Water-based PET (polyethylene terephthalate) undercoat paint, and preparation method and application thereof

A water-based and coating technology, applied in the direction of polyester coatings, coatings, etc., can solve the problems of poor adhesion of UV light-cured inks, and achieve the effect of easy industrial production, safe manufacturing and use, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

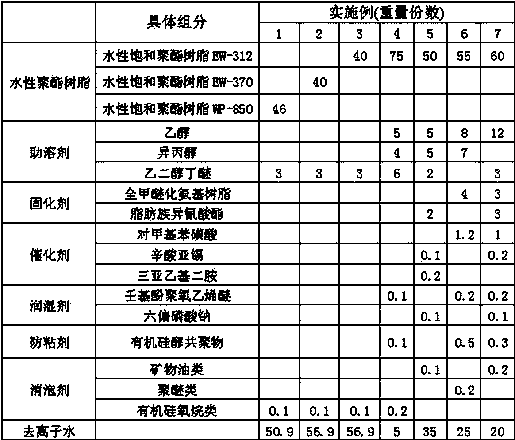

[0047] The water-based PET primers of Examples 1-3 include the components and parts by weight shown in Table 1. Its preparation method comprises the following steps:

[0048] A. Put the co-solvent and deionized water into the reaction kettle, and stir under the control dispersion speed of 300r / min;

[0049] B. Control the dispersion speed to 500r / min, add water-based polyester resin, stir for 20 minutes to make the water-based polyester resin mix evenly, and finally add defoamer to disperse evenly, and then get water-based PET primer.

[0050] The application of the water-based PET primer of the present embodiment is as follows:

[0051]The obtained water-based PET primer is coated on the PET film with a 200-mesh steel roller, dried continuously at a temperature of 120-130° C. for 13-15 seconds, and then coated with UV light-curable ink. After testing, when the water-based PET primer is not pre-coated, the UV light-curable ink printed on the PET c...

Embodiment 4

[0053] The water-based PET primer in Example 4 includes the components and parts by weight shown in Table 1. Its preparation method comprises the following steps:

[0054] A. Put the wetting agent, co-solvent, and deionized water into the reaction kettle, and control the dispersion speed to 300r / min and stir for 10min;

[0055] B. Control the dispersion speed to 500r / min, add water-based polyester resin, anti-sticking agent, and defoamer, and stir for 20 minutes to mix the water-based polyester resin evenly to obtain a water-based PET primer.

[0056] The application of the water-based PET primer of the present embodiment is as follows:

[0057] The obtained water-based PET primer is coated on the PET film with a 200-mesh steel roller, dried continuously at a temperature of 115-125° C. for 13-15 seconds, and then coated with UV light-curable ink. After testing, when the water-based PET primer is not pre-coated, the UV light-curable ink printed on the PET...

Embodiment 5

[0059] The water-based PET primer in Example 5 includes the components and parts by weight shown in Table 1. Its preparation method comprises the following steps:

[0060] A. Put the catalyst, wetting agent and co-solvent into the reaction kettle, control the dispersion speed to 300r / min and stir for 5 minutes, add curing agent and deionized water, and control the dispersion speed to 500r / min and stir for 10 minutes;

[0061] B. Keep the dispersion speed at 500r / min, add water-based polyester resin, stir for 30 minutes to mix the water-based polyester resin evenly, finally add defoamer, and then disperse at 500r / min for 10 minutes to obtain water-based PET primer.

[0062] The application of the water-based PET primer of the present embodiment is as follows:

[0063] The obtained water-based PET primer is coated on the PET film with a 220-mesh steel roller, dried continuously at a temperature of 105-115° C. for 12-15 seconds, and then coated with UV light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com