Modified graphene/bismaleimide resin composite material and preparation method thereof

A technology of double-horse resin and composite materials, which is applied in the field of modified graphene/double-horse resin composite materials and its preparation, can solve problems such as poor dispersion, poor resin compatibility, and easy agglomeration, and achieve improved interfacial bonding performance and enhanced High solubility and toughness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

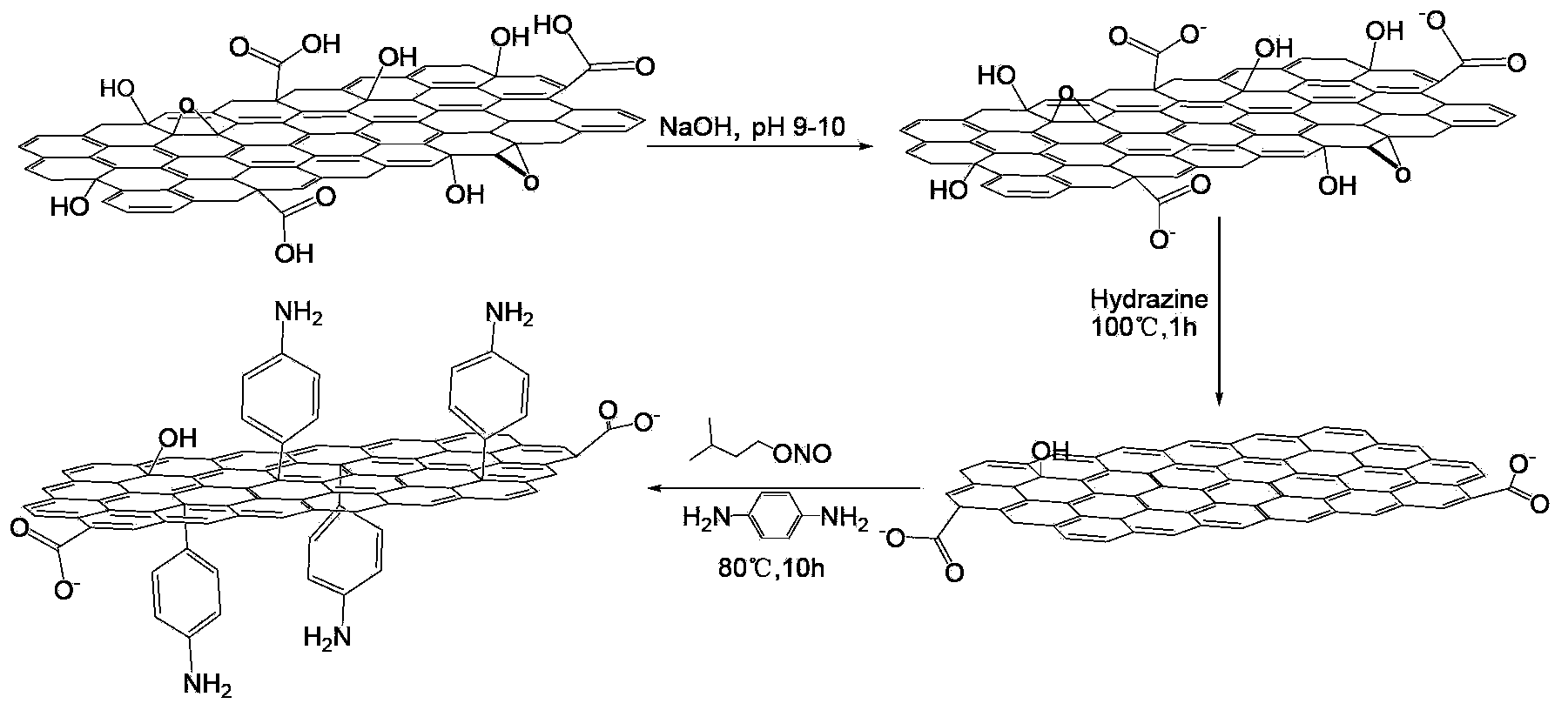

[0030] The present invention proposes a preparation method of a modified graphene / shuangma resin composite material, combined with the attached figure 1 , including the following steps:

[0031] Step 1: Preparation of graphite oxide:

[0032] (1) Take graphite powder, KNO 3 The powder is mixed with concentrated sulfuric acid (concentration: 75wt%~98.3wt%), and the mixing ratio is 1.5~2g KNO per 1.5g graphite powder 3 Powder, 65~69ml concentrated sulfuric acid, add KMnO when the obtained mixture is heated to 35~40℃ in water bath 4 Powder, the addition ratio is 8.0~9.5g KMnO per 1.5g graphite 4 , stir magnetically at 100-300r / min, and react for more than 6 hours; then slowly add deionized water to the mixture for the first time, and adjust the temperature of the water bath to 60°C-70°C, react for 25-40min, and then add Add deionized water for the second time, the amount of deionized water added for the first and second time is still added at the ratio of 100-200ml and 200-40...

Embodiment 1

[0046] Adopt the method provided by the invention to prepare the modified graphene / double horse resin composite material that mass percent composition is 0.1%, concrete steps are as follows:

[0047] The first step, graphite oxide preparation:

[0048] Take graphite powder, KNO 3 The powder is mixed with concentrated sulfuric acid (concentration is 98.3wt%), and the mixing ratio is to add 1.5g KNO to every 1.5g graphite powder 3 powder, 67ml of concentrated sulfuric acid, add KMnO4 powder when the resulting mixture is heated to 40°C in a water bath, and the addition ratio is 9.0g of KMnO for every 1.5g of graphite 4 , magnetically stirred at 220r / min, and reacted for more than 6h; then slowly added 100mL deionized water to the mixture, and adjusted the temperature of the water bath to 60°C, and reacted for 25min, then added 300ml deionized water to it, and continued to react for 4min After that, add 9ml dropwise to the mixed liquid with a concentration of 30wt%H 2 o 2 , un...

Embodiment 2

[0055] Adopting the preparation method provided by the invention to prepare the modified graphene / double horse resin composite material whose mass percentage concentration of modified graphene is 0.2%, the concrete steps are as follows:

[0056] Step 1: Preparation of graphite oxide:

[0057] (1) Take graphite powder, KNO 3 The powder is mixed with concentrated sulfuric acid (concentration: 75wt%), and the mixing ratio is to add 1.5KNO to every 1.5g of graphite powder 3 powder, 65ml of concentrated sulfuric acid, when the resulting mixture was heated to 35°C in a water bath, KMnO was added 4 Powder, the addition ratio is 9.5g KMnO per 1.5g graphite 4 , magnetically stirred at 100r / min, and reacted for more than 6h; then slowly added deionized water to the mixture for the first time, and adjusted the temperature of the water bath to 70°C, and reacted for 40min, then added deionized water to it for the second time , the first and second additions of deionized water are still ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com