Electrical heating cast aluminum heat exchanger

A technology of heat exchangers and electric heating, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems affecting the vaporization speed and limiting the vaporization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

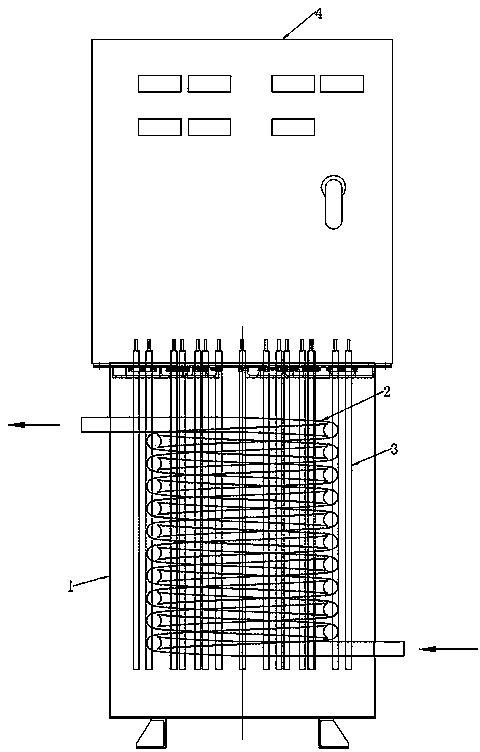

[0008] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like figure 1 Shown: an electric heating cast aluminum vaporization heat exchanger, including a shell 1, a coil 2 and a plurality of heating rods 3 are arranged in the shell 1, and all the heating rods 3 are connected with the control circuit and unified Control, while the control circuit is located inside the electric control cabinet 4 arranged on the upper part of the housing 1, and inside the housing 1, the cavity parts except the coil tube 2 and the heating rod 3 are filled with cast aluminum or cast aluminum alloy.

[0009] The working process of the electric heating cast aluminum gasification heat exchanger in the embodiment of the present invention is as follows: first, the liquid fluid to be vaporized is transported into the coil 2 through the inlet of the coil 2, and then the heating rod 3 is controlled to work by the control circuit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com