Micro-nano air floatation tank

A technology of micro-nano bubbles and air flotation tank, which is applied in flotation water/sewage treatment, grease/oily substance/floating matter removal device, liquid separation, etc. It can solve the problems of poor degreasing effect, inability to clean up sludge, and short residence time etc. to achieve good effect, easy maintenance, and improved removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

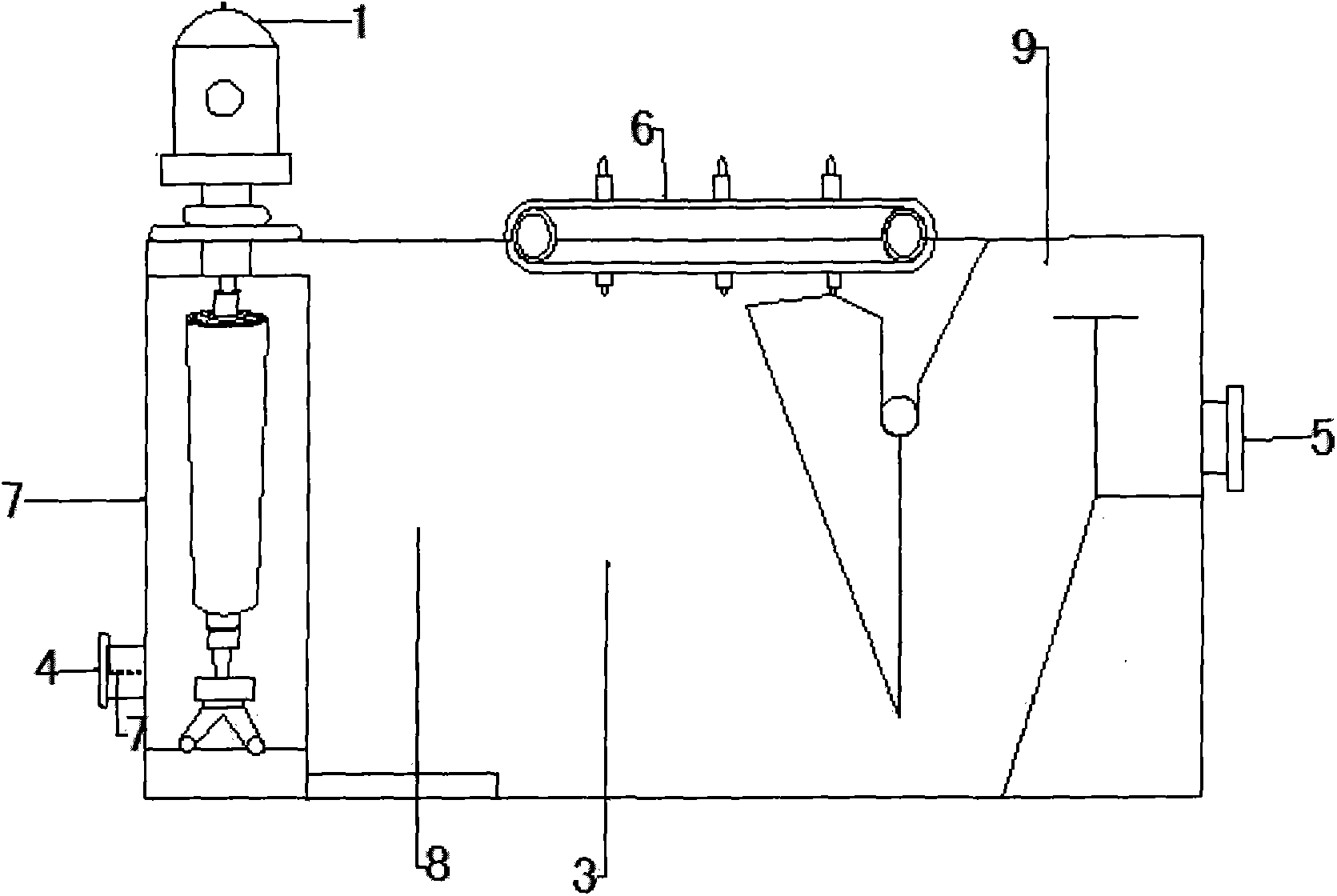

[0014] As shown in the figure, the sewage enters the main body along the tangential direction from the bottom of the contact chamber (8) in the partition wall (2) through the water inlet (4), and the micro-nano bubbles eject water flow containing a large number of micro-nano bubbles, which strengthens the swirl of the sewage. flow, so that the micro-nano bubbles can fully contact with the suspended matter in the influent, greatly improving the purification effect; the suspension carrying the micro-nano bubbles flows into the separation chamber (9) in the partition wall evenly from the top of the contact chamber (8) with the water flow, Suspended matter floats on the water surface of the separation chamber (9), a small amount of sludge sinks to the bottom, and the clean water at the bottom of the separation chamber (9) is discharged through the water outlet (5), and the slag scraper (6) installed on the top opening of the main body It can eliminate the scum generated on the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com