2wt%) dropwise under stirring to adjust the pH value to 5.0 to obtain a palladium oxide hydrate solution. Another 4.00 g of coconut shell activated carbon and 50 mL of deionized water were prepared into a slurry, and stirred at a constant temperature of 10° C. for half an hour. Then, the above-mentioned palladium oxide hydrate solution was added into the activated carbon slurry, and the stirring was continued at constant temperature for 4 hours. After the impregnation is completed, NaOH solution (2wt%) is added dropwise to adjust the pH value to 8-9. After continuing to stir for half an hour, filter and wash until the filtrate is neutral. According to XPS detection, based on palladium element, the content of divalent palladium in palladium oxide accounts for 83.6%, and palladium accounts for 16.4%.

Embodiment 2

[0034] Pipette 4 mL of palladium chlorate (H 2 PdCl 4 ) aqueous solution in 20mL deionized water at 15°C, and then slowly add NaOH solution (2wt%) dropwise under stirring to adjust the pH value to 5.5 to obtain a palladium oxide hydrate solution. Another 4.00 g of coconut shell activated carbon and 50 mL of deionized water were prepared into a slurry, and stirred at a constant temperature of 15° C. for half an hour. Then, the above-mentioned palladium oxide hydrate solution was added into the activated carbon slurry, and the stirring was continued at constant temperature for 4 hours. After the impregnation is completed, NaOH solution (2wt%) is added dropwise to adjust the pH value to 8-9. After continuing to stir for half an hour, filter and wash until the filtrate is neutral. That is, a carbon-supported palladium oxide catalyst (loading capacity: 5 wt %) was obtained. According to XPS detection, based on palladium element, the content of divalent palladium in palladium ox...

Embodiment 3

[0036] Pipette 4 mL of chloropalladium acid (H 2 PdCl 4) aqueous solution in 20mL deionized water at 20°C, and then slowly add NaOH solution (2wt%) dropwise under stirring to adjust the pH value to 6.0 to obtain a palladium oxide hydrate solution. Another 4.00g of coconut shell activated carbon and 50mL of deionized water were prepared into a slurry, and stirred at a constant temperature of 20°C for half an hour. Then, the above-mentioned palladium oxide hydrate solution was added into the activated carbon slurry, and the stirring was continued at constant temperature for 5 hours. After the impregnation is completed, NaOH solution (2wt%) is added dropwise to adjust the pH value to 8-9. After continuing to stir for half an hour, filter and wash until the filtrate is neutral. That is, a carbon-supported palladium oxide catalyst (loading capacity: 5 wt %) was obtained. According to XPS detection, based on palladium element, the content of divalent palladium in palladium oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com