Blower main shaft bearing lubricating grease and preparation method thereof

A spindle bearing and grease technology, applied in the field of grease, can solve the problems of high operating costs, non-biodegradable, and short service life of wind power enterprises, and achieve good waterproof and anti-corrosion performance, high load-carrying capacity, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

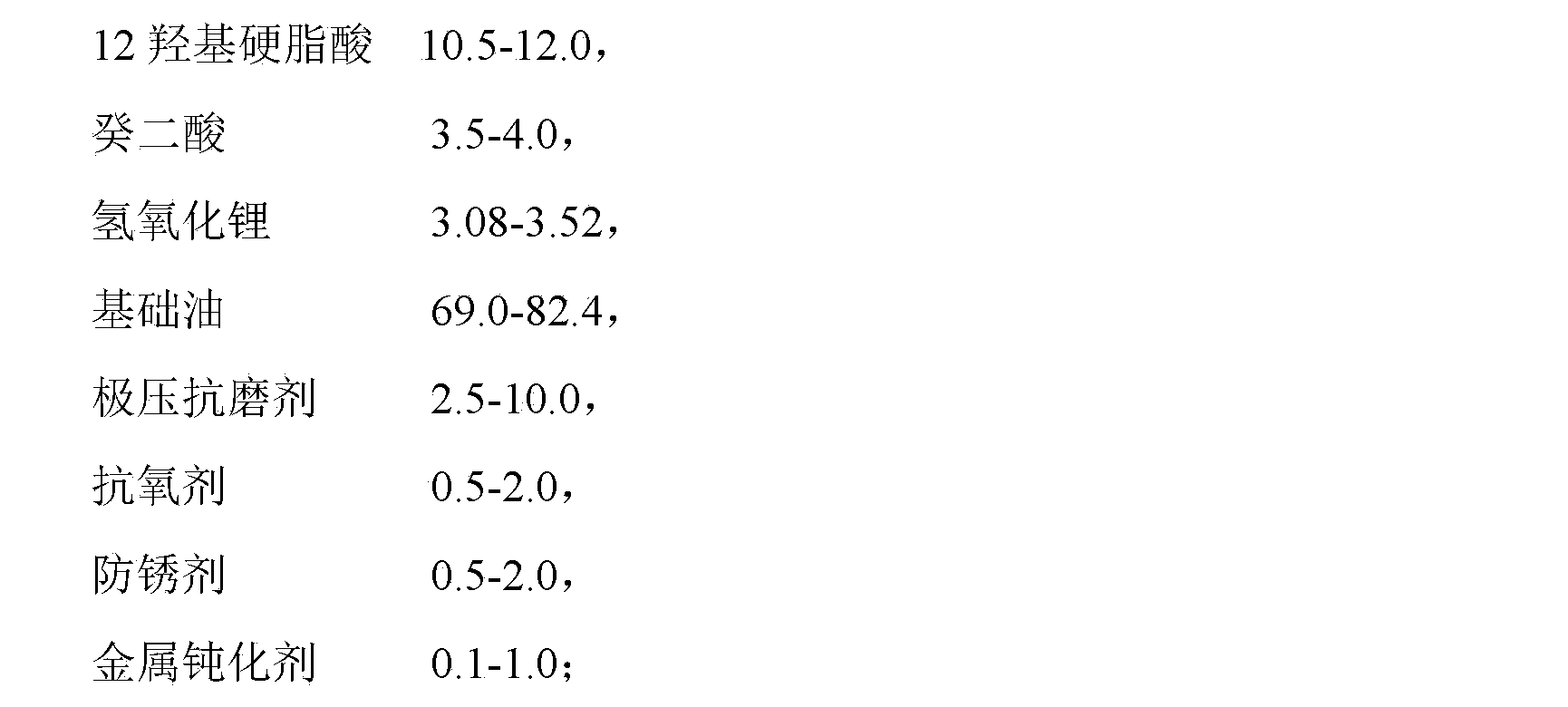

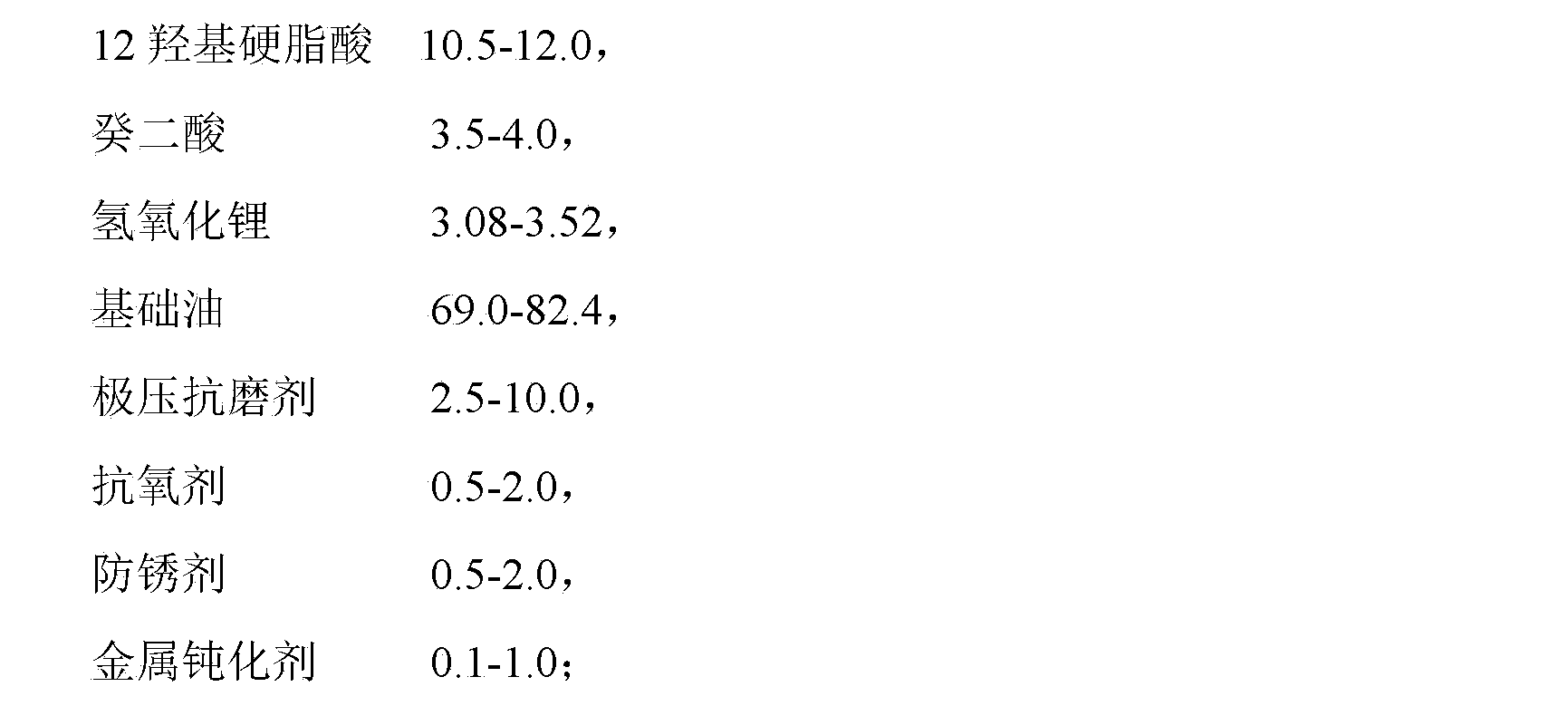

[0024] Fan shaft bearing grease, including the following components blended in proportion by weight:

[0025] 12 hydroxystearic acid 10.5kg, sebacic acid 3.5kg, lithium hydroxide 3.08 kg, base oil 77.8 kg, extreme pressure antiwear agent 6 kg, antioxidant 1 kg, rust inhibitor 1 kg, metal deactivator 0.2 kg.

[0026] The production method of fan spindle bearing grease, the specific operation steps are:

[0027] 1) Add mixed base oil with a weight percentage of 58-62% in the saponification kettle, heat up and stir at a speed of 30-60 rpm, add 12 hydroxystearic acid at 80°C, heat up to 90-100°C, and 12 hydroxystearic acid is completely dissolved;

[0028] 2) Mix lithium hydroxide and water according to 1: (5-7) to make a lithium hydroxide suspension, take 40-45% of the lithium hydroxide suspension, and slowly add it to the mixture obtained in step 1), Keep warm at 95-100°C and stir for saponification, the saponification time is 60-80 minutes; continue to heat up to 150-165°C, ...

Embodiment 2

[0032] Fan spindle bearing grease, including the following components blended by weight: 12 hydroxystearic acid 11.25kg, sebacic acid 3.75kg, lithium hydroxide 3.3kg, base oil 74.6kg, extreme pressure antiwear agent 9kg, anti Oxygen agent 0.5kg, rust inhibitor 0.5kg, metal deactivator 0.4kg.

[0033] The production method of fan main shaft bearing lubricating grease is the same as embodiment 1.

Embodiment 3

[0035] Fan main shaft bearing grease contains the following components in parts by weight:

[0036] 129kg of 12 hydroxystearic acid, 49kg of sebacic acid, 3.52 parts of lithium hydroxide 9kg, 71.4 parts of base oil 9kg, 9 parts of extreme pressure antiwear agent 9kg, antioxidant 1.59kg, rust inhibitor 9kg, metal deactivator 0.69 kg.

[0037] The production method of fan main shaft bearing lubricating grease is the same as embodiment 1.

[0038] In the above embodiment, the base oil is a mixture of dipentaerythritol ester, polyalphaolefin, and alkylnaphthalene, wherein the weight percentage is dipentaerythritol ester: 20%-25%; polyalphaolefin: 55%-60%; alkylnaphthalene: 15%-25%. The extreme pressure antiwear agent is a mixture of phenyl thiophosphonate, molybdenum oxysulfide dibutyl dithiocarbamate, and lead diamyl dithiocarbamate. The metal deactivator is a thiadiazole derivative, and the thiadiazole derivative is 2,5-bis(octyldithio)-1,3,4-thiadiazole. 12-Hydroxystearic A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com