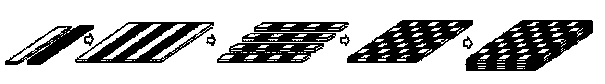

Checkered art bamboo board and method for manufacturing same

A production method and grid technology, which is applied in the field of furniture and interior decoration art materials, can solve problems affecting the development of the furniture industry, and achieve the effect of maintaining fine texture, simple preparation method and good artistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for making a square art bamboo board, comprising the following steps:

[0021] (1) Bamboo selection: choose moso bamboo with a bamboo age of 4 years and straight stalks;

[0022] (2) Making bamboo slices: Bamboo stalks are made into bamboo slices, the thickness is 4mm, and the planing is even;

[0023] (3) Cooking, bleaching or carbonization: Part of the bamboo slices are pressure-cooked and bleached, the cooking time is 5 hours, the pressure is 0.5MPa, and the cooked bamboo slices are dried until the moisture content of the bamboo slices is 7%. The drying temperature is 60°C; another part of the bamboo slices is carbonized, the carbonization temperature is 100°C, the pressure is 0.3MPa, and the time is 3 hours;

[0024] (4) Fine planing: the bamboo green and bamboo yellow of the cooked, bleached or carbonized bamboo chips are planed clean, and the accuracy of the thickness is kept within ±0.2mm;

[0025] (5) Gluing: Urea-formaldehyde resin adhesive is used, ...

Embodiment 2

[0033] A method for making a square art bamboo board, comprising the following steps:

[0034] (1) Bamboo selection: choose moso bamboo with a bamboo age of 6 years and straight stalks;

[0035] (2) Making bamboo slices: Bamboo stalks are made into bamboo slices, with a thickness of 6mm and uniform planing;

[0036] (3) Cooking, bleaching or carbonization: Part of the bamboo slices are pressure-cooked and bleached, the cooking time is 7 hours, the pressure is 0.9MPa, and the cooked bamboo slices are dried until the moisture content of the bamboo slices is 9%. The drying temperature is 70°C; another part of the bamboo slices is carbonized, the carbonization temperature is 105°C, the pressure is 0.4MPa, and the time is 4 hours;

[0037] (4) Fine planing: the bamboo green and bamboo yellow of the cooked, bleached or carbonized bamboo chips are planed clean, and the accuracy of the thickness is kept within ±0.2mm;

[0038] (5) Gluing: Urea-formaldehyde resin adhesive is used, an...

Embodiment 3

[0046] A method for making a square art bamboo board, comprising the following steps:

[0047] (1) Bamboo selection: choose moso bamboo with a bamboo age of 5 years and straight stalks;

[0048] (2) Bamboo slices: Bamboo stalks are made into bamboo slices with a thickness of 5mm and even planing;

[0049] (3) Cooking, bleaching or carbonization: Part of the bamboo slices are pressure-cooked and bleached, the cooking time is 6 hours, the pressure is 0.7MPa, and the cooked bamboo slices are dried until the moisture content of the bamboo slices is 8%. The drying temperature is 65°C; another part of the bamboo slices is carbonized, the carbonization temperature is 102°C, the pressure is 0.35MPa, and the time is 3.5 hours;

[0050] (4) Fine planing: the bamboo green and bamboo yellow of the cooked, bleached or carbonized bamboo chips are planed clean, and the accuracy of the thickness is kept within ±0.2mm;

[0051] (5) Gluing: Urea-formaldehyde resin adhesive is used, and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com