Opening side skirt plate type on-duty flame stabilizer

A flame stabilizer and stabilizer technology, which is applied in the combustion method, combustion chamber, combustion equipment and other directions, can solve the problems of uneven temperature field of the stabilizer, high temperature in the recirculation zone, low temperature on both sides, etc., and achieves simple structure and flame. The effect of short length and uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

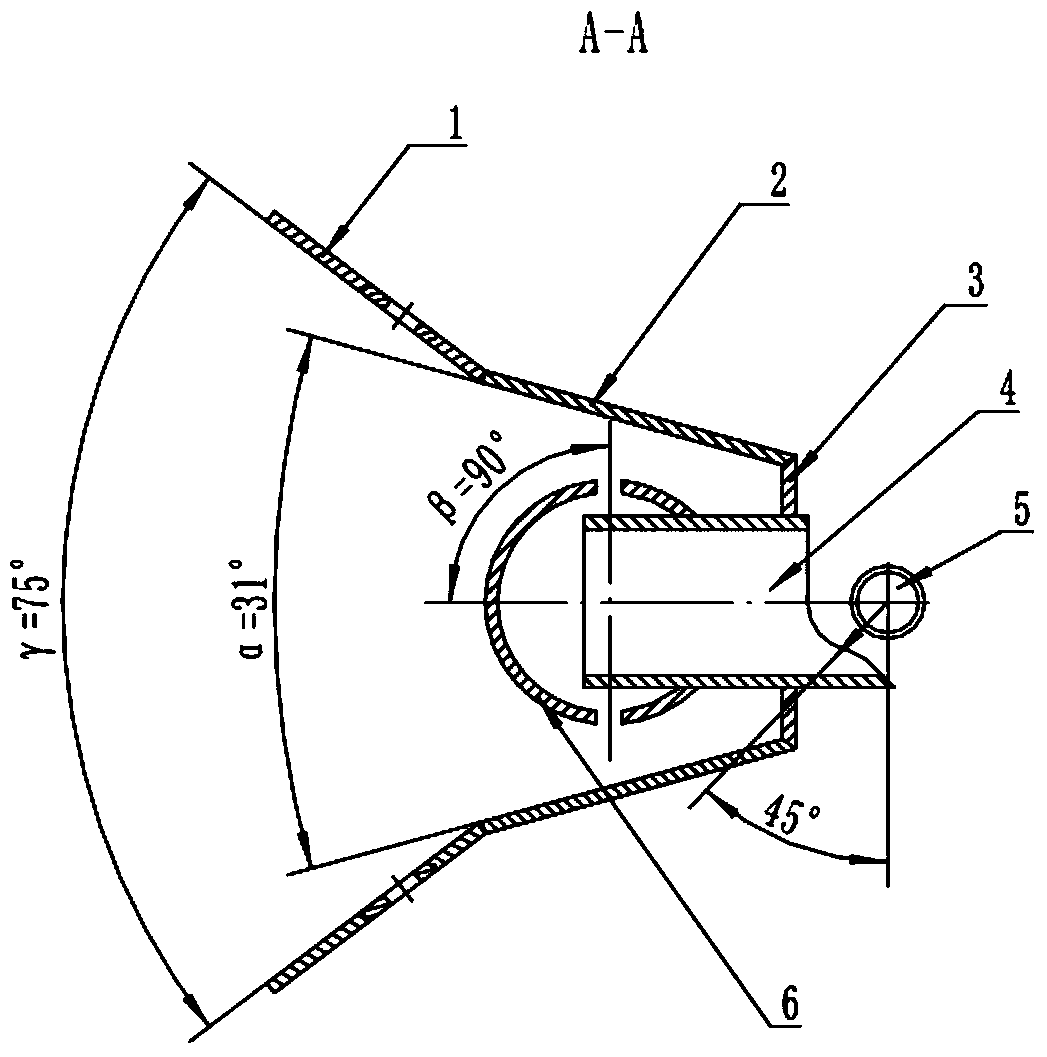

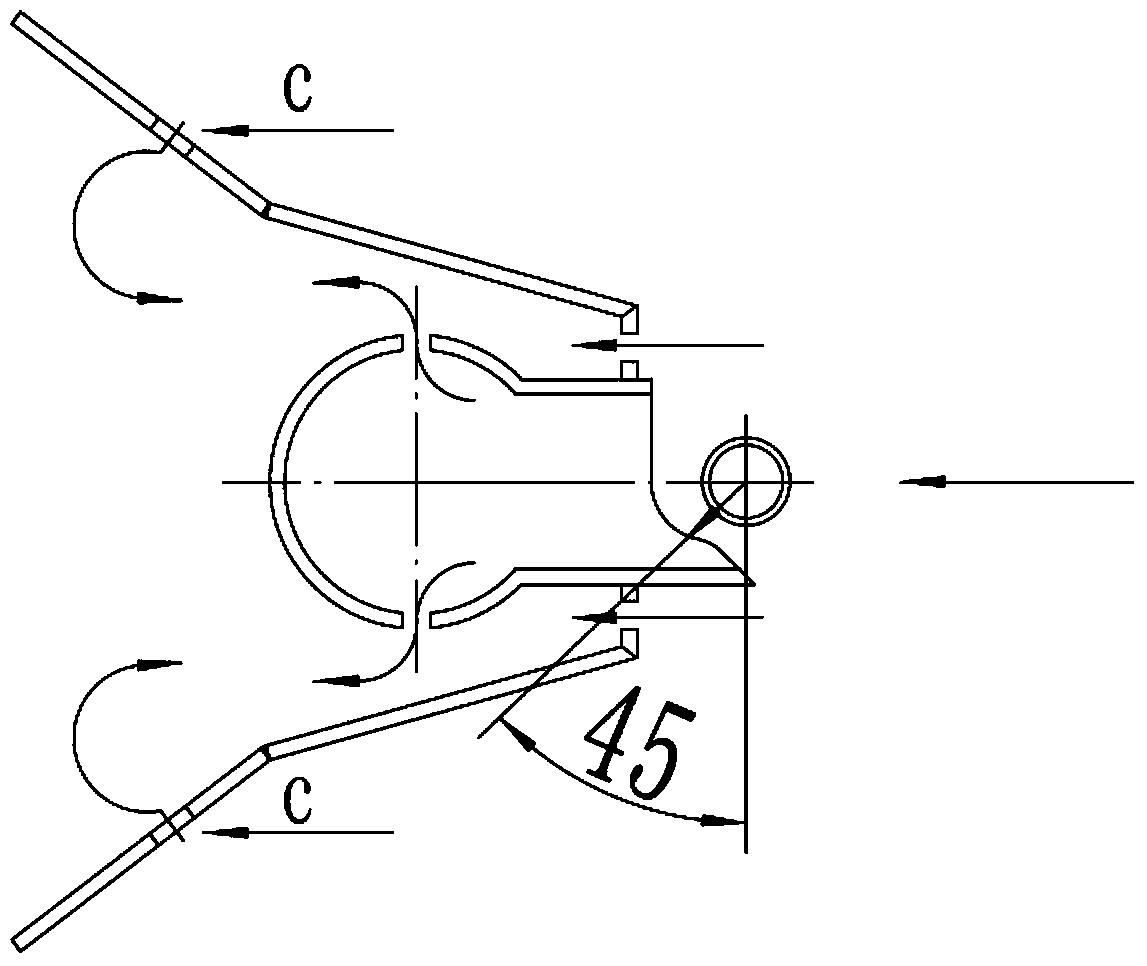

[0027] figure 1 , figure 2 It is a structural representation of the present invention. A perforated side apron type duty flame stabilizer of the present invention comprises a stabilizer perforated side apron 1, a stabilizer side plate 2, a stabilizer head panel 3, a stabilizer fuel distribution pipe intake pipe 4, and a direct injection rod 5 and stabilizer fuel distribution pipe 6.

[0028] figure 1 is a cross-sectional view, such as figure 1 , Stabilizer opening side skirt plate 1, stabilizer side plate 2, stabilizer head panel 3, stabilizer fuel distribution pipe 6, stabilizer fuel distribution pipe air inlet 4 is welding relationship, the fuel supply scheme is to adopt a A two-hole direct injection rod 5, on which there is a fuel injection hole with a diameter of 0.7 mm, the position of the fuel injection hole corresponds to the fuel distribution pipe intake pipe 4 of the flame stabilizer on duty, and the position of the fuel injection hole The direction of fuel inje...

Embodiment 2

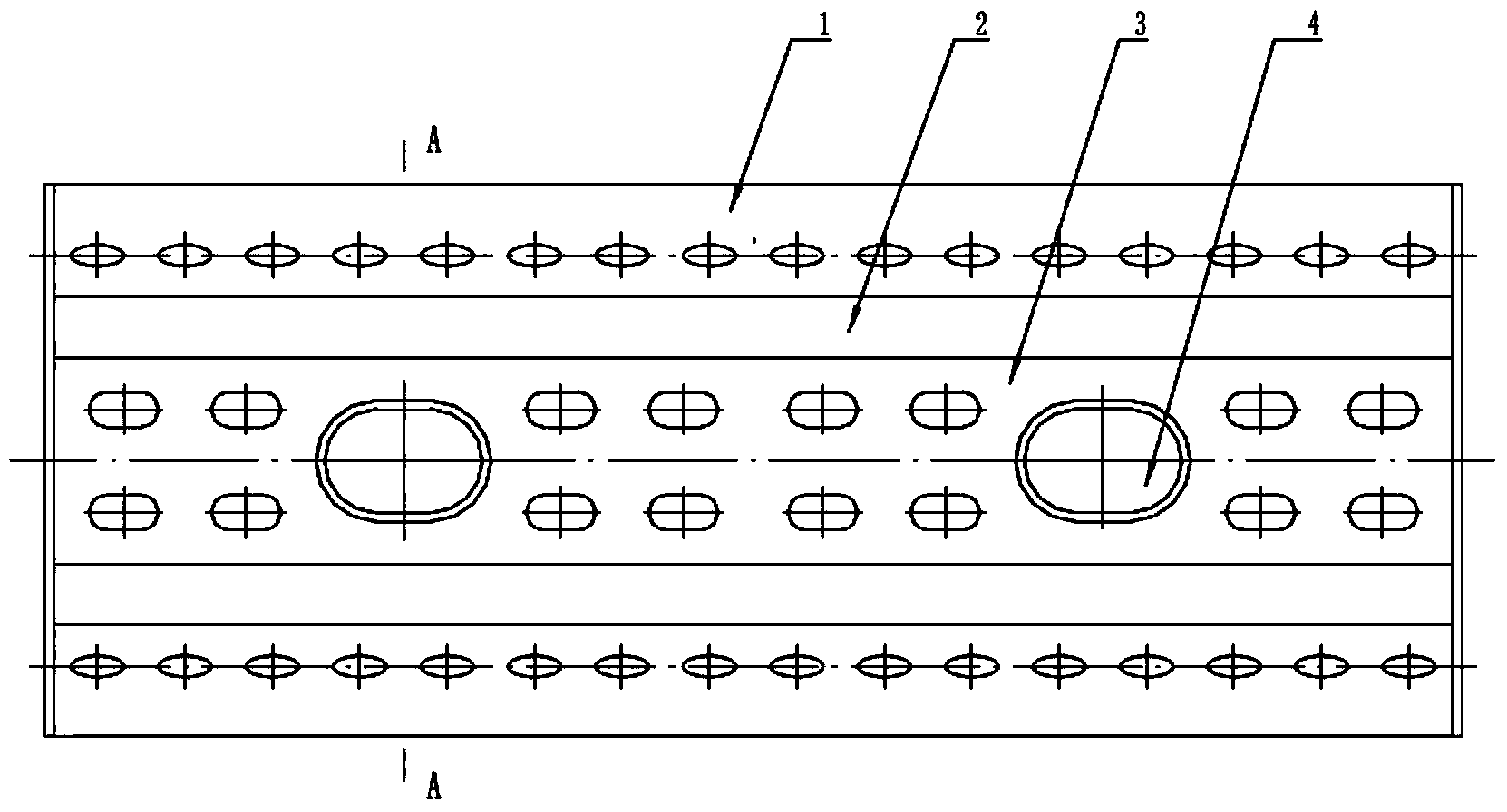

[0047] To open holes on the skirt plates on both sides of the stabilizer, two parameters need to be determined: one is the position of the hole; the other is the area of the hole. Different opening positions will cause different air mixing positions, which will have different effects on the flow field in the stable area behind the stabilizer, and then affect the combustion performance. Different opening areas determine the amount of air introduced. Different The amount of bleed air will affect the mixing effect on the rear temperature field, and will also affect the uniformity of the temperature field behind the stabilizer.

[0048] Two flame stabilizers with different structures are designed, and the specific design parameters of these two flame stabilizers are introduced in detail below.

[0049] The side skirt plate type flame stabilizer with openings proposed by the present invention has the same structural parameters in the part except the skirt plate: groove width, flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com