Sponge material of collagen from freshwater fish and preparation method thereof

A collagen sponge and freshwater fish technology, applied in the field of medical biomaterials, can solve the problems of inability to fully exert biological functions, wide distribution of fiber particle size, easy degradation, etc., and achieve resistance to enzymatic degradation and improvement of material morphological stability. Improves homogeneity and pore structure and distribution, reduces moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

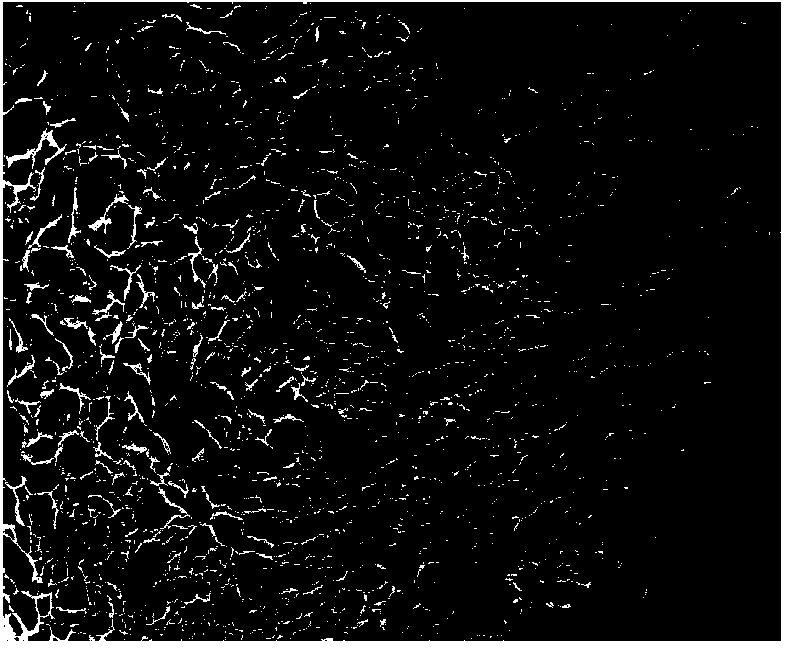

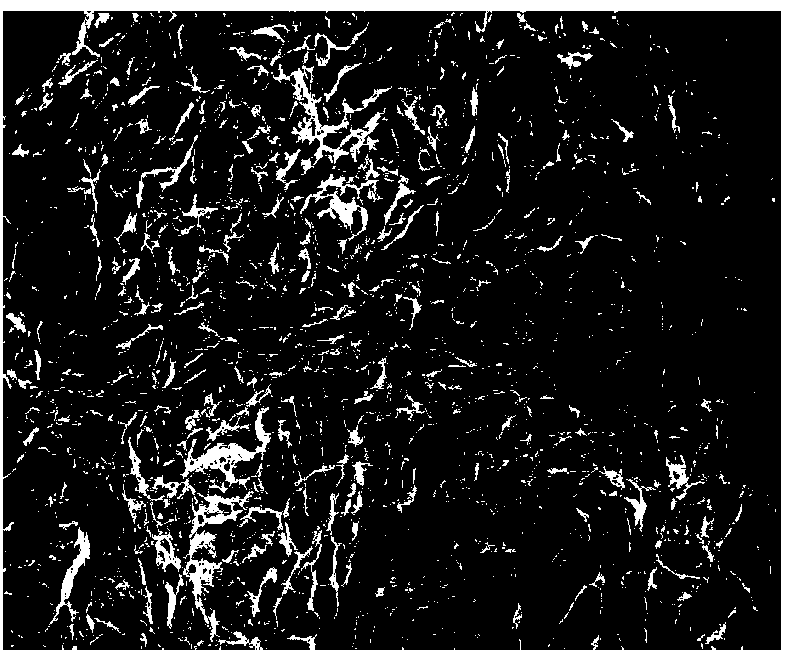

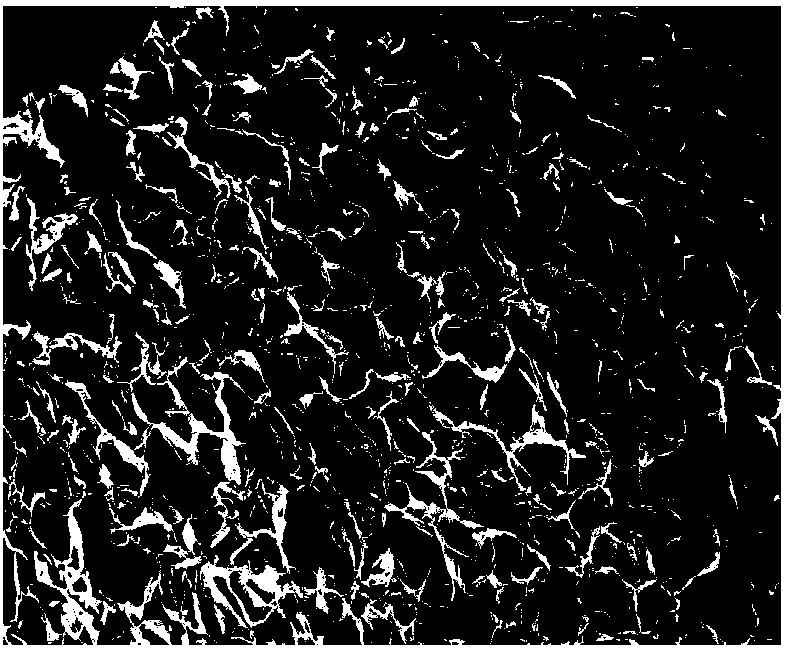

Image

Examples

Embodiment 1

[0037] Fresh grass carp skin is manually removed from attached fish meat and fish scales, washed and cut into small pieces. Add 15 times the volume of 0.1 mol / L NaOH solution to the treated fish skin raw material to soak for 24 hours, then fully wash with deionized water to neutrality and degrease with 15 times the volume of 10% n-butanol solvent for 24 hours. The degreased fish skin was repeatedly washed with deionized water, drained, and then extracted by stirring with 0.5 mol / L acetic acid solution (1:40, w / v) containing 2% pepsin. The extraction was repeated twice for 24 hours each time, separated and Combine the supernatants. Add NaCl to the supernatant to a salt concentration of 0.9mol / L, let it stand for 24 hours and then filter it. The filtered collagen precipitate is redissolved with 0.5mol / L acetic acid solution and dialyzed against 0.1mol / L acetic acid and distilled water in turn. , and finally freeze-dried to obtain grass carp skin collagen samples. (All the abov...

Embodiment 2

[0041] Using fresh herring skin as raw material to extract and purify enzyme-soluble collagen, the specific method is the same as that in Example 1.

[0042] Under the condition of 5°C, dissolve 150 mg of herring collagen with 0.01 mol / L hydrochloric acid and dilute the solution to 50 mL. Under ice bath conditions, slowly add 0.5 times the volume of 0.01mol / L PBS (pH7.4) to the above collagen solution, and then adjust the pH to 6.0 with 0.2mol / L hydrochloric acid. The volume of hydrochloric acid in mol / L is negligible, and the concentration of the collagen solution obtained at this time is 2 mg / mL. The preparation method of the PBS (pH7.4) of described 0.01mol / L is as follows: Na 2 HPO 4 12H 2 O: 3.473g; NaH 2 PO 4 12H 2 O: 0.226g; NaCl: 9.0g; triple distilled water: 1000mL.

[0043] Then, the collagen solution was ultrasonically treated at 22° C. for 20 minutes, with an ultrasonic frequency of 45 Hz and a power of 60 W. After ultrasonic treatment, adjust the pH of the...

Embodiment 3

[0045] Using fresh bighead carp skin as raw material to extract and purify enzyme-soluble collagen, the specific method is the same as that in Example 1.

[0046] At 10°C, 400 mg of bighead carp collagen was dissolved with 0.1 mol / L acetic acid and the solution was adjusted to 50 mL to obtain a collagen solution with a concentration of 8 mg / mL. Under ice-bath conditions, an equal volume of 0.01 mol / L PBS (pH 7.4) was slowly added to the above collagen solution, and then the pH was adjusted to 6.3 with 0.5 mol / L acetic acid. Since the volume of 0.5 mol / L acetic acid used to adjust the pH is negligible, the concentration of the obtained collagen solution at this time is 4 mg / mL. The preparation method of the PBS (pH7.4) of described 0.01mol / L is as follows: Na 2 HPO 4 12H 2 O: 3.473g; NaH 2 PO 4 12H 2 O: 0.226g; NaCl: 9.0g; triple distilled water: 1000mL.

[0047] Then, the collagen solution was ultrasonically treated at 24° C. for 50 minutes with an ultrasonic frequency ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap