High-efficiency and energy-saving microwave cocoon drying machine

A microwave cocoon drying machine, high-efficiency and energy-saving technology, applied in the field of silkworm cocoon drying, can solve the problems affecting the comprehensive utilization and subsequent processing of silkworm chrysalis, the loss of cocoon silk sericin denatured silkworm chrysalis protein, and the inability to obtain fresh silkworm chrysalis. Small size, high heating uniformity, and the effect of preventing curing and denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

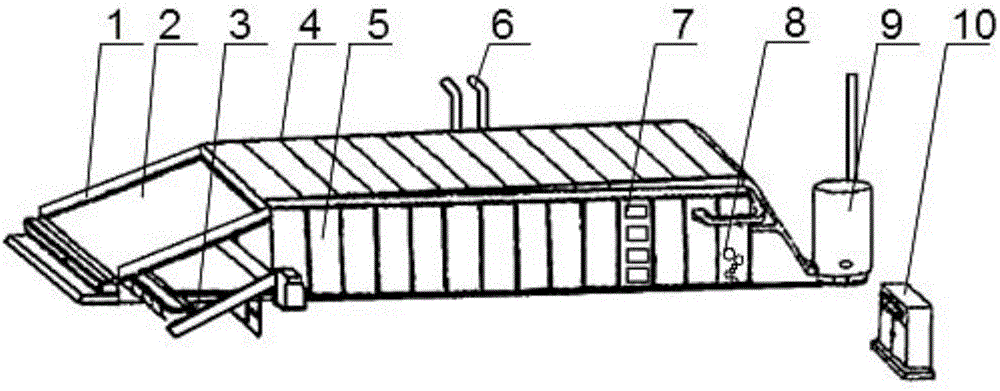

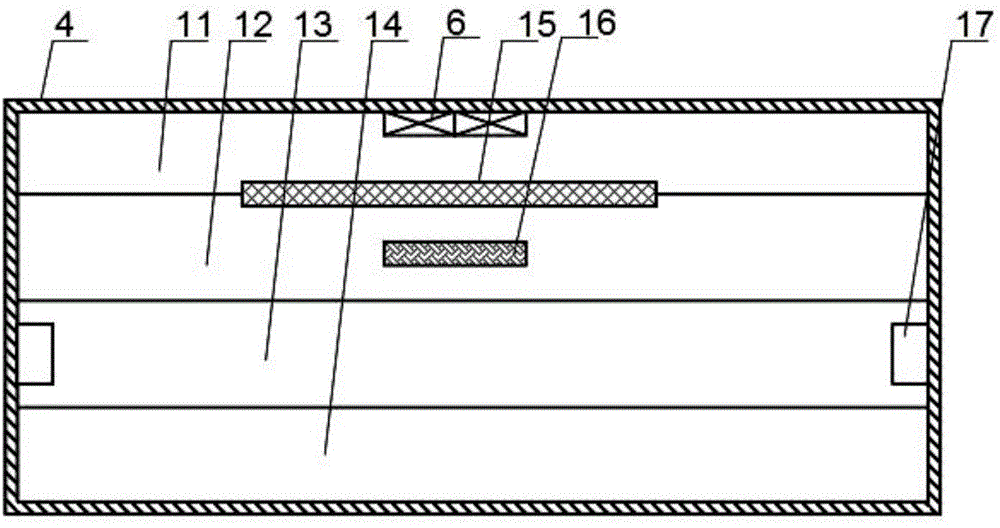

[0024] Such as figure 1 and figure 2 As shown, the high-efficiency and energy-saving microwave cocoon drying machine includes a microwave drying box 4, a microwave generator 15, a microwave suppressor 16, a material conveying system, a heating system 9, a control and detection system 10, and a moisture and heat exhausting system 6; microwave drying Casing 4 comprises cocoon-incoming box 11, pupa-killing box 12, balance box 13 and cocoon-out box 14 installed and connected successively from top to bottom, and air-cooling cooling device 17 is arranged in the balance box 13; Microwave generator 15 is installed in killing The top of chrysalis case 12; Microwave suppressor 16 is installed in the middle part of chrysalis killing case 12; Material conveying system comprises feeding device, discharging device 3, S type automatic mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com